24

CLEANING AND MAINTENANCE (CONTINUED)

SEASONAL AND WINTER STORAGE MAINTENANCE

1. Drain slurry tank of all water, prior to storage, and remove all drain plugs.

2. Park unit in suitable location and chock wheels to prevent inadvertent movement.

3. If possible, cover machine with tarp or park inside of an enclosure.

4. Store HydroSeeder

®

with all slurry valve handles in the open position. To prevent damage

from freezing, it is advisable to remove all slurry valves and store in a heated area.

5. Pour 1 qt (0.95 L) of mineral oil or environmentally safe lubricant into pump housing and

spin pump by hand to prevent rust in pump. Remove drain plug.

6. Chip and steel-brush any interior rust spots in the slurry tank and touchup with paint. See

numbers 2 and 3 in IV. Maintenance of the HYDROSEEDER

®

Safety Summary Section.

7. Lubricate all fittings.

8. Change hydraulic oil and filter. (400 hours)

9. Disconnect battery cables. In cold weather, remove battery and store it in a safe, warm

place.

10. Add fuel stabilizer to fuel tank.

NOTE: Make sure to lubricate equipment after it has been removed from storage

and before it is put back into operation. This will ensure that everything

has a fresh coating of grease.

HYDRAULIC SYSTEM

The hydraulic system on your FINN HydroSeeder

®

is designed to give trouble-free service, when

properly maintained. The most important areas of maintenance are the hydraulic oil and filtration.

The reservoir holds 8 gallons (30 L) of hydraulic oil. The hydraulic oil should be replaced per the

lubrication schedule or if the oil becomes milky or gives off a burnt odor. The hydraulic oil filter

must be replaced on schedule with a 5 absolute micron filter (FINN part number 023914). The

hydraulic system relief is factory-set at 2,300 psi (15,858 kPa).

