DGP(L)−...−B

Festo DGP(L)−...−B 0609g English

35

9Care and maintenance

Maintaining the band system:

S Clean the band system if required with a soft cloth.

Cleaning agents: all non−abrasive media.

S Lubricate the surface of the band system if it no longer has a layer of grease.

Grease type: LUB−KC1 (silicon−free) from Festo.

Lubricating the roller bearing of types DGPL−...:

1. Make sure that the lubrication

intervals in accordance with Fig.32 are

observed. If the device is not operated frequently, lubrication should take

place at the latest after 3 years.

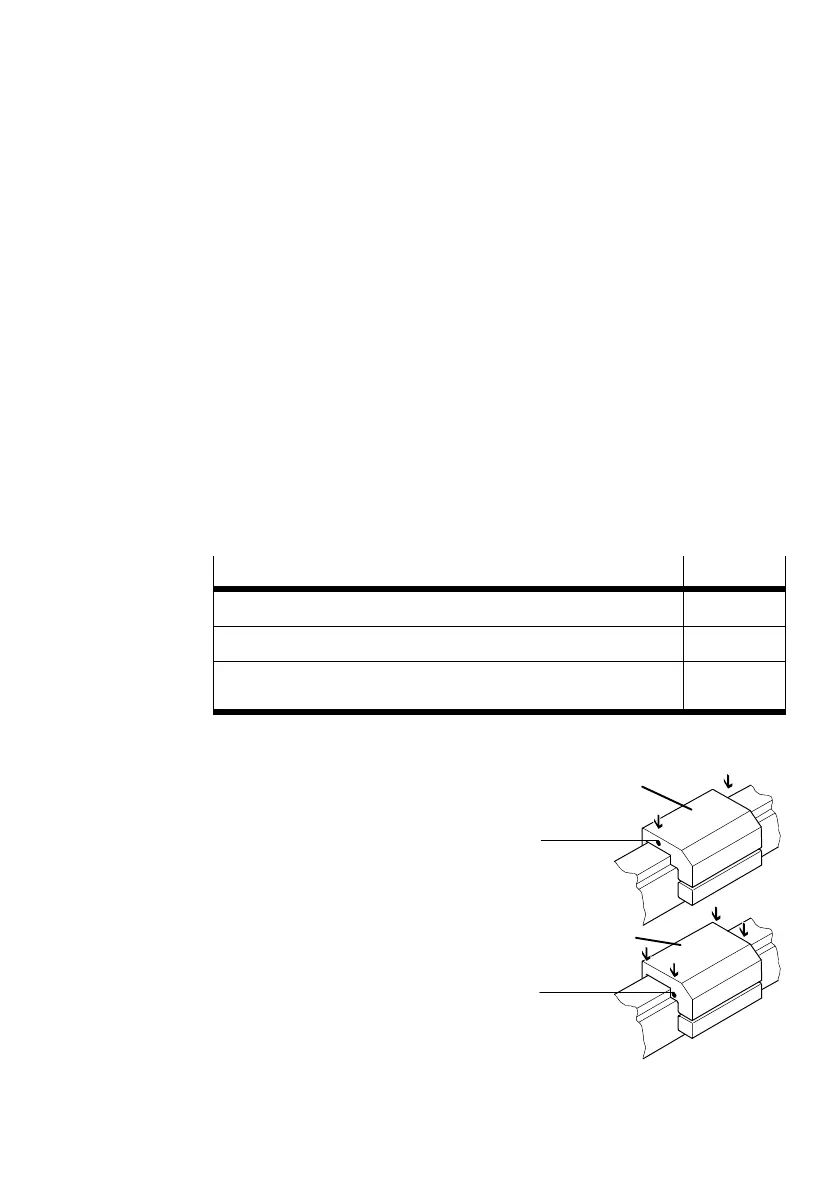

Lubrication intervals and grease types

The first lubrication 5000 km

The following interval with special grease LUB−KC1 (free of silicone) 400 km

Or:

The following interval with special grease LUB−RN2 (free of silicone)

5000 km

Fig.32

S Note that lubrication must be undertaken more often:

in dusty and dirty environments

with work strokes of < 50 mm

at speeds of > 2 m/s.

