MAINTENANCE

Engine Service and Repair

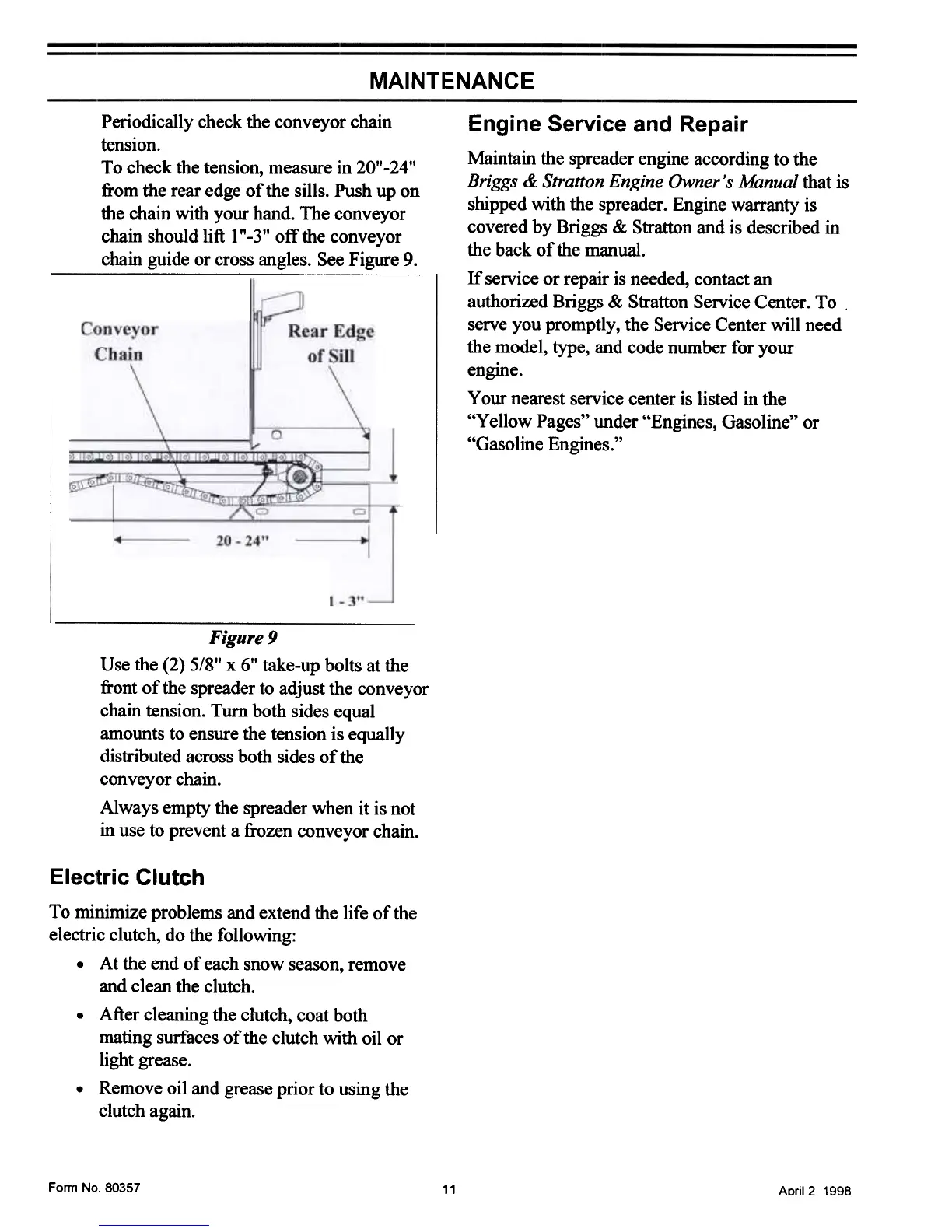

Periodically check the conveyor chain

tension.

To check the tension, measure in 20"-24"

from the rear edge of the sills. Push up on

the chain with your hand. The conveyor

chain should lift 1 "-3" off the conveyor

chain guide or cross angles. See Figure 9.

Maintain the spreader engine according to the

Briggs & Stratton Engine Owner's Manual that is

shipped with the spreader. Engine warranty is

covered by Briggs & Stratton and is described in

the back of the manual.

If service or repair is needed, contact an

authorized Briggs & Stratton Service Center. To

serve you promptly, the Service Center will need

the model, type, and code number for your

engIne.

Your nearest service center is listed in the

"Yellow Pages" under "Engines, Gasoline" or

"Gasoline Engines."

Figure 9

Use the (2) 5/8" x 6" take-up bolts at the

front of the spreader to adjust the conveyor

chain tension. Turn both sides equal

amounts to ensure the tension is equally

distributed across both sides of the

conveyor chain.

Always empty the spreader when it is not

in use to prevent a frozen conveyor chain.

Electric Clutch

To minimize problems and extend the life of the

electric clutch, do the following:

.At the end of each snow season, remove

and clean the clutch.

.After cleaning the clutch, coat both

mating surfaces of the clutch with oil or

light grease-

.Remove oil and grease prior to using the

clutch again.

Form No.80357

11

ADril 2. 1998

Loading...

Loading...