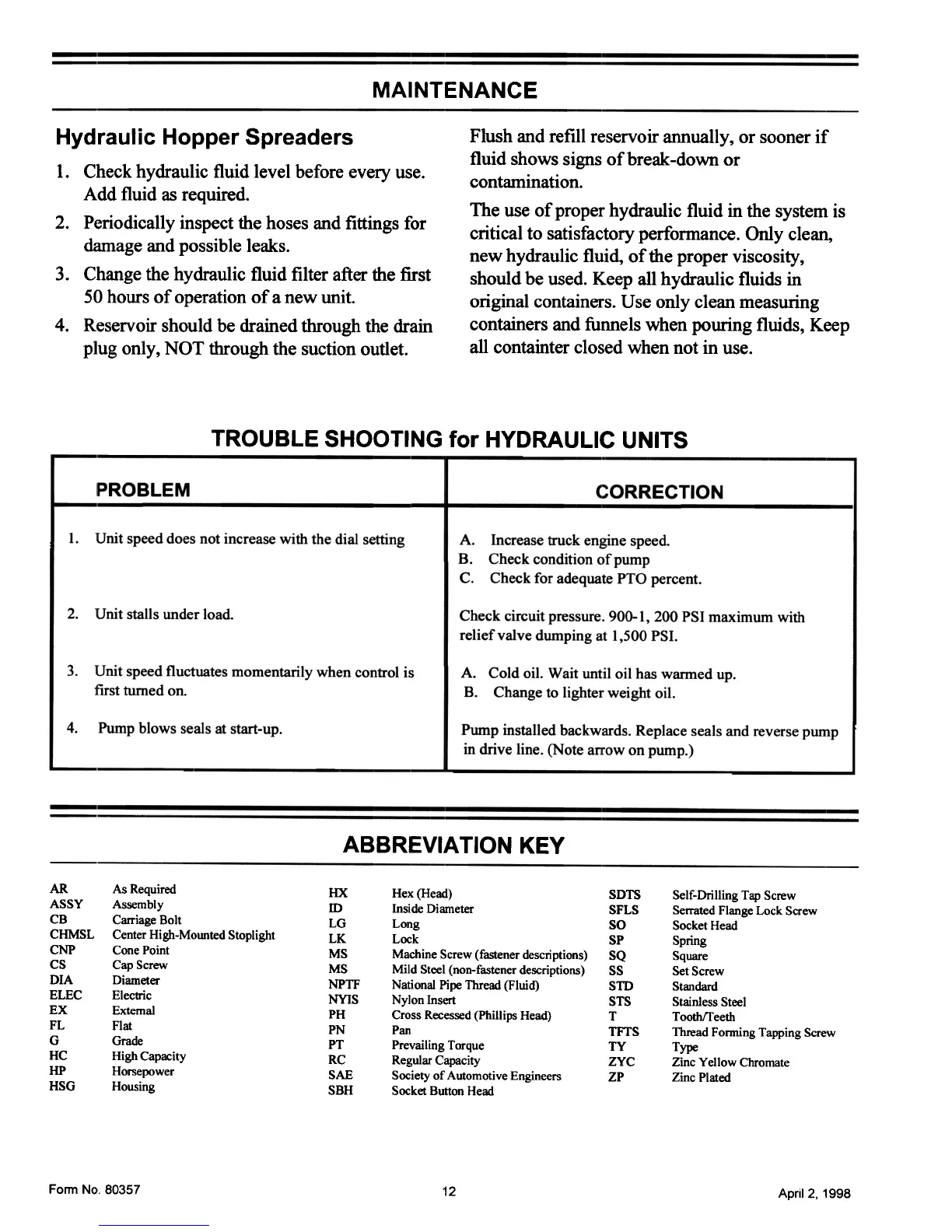

MAINTENANCE

Flush and refill reservoir annually, or sooner if

fluid shows signs of break-down or

contamination.

The use of proper hydraulic fluid in the system is

critical to satisfactory performance. Only clean,

new hydraulic fluid, of the proper viscosity,

should be used. Keep all hydraulic fluids in

original containers. Use only clean measuring

containers and funnels when pouring fluids, Keep

all containter closed when not in use.

Hydraulic Hopper Spreaders

I. Check hydraulic fluid level before every use.

Add fluid as required.

2. Periodically inspect the hoses and fittings for

danlage and possible leaks.

3. Change the hydraulic fluid filter after the first

50 hours of operation of a new unit.

4. Reservoir should be drained through the drain

plug only, NOT through the suction outlet.

TROUBLE SHOOTING for HYDRAULIC UNITS

iPROBLEM

CORRECTION

I, Unit speed does not increase with the dial setting

A. Increase truck engine speed.

B. Check condition of pump

C. Check for adequate PTO percent.

2.

Unit stalls under load

Check circuit pressure. 900-1, 200 PSI maximum with

relief valve dumping at 1,500 PSI.

3. Unit speed fluctuates momentarily when control is

fIrst turned on.

A. Cold oil. Wait until oil has warmed up.

B. Change to lighter weight oil.

4.

Pump blows seals at start-up.

