V10k automatic 6. Maintenance

39

EN

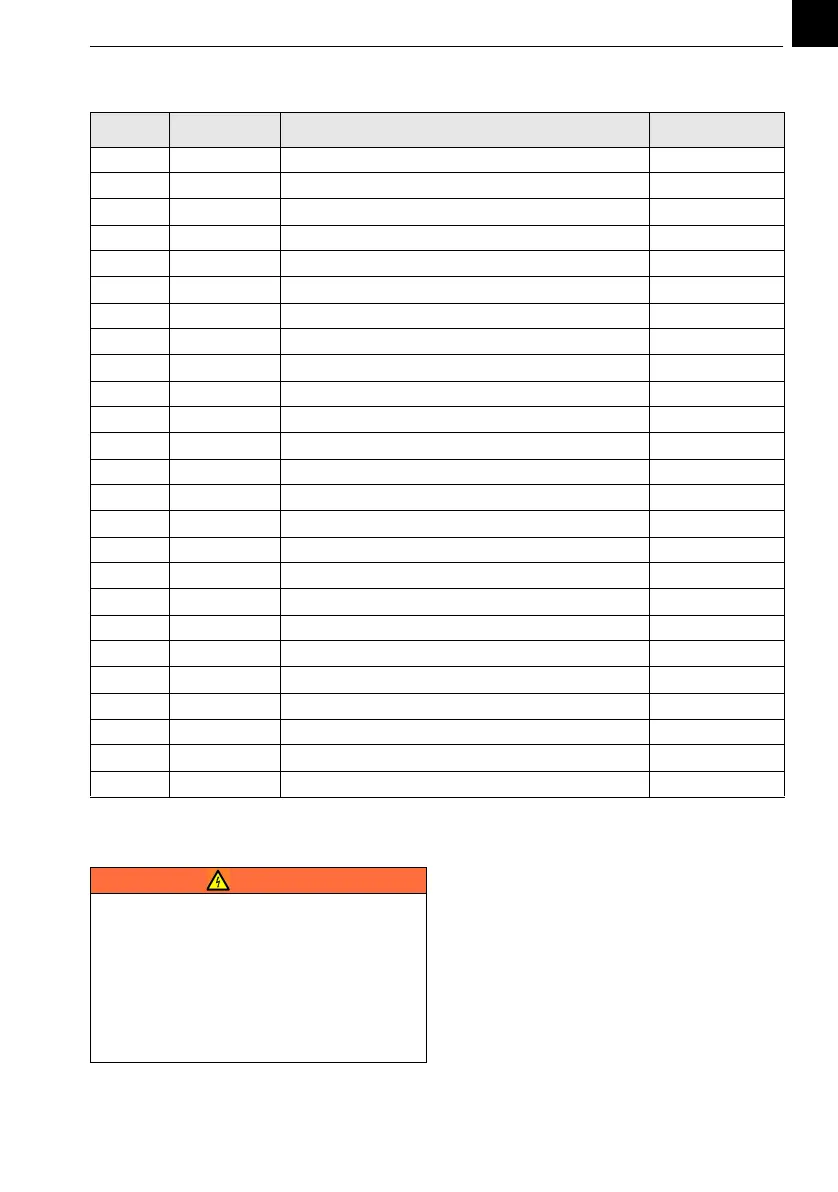

6.5.19 Maintenance kit W3T167028

for Injector ¾” anti‐syphon (W3T171370), 5 years

6.6 Positioner

6.6.1 Checking the positioner motor

(only by electrical specialists)

Check the motor winding with an ohmmeter:

1 Make sure the positioner is free from

voltage

2 Remove knob and screws, lift the cover

(see also 4.5.3)

3 Pull off the terminals 4/5/6

Pos. Part No. Description Quant.

0001 W3T159655 Inlet screw 1

0002 W3T168861 o-ring d 25 x 2,5 5

0003 W3T161434 o-ring d 8 x 2 5

0004 W3T159656 Valve stem 1

0005 W3T158460 Valve seat 5

0006 W3T169066 o-ring d 12,37 x 2,62 15

0007 W3T168988 o-ring d 68 x2 10

0008 W3T161483 Diaphragm 15

0009 W3T158461 Clamping nut 1

0010 W3T165194 Spring 1

0011 W3T168914 Spring 1

0012 W3T159657 Valve stem 5

0013 W3T172921 o-ring d 10 x 4 5

0014 W3T158545 Guide pin 2

0015 W3T169065 o-ring d 6,07 x 1,78 10

0018 W3T161484 Spring d 21,3 1

0019 W3T172724 o-ring d 20,22 x 3,53 5

0020 W3T169068 o-ring d 13,94 x 2,62 10

0021 W3T169073 o-ring d 21,89 x 2,62 5

0022 W2T503995 Special grease BARRIERTA L25DL, 9 gr 1

0024 W3T173010 o-ring d 28,17 x 3,53 5

0025 W3T172725 o-ring d 32,92 x 3,53 5

0026 W3T171695 Diaphragm 5

0027 W3T171257 Injector nozzle No.140 anti-syphon 1

0028 W2T507600 Tailway 'F' 1

WARNING

To avoid personal injury by electrical energy

only authorized and qualified electrical per-

sonnel may carry out works on electrical

parts of the system.

Make sure that the system is free from vol-

tage during the time of maintenance or

repair.

Pay attention to external voltage even if the

main switch is off.

Loading...

Loading...