Drive modules

188

3.

DRIVE MODULES

Compact drives

168

DDS

HARDWARE

Ref.1310

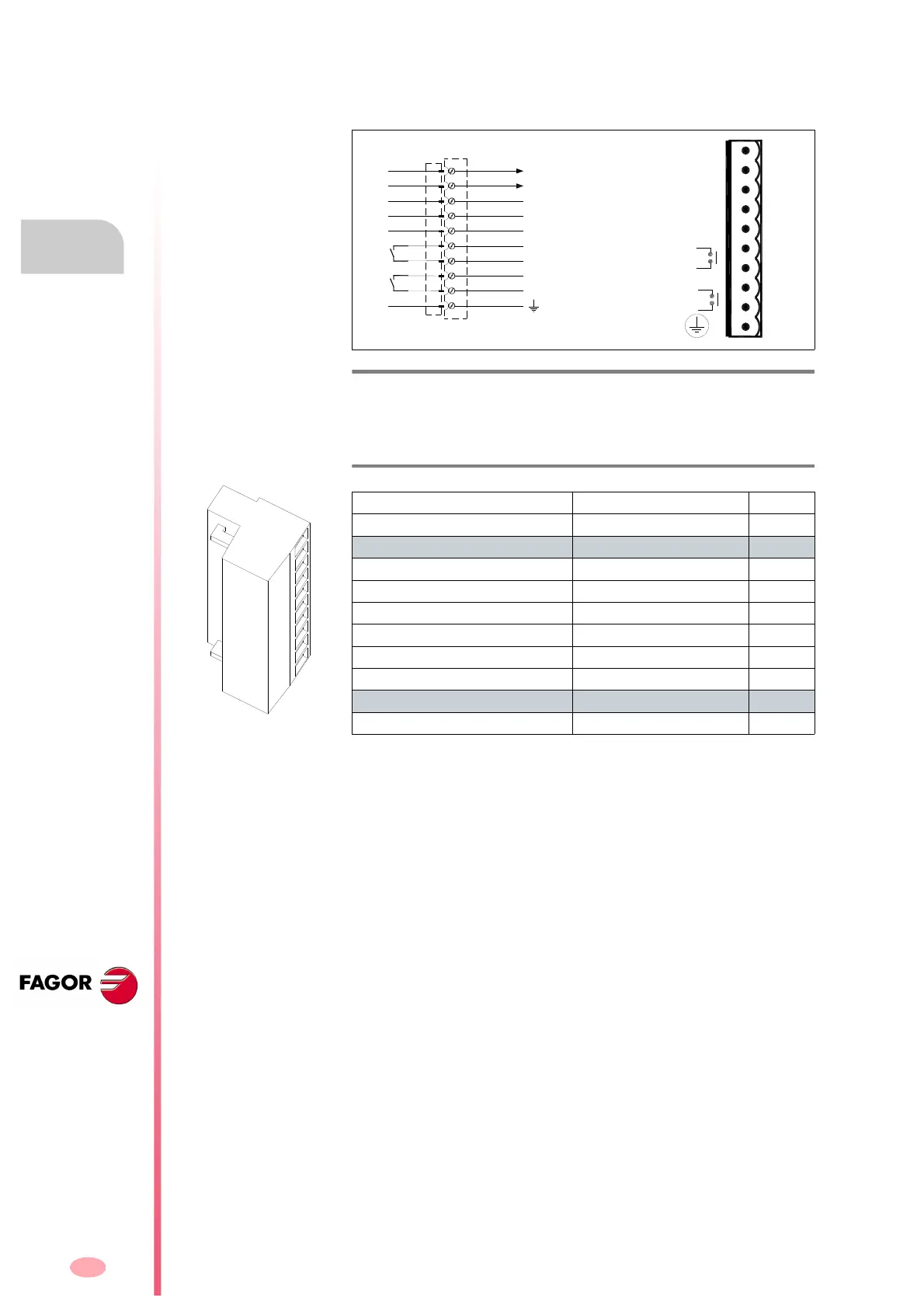

X2 connector

10-pin connector of the compact drive and integrates the functions of the

power supply and the modular drive.