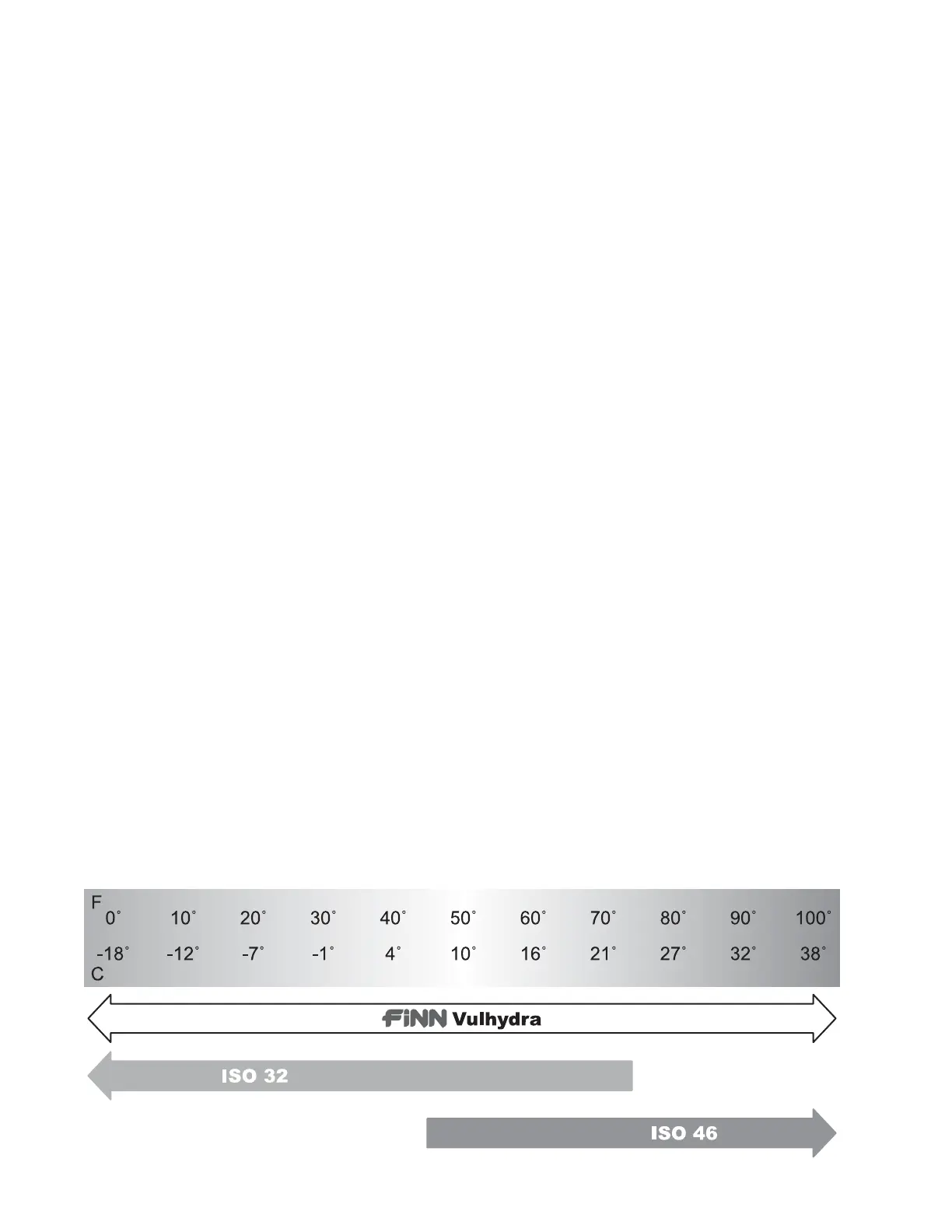

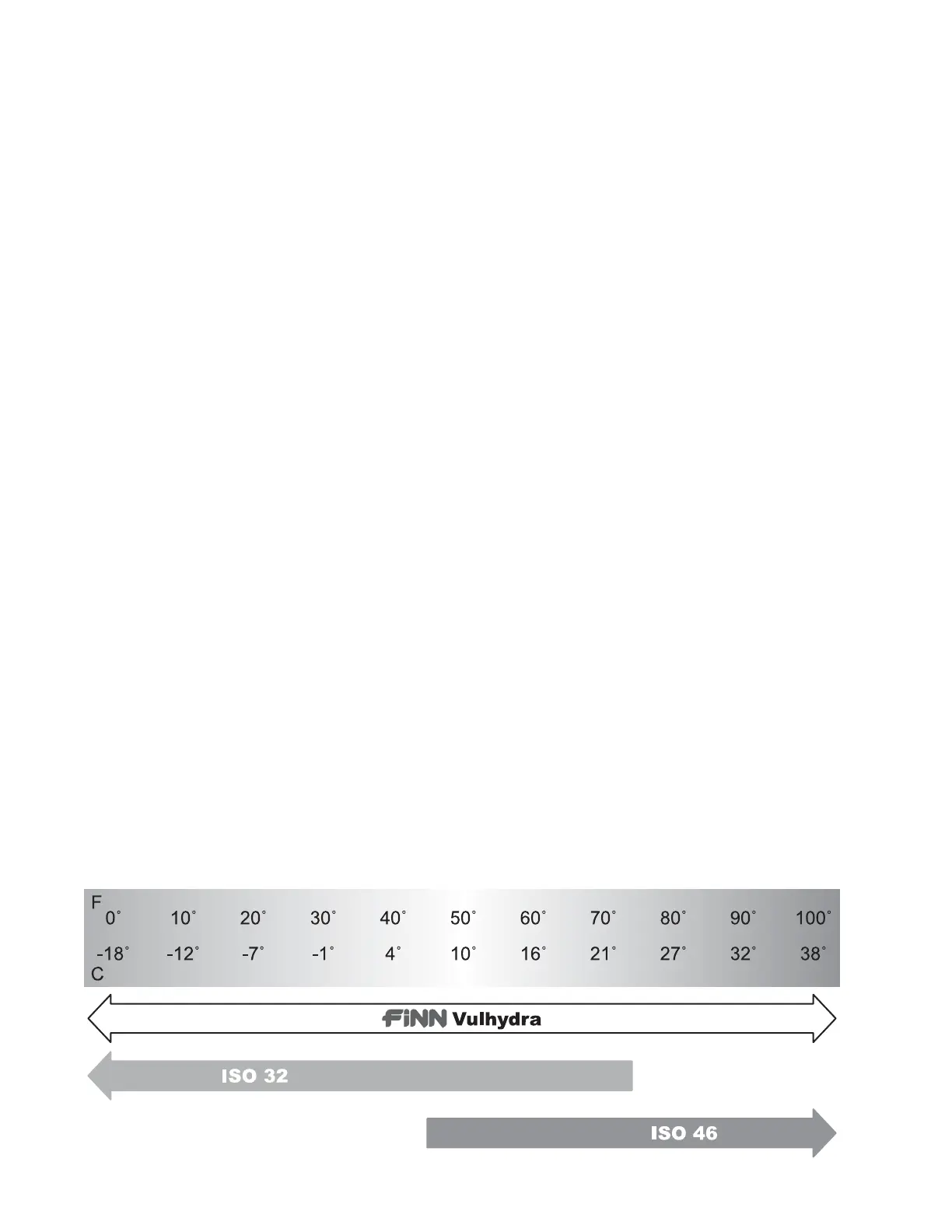

At time of manufacture, this unit contains Finn Vulhydra hydraulic oil. The chart below illustrates

the operating temperature range of the Finn Vulhydra hydraulic oil as well as the closest ISO

equivalents.

NOTE: The Finn Vulhydra hydraulic oil may be substituted for either of the two

ISO oils listed below. Please use the temperature chart to determine what

oil works best in your situation.

Loading...

Loading...