34

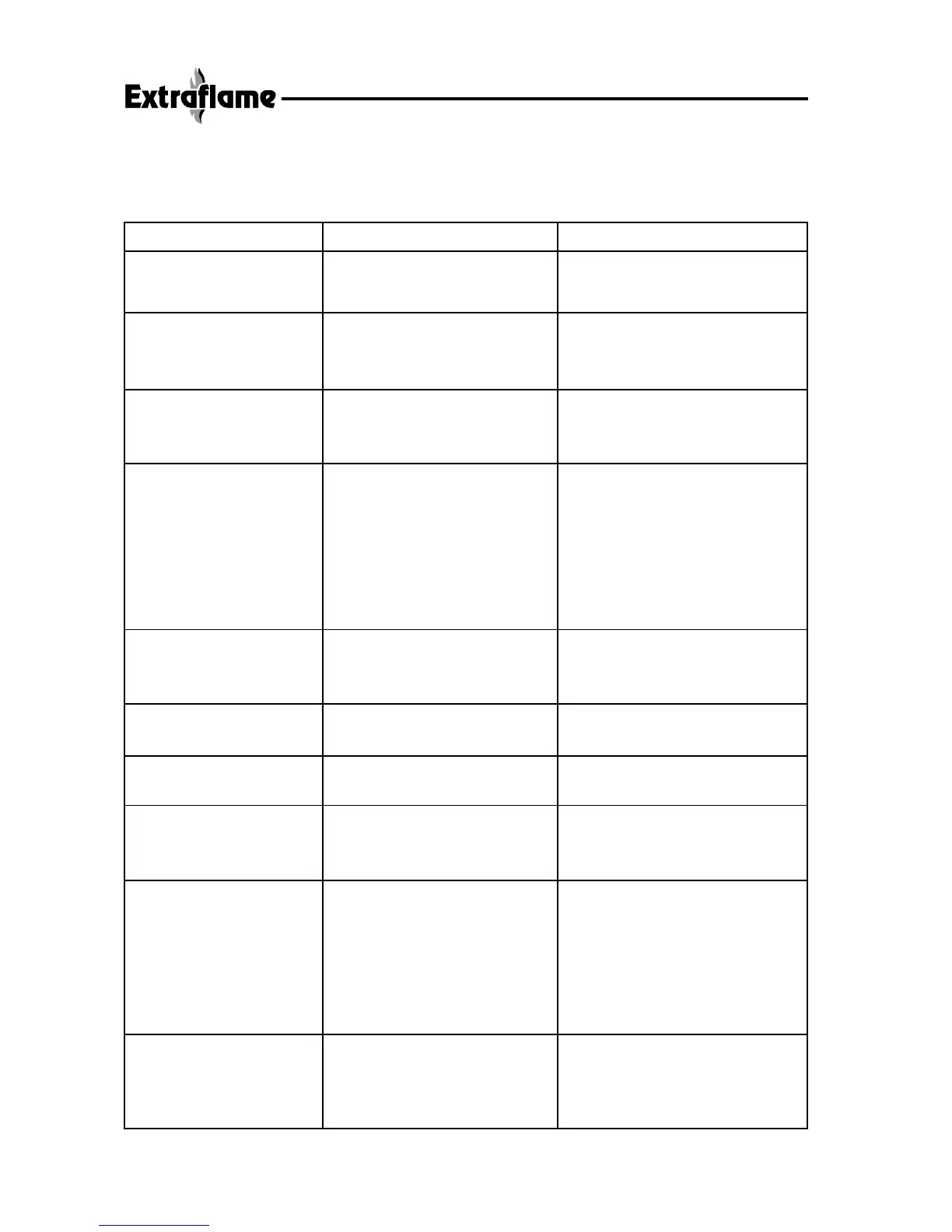

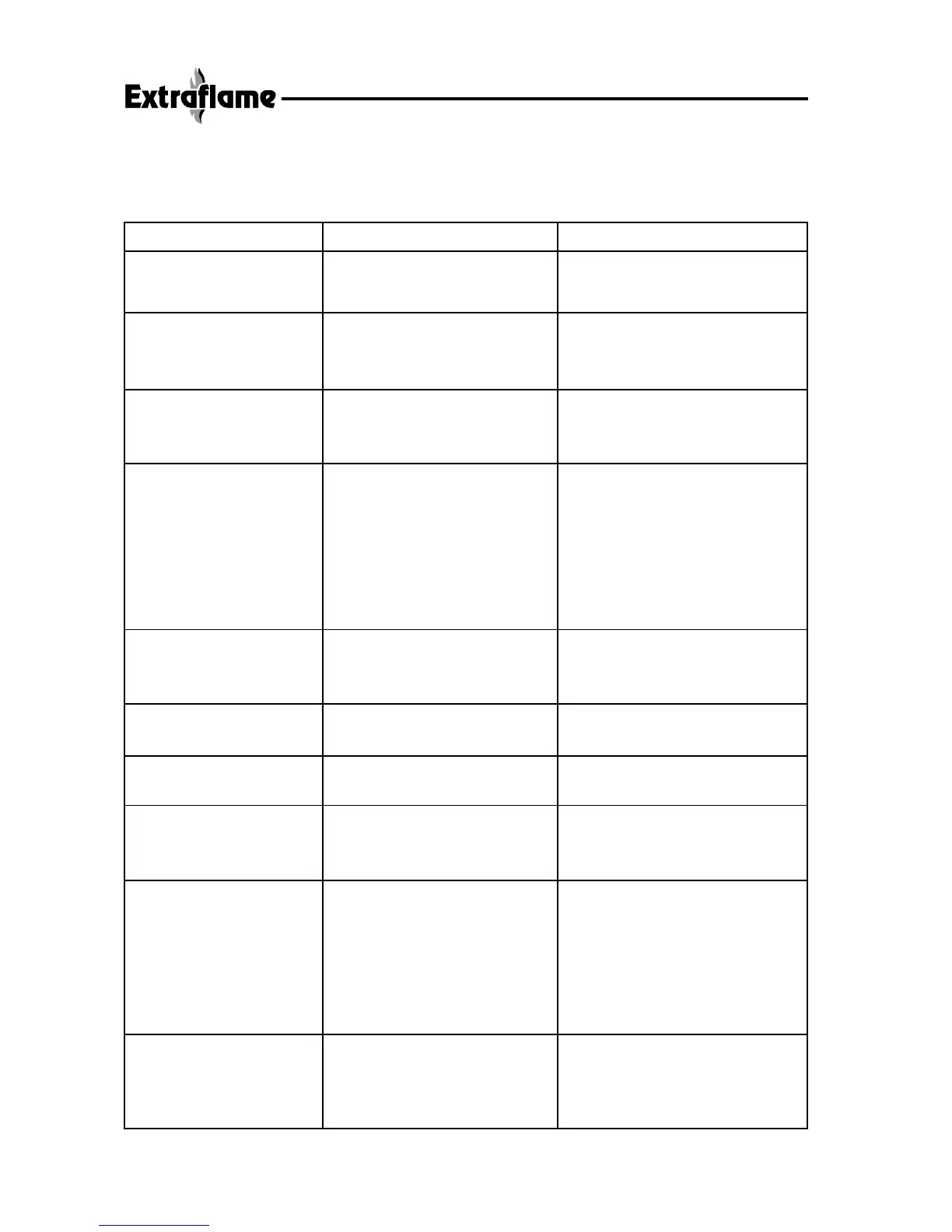

13.4 ALARM MESSAGES

If operating faults occur, the stove provides a control system which informs the user on the

display where the fault has occurred. The alarms are summarised in the following table:

Message on the display D1

Solution

- The fume motor is blocked

- The speed control probe is broken

- No power supply to the motor

Fum Fail

Replace the motor or check if there is

power supply

These operations must be carried out

by an authorised engineer

Fum tc

- The thermocouple is broken

- The thermocouple is disconnected

from the board

Check that the thermocouple is correctly

connected using the wiring plan on the

hopper or replace the component.

These operations must be carried out by

an authorised engineer

Hight temp

- Too full of pellets

- No power supply to the tangential

motor

Check the power supply

Replace the broken motor

Adjust the pellet feeding

These operations must be carried out

by an authorised engineer

Hight H2O

(only for Mod. IDRO)

- The circulation pump is blocked

- The power of the plant is lower than

0,9 m3/h

- The water plant is out of water

Check that there is power supply in the

pump.

Check that the pump impeller is not

blocked by limestone.

The plant is too big in relation to the

pump flow (add an additional pump).

Fill the plant up by means of the relative

feeding group.

Check there is no leakage causing the

emptying of the plant.

These operations must be carried out by

an authorised engineer.

Depr Fail