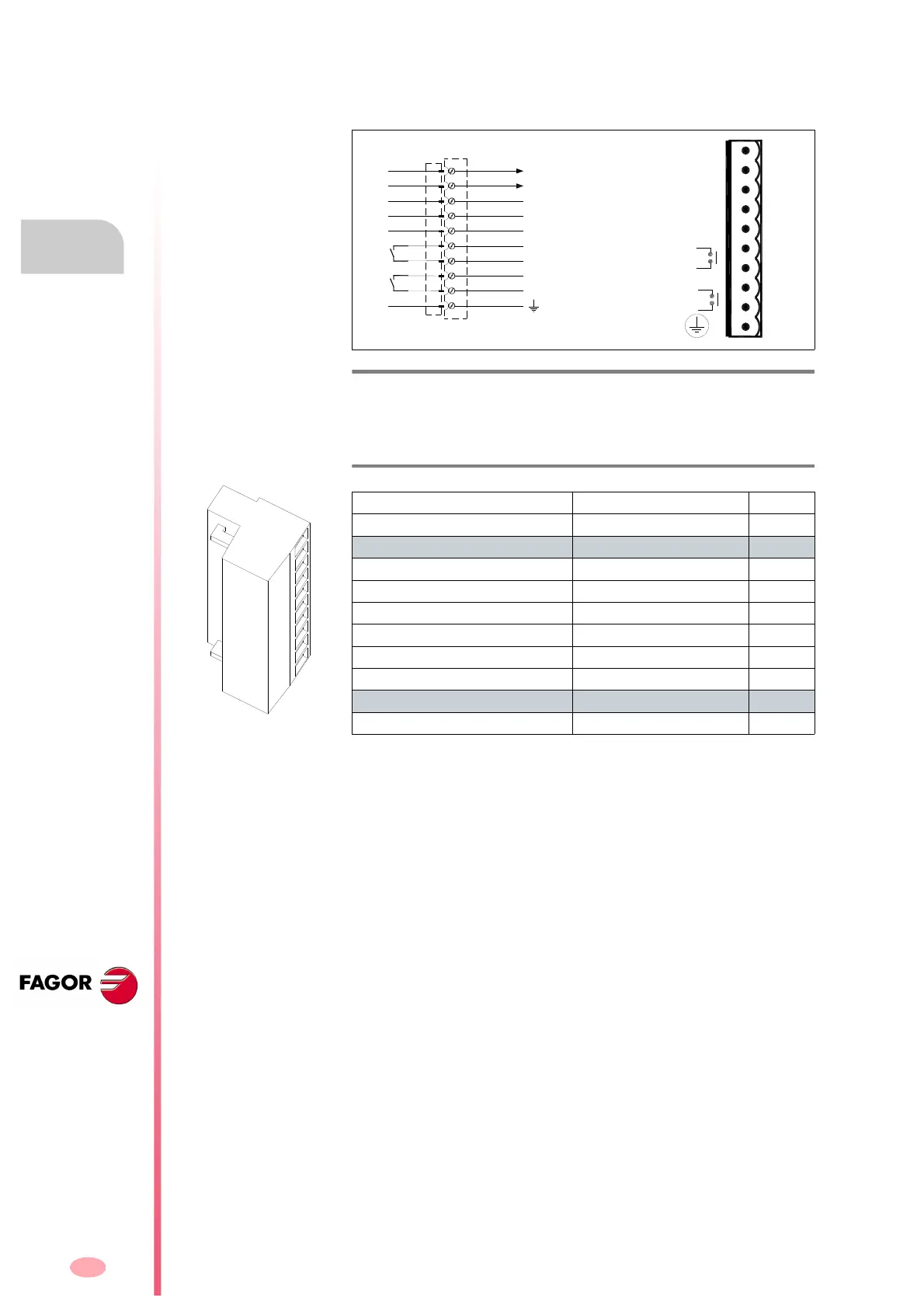

The following table shows the values for gap, tightening torque (wire en-

try holes) and other data regarding the screw-on terminals of the aerial

plug-in connector for X2 according to drive model:

Specific of the power supply

With the Error Reset input (pin 3), it possible to remove the errors at a

compact drive. See “resettable errors” of chapter 14 of the

“man_dds_soft.pdf” manual. Hence, activating this input (24 V DC) elimi-

nates the resettable errors.

If the cause of the error persists, the status display will show the same er-

ror again.

But if it is a major error, it can only be eliminated by powering the unit off

and back on.

Pins 1 and 2 offer a 24 V DC output for the user.

The maximum output current is 100 mA.

Specific functions of the modular drive

Control signals. With the “Drive Enable” and “Speed Enable” inputs (pins

4 and 5) together with the velocity command, it is possible to govern the

motor.

The consumption of these control signals is between 4.7 and 7 mA.

The following page describes the behavior of the drive depending on

these control signals.

The “Drive Ok” contact (pins 6 and 7) will stay closed as long as the com-

pact drive runs properly.

F. H3/118

Connector X2. Control.

T. H3/23 Technical data of the aerial plug-in connector for X2.

ACD/SCD/CMC SCD

1.08/1.15/1.25/2.35/2.50 2.75

Connector data

Nr of poles 10 10

Gap (mm) 5.00 5.00

Min/max tightening torque (Nm) 0.5/0.6 0.5/0.6

Screw thread M3 M3

Min./max. section (mm²) 0.2/2.5 0.2/2.5

Rated current In

(A) 12 12

Wire data

Length to strip (mm) 7 7

RESET

ERROR

+24VDC

OV.

O.K.

PROG.

ENABLE

SPEED

ENABLE

DR.

DRIVE

OUT

OP5 [F01411]

PROG OUT

DRIVE OK

SPEED ENABLE

DRIVE ENABLE

ERROR RESET

0 VDC

+24 VDC

1

2

3

4

5

6

7

8

9

10

Loading...

Loading...