4.1 Technical data of control unit

Operating voltage 230V AC +/-10%, 50/60 Hz

Relay contact 1 relays3

max. switching current x A AC1 - 250V AC11 10

x 1 A AC1 - 250V AC2 6

max. switching voltage 250V AC - 50..60 Hz

Display 4 13 mm LED-Display, digits

Display range -999 ... 9999

LED switching status displays 3 mm

Number of sensor inputs 1 or 2

Measurement range -5° ... +95°C

Temperature resolution 0.1°C

Sensor input KTY 81-210

Control mode two-step controller

Hysteresis* 0.1 K .. 99,9 K (standard adjusting 0.7 K)

Water detection via 2 independent level monitors

Target temperature T1* standard adjusting °C4

Target temperature T2* standard adjusting 4°C

Digital inputs 8 (via optocoupler)

Interface 2x RS 485

Connection Plug-in screw connections

for cables up to 2 5 mm².

Environment specifications:

- Operation temperature 0° .. +50°C

- Storage temperature -20° .. +70°C

- max. humidity 75% (no dew)

Technical data subject to change

Page 9

4. Technical Data

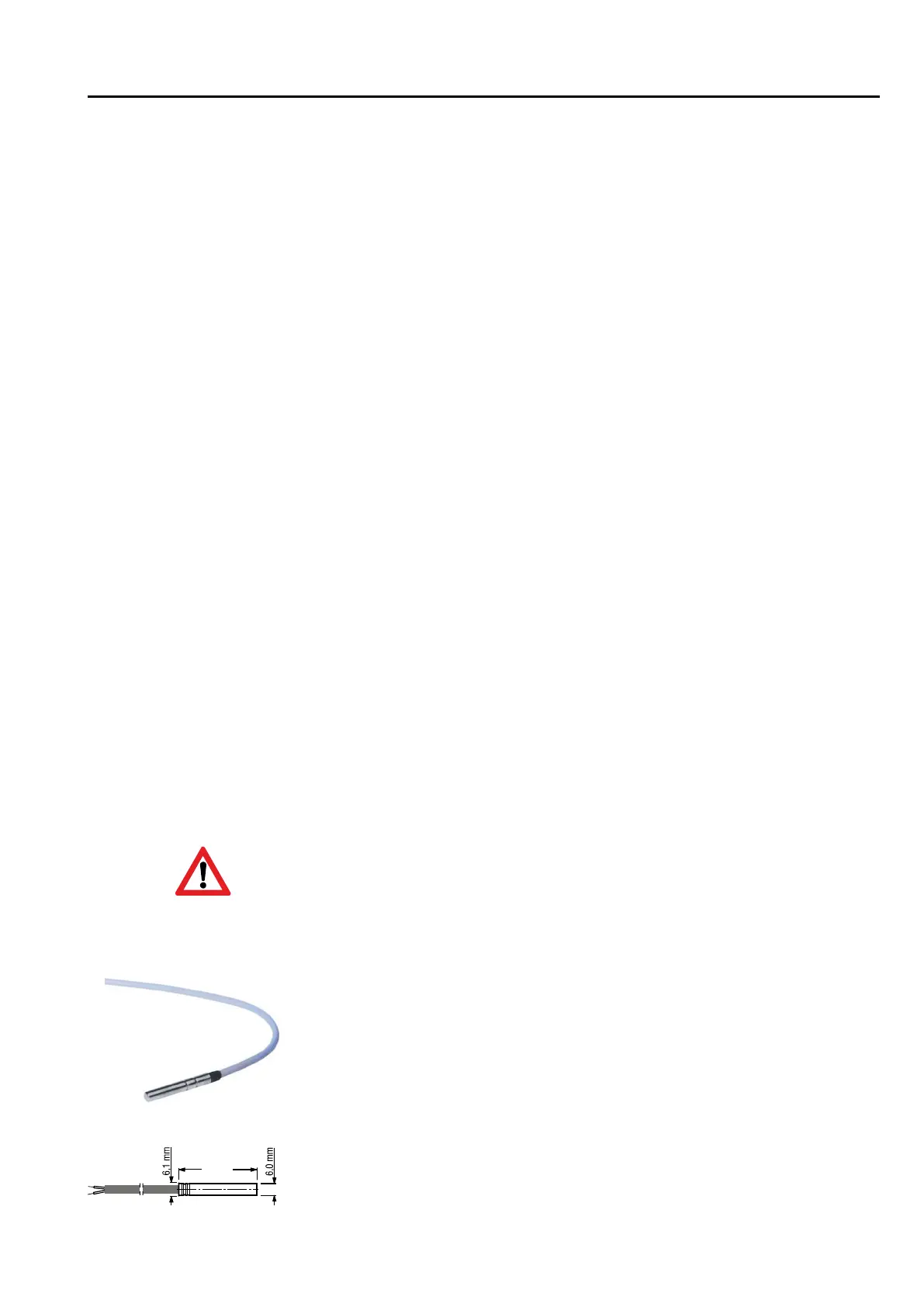

4.2 Fitting the sensor

When setting the temperature controller parameters (and whenever the sensor is

replaced) the “actual value correction” [Parameter C91] must be adjusted so that the

temperature measured corresponds to that shown on the display. A reference thermo-

meter should be used for this purpose.

Pay attention to the permitted temperture range for sensor cable exposure.

40 mm

The sensor cable must not be chafed or kinked.

There must be no substantial mechanical pressure on the sensor tube.

Do not place the sensor and the high-voltage cable in the same cable

conduit (not even within the switchbox).

Temperature range sensor cable -10°C .. +70°C

Changing the sensor cable length

lf it is necessary to shorten or lengthen the sensor cable on installation (or if a sensor

other than the one supplied is to be fitted), the "actual value correction" parameter

must be adjusted accordingly.

Loading...

Loading...