2. Exhaust the DGPL−....

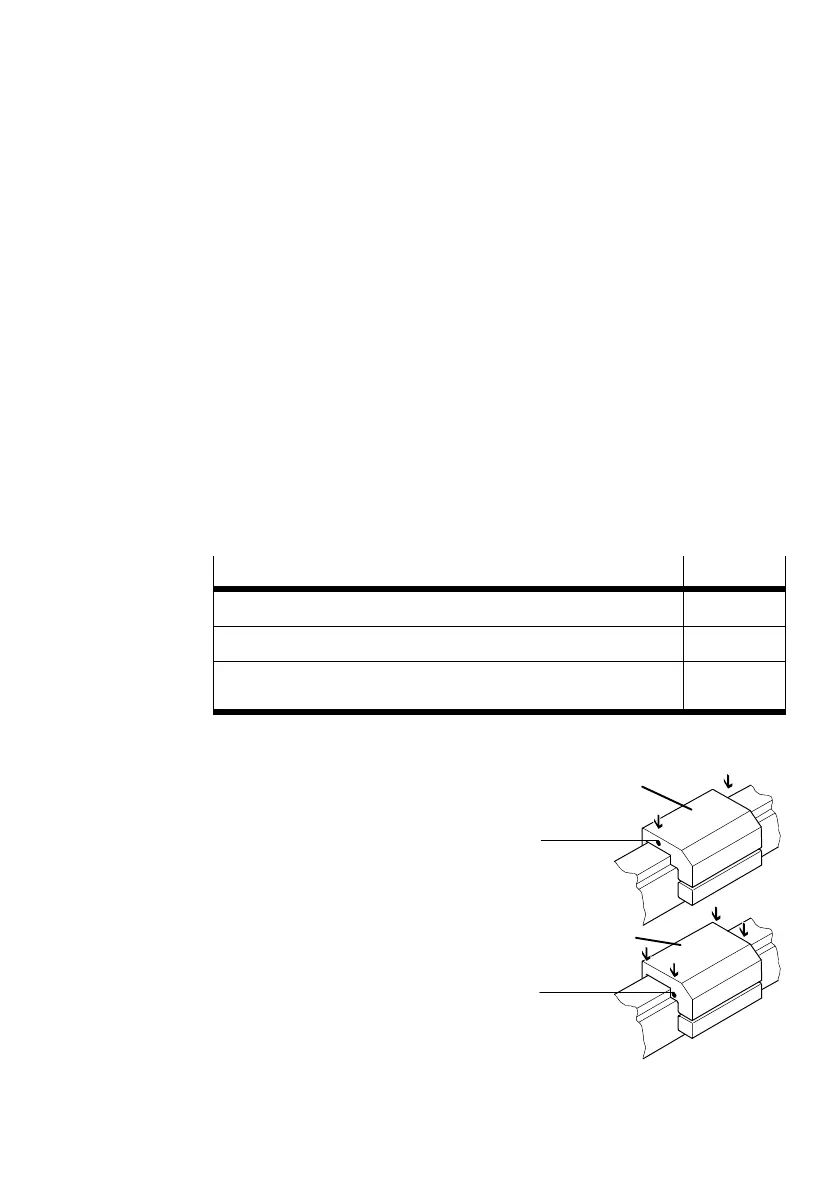

3. Lubricate the slide bearings at all

lubricating nipples aJ.

Special grease and grease gun with

pin−point nozzle as per "Accessories".

S Move the slide over the

complete posi

tioning path during lubrication in order

to distribute the grease equally inside

the device.

4. Lubricate the surface of the band system if it no longer has a layer of grease

(grease type: see Fig.32).

Fig.33

DGPL−18−KF

DGPL−...−KF

aJ

aJ

Loading...

Loading...