Manual Flamcomat MK-U G4

We reserve the right to change designs and technical specifications of our products.

13

ENG

5.2 Connectivity options

Connectivity options Designated use

Ethernet port To connect Flamcomat to a Building Management System (BMS) via modbus or bacnet.

Standard USB (aka USB-A) For saving the o line log and the configuration parameters. The second option for this port is to update the firmware of the

controller (to download a new control SW)

CAN This pair of the ports is dedicated for the networking of multiple Flamcomats

RS-485 The primary designation is to connect Flamcomat to Internet (via Gateway and HFC protocol). Alternatively – BMS via Modbus

Alternatively – BMS via bacnet (only one out of three options at the same time)

Wireless To connect a smartphone application

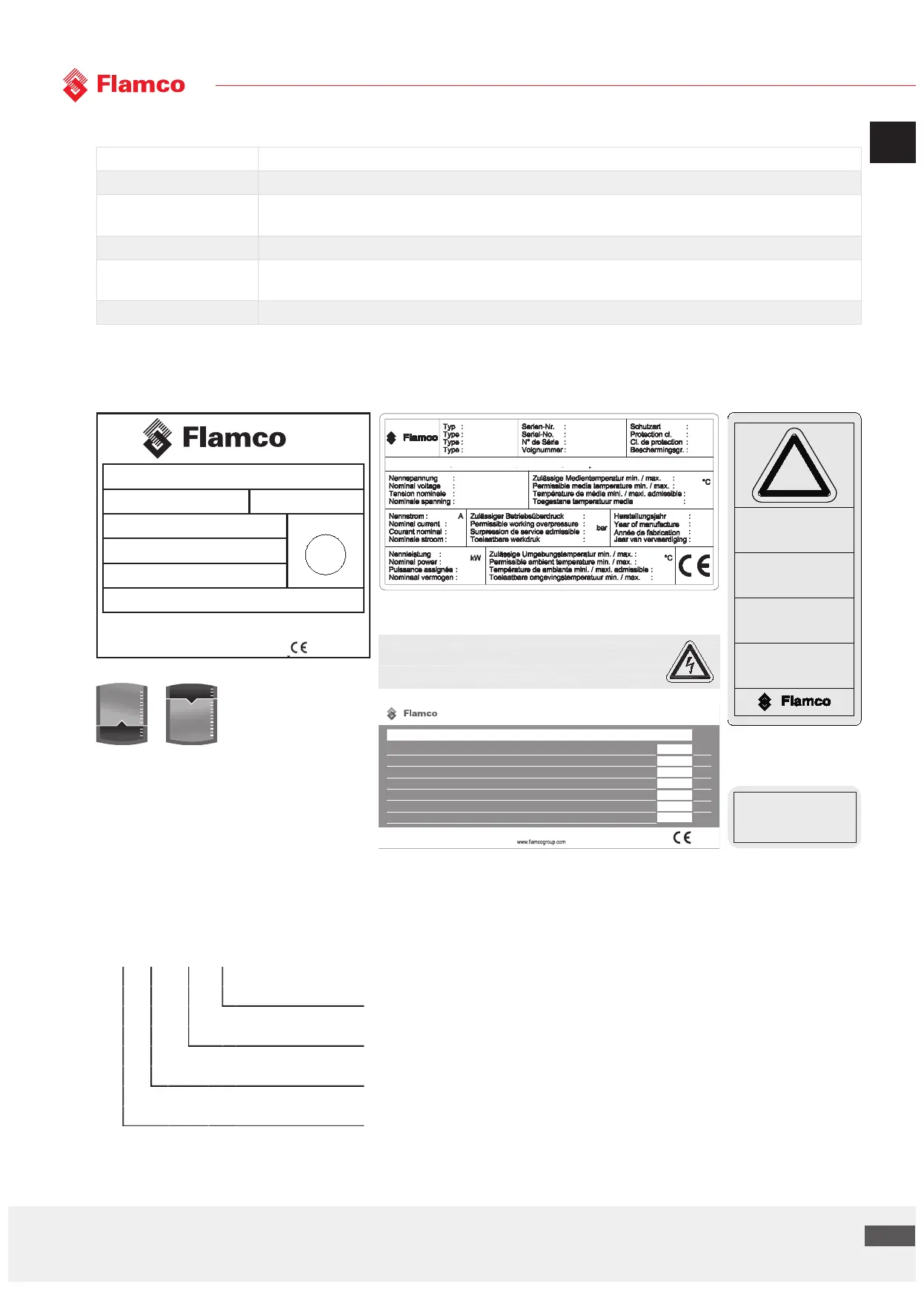

5.3 Markings

Name plate - Vessel: Name plate - Compressor module:

Service:

Transport lock:

Electrical warnings:

1000 Ltr

1000 Ltr

≤

high voltage! Opening by qualified personnel only.

gefährliche Spannung! Nur vom Fachpersonal zu öffnen.

Disconnect the unit from the power supply before opening it.

Vor dem Öffnen des Gerätes spannungsfrei schalten.