Pump installed backwards. Replace seals and reverse pump

in drive line. (Note arrow on pump.)

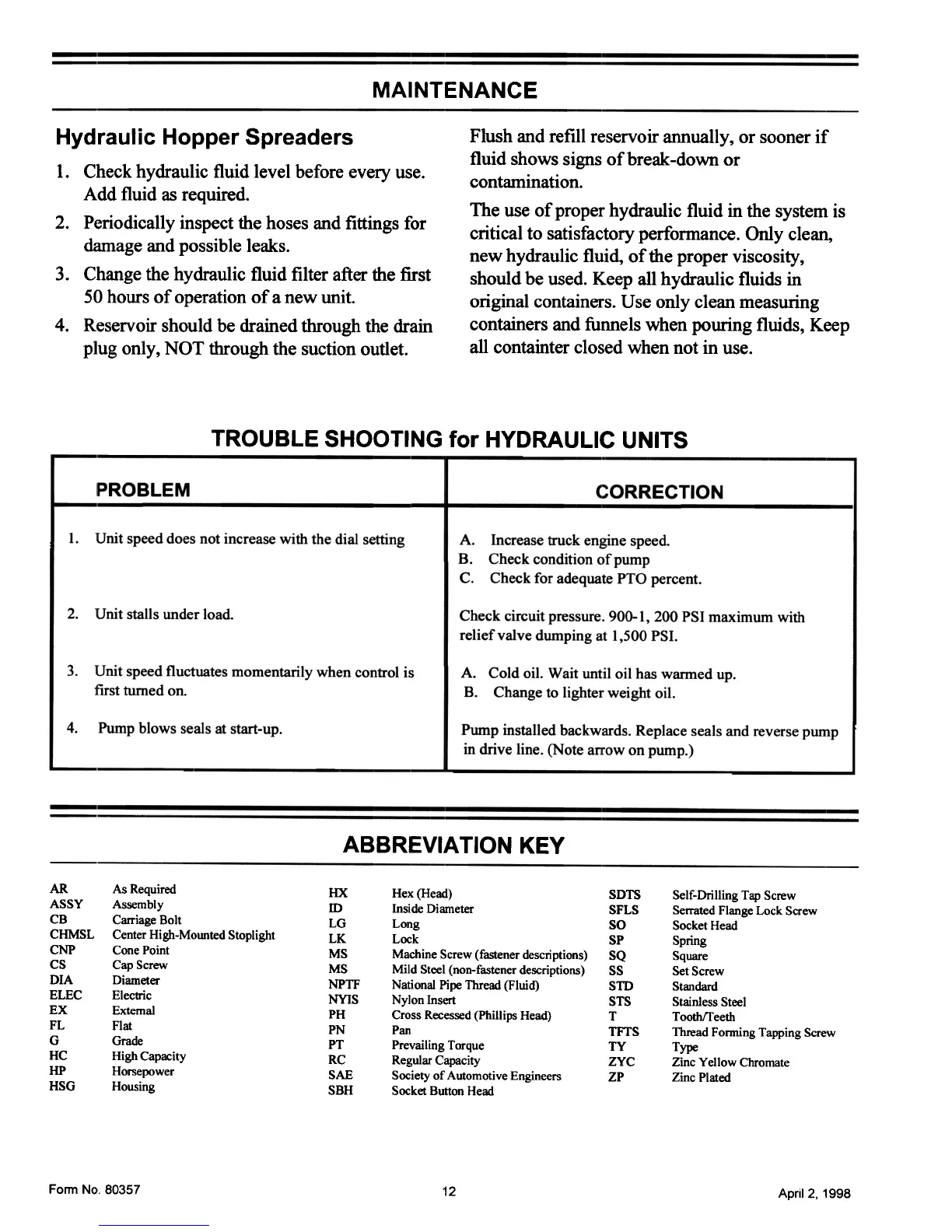

ABBREVIA TION KEY

AR

ASSY

CB

CHMSL

CNP

CS

DIA

ELEC

EX

FL

G

HC

HP

HSG

HX

ill

LO

LK

MS

MS

NPTF

NYIS

PH

PN

PT

RC

SAE

SBH

SDTS

SFLS

SO

SP

SQ

SS

sm

STS

T

TFTS

TV

ZVC

ZP

As Required

Assembly

Carriage Bolt

Center High-Mounted Stoplight

Cooe Point

Cap Screw

Diameter

Electric

Extemal

Flat

Grade

High Capacity

Horsepower

Housing

Self-Drilling Tap Screw

Serrated Flange Lock Screw

Socket Head

Spring

Square

Set Screw

Standard

Stainless Steel

Tootb/feeth

Thread Forming Tapping Screw

Type

Zinc Yellow Chromate

Zinc Plated

Hex (Head)

Inside Diameter

Long

Lock

Machine Screw (fastener descriptions)

Mild Steel (non-fastener descriptions)

National Pipe Thread (Fluid)

Nylon Insert

Cross Recessed (Phillips Head)

Pan

Prevailing Torque

Regular Capacity

Society of Automotive Engineers

Socket Button Head

Form No.80357

12

April 2, 1998

Loading...

Loading...