- The flue is obstructed

- The chamber is dirty

- The silicone tube is disconnected

Check that the flue and chamber are clean

Check the connection of the silicone tube

These operations must be carried out by

an authorised engineer

No acc

Raf

- No pellets in the hopper

- Lighting for the first time

Fill the stove with pellets

When lighting for the first time,

see chapter 10.

- Power failure during stove

operation

The appliance will cool down and

then will carry out the lighting stage

automatically.

Pull

- Automatic burn pot cleaning

This message is not an alarm

This function is starting each 3 hours

and 20 minutes making the fumes motor

working at max power for 30 seconds in

order to keep the burn pot clean.

No Pell

Atte

Empty the burn pot and the restart the stove

again. Maybe you have to adjust the pellet

feeding after the running in of the gearmotor.

If the stove is new:

Fill the hopper with pellet.

Set the stove on position 3 or 4 for a min.

period of 30 hours for a good settlement of

the motors and of the mechanical compo-

nents. During these 30 hours, set the room

thermostat on

HOT.

When the stove turns off (normal turning

off or caused by an alarm) it is necessary

to wait its cooling down and provide to

clean the burn pot.

Only after these operations you can start

the stove again.

Type of problem

- Low temperature in the fire chamber,

the fire dies and the pellet feeding

stops.

- When the stove is trying another

starting after having just turned off

( normal turning off or caused by

an alarm)

Loading...

Loading...