At t ent ion,

Ac ht un g,

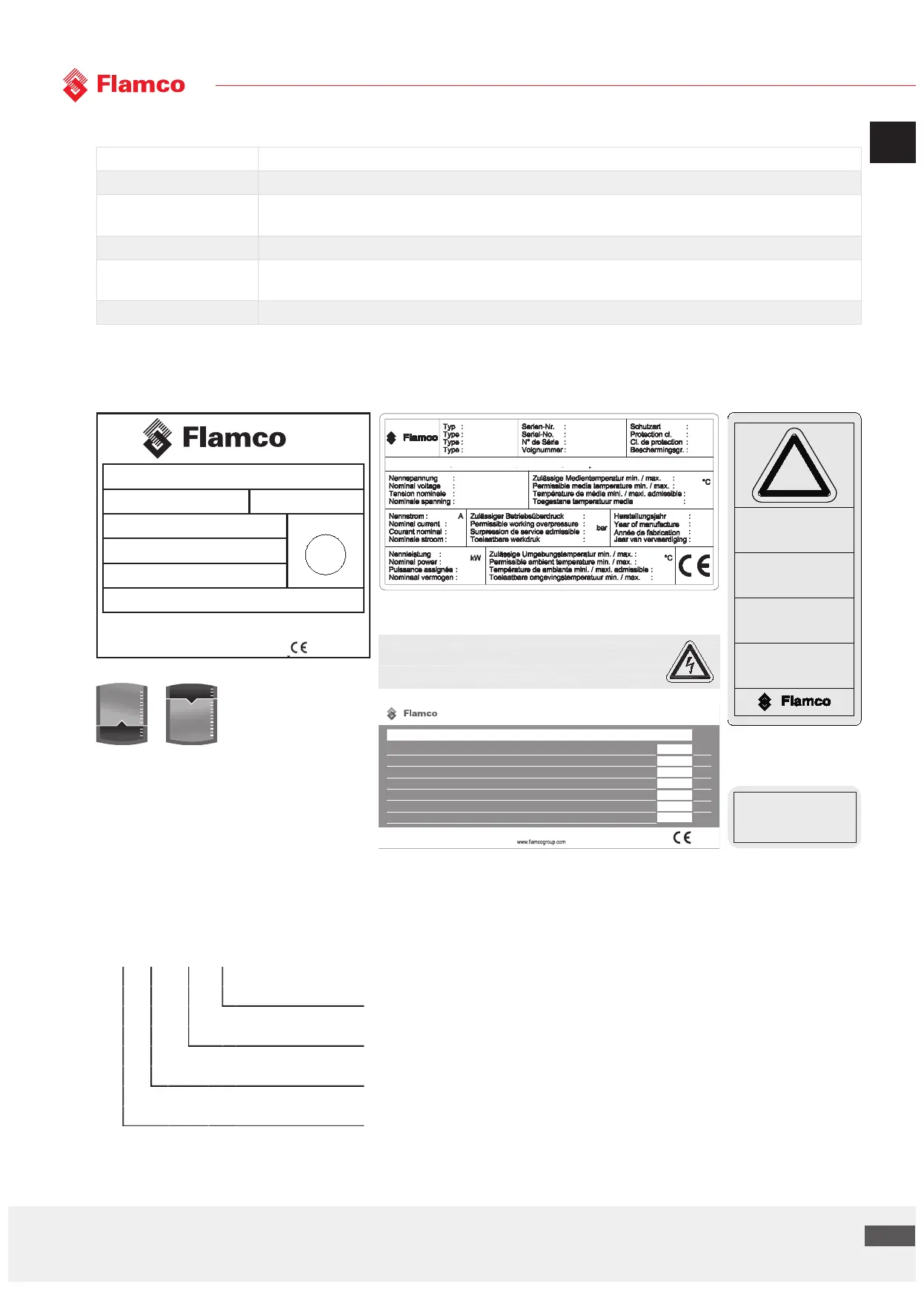

Capacity / Inhalt / Inhoud / Contenance

Gas charge / Vordruck / Voordruk / Pression initiale

Max. working pressure / Max. zul. Betriebsüberdruck / Max. werkdruk / Pression de service max.

Test pressure / Prüfdruck / Testdruk / Pression d’épreuve

Max. temp. diaphragm / Max. Betriebstemp. Membrane / Max. temp. membraan / Temp. membrane max.

Min. working temperature / Min. Betriebstemperatur / Min. werktemperatuur / Température de service min.

Article code / Artikelnummer / Artikelnummer / Code article

litres

bar

bar

bar

°C

°C

Your reliable partner

Flamco B.V. - Bunschoten - the Netherlands

!

Nach Montage:

Transportsicherung

entfernen.

After mounting:

Remove the transport

safety.

Après I'installation:

Retirez la sécurité des

transports.

Na montage:

Verwijder de veiligheid

van het vervoer.

Service Nederland

Tel.: +31(0)33 299 7500

Fax.: +31(0)33 298 6445

Service Germany

Tel.: +49(0)170 630 40 34

Flamco B.V. - Amersfoortseweg 9 - 3751 LJ Bunschoten - the Netherlands

Type

Température de service mini. / maxi. admissible

Surpression de service admissible

Surpression d` essai

Capacité nominale

N° de série

litres

bar

bar

Type

Typ

Serial-No.

Serien-Nr.

Nominal volume

Nenninhalt

Permissible working overpressure

Zulässiger Betriebsüberdruck

Test overpressure

Prüfüberdruck

Permissible working temperature min. / max.

Zulässige Betriebstemperatur min. / max.

litre

Liter

0045

Constructeur: Flamco STAG GmbH

Manufacturer: D-39307 Genthin

Hersteller: GERMANY

°C

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

Année de fabrication

Year of manufacture

Herstellungsjahr

:

:

:

M

a

n

u

f

a

c

t

u

r

e

r

´

s

m

a

r

k

i

n

g

H

e

r

s

t

e

l

l

e

r

k

e

n

n

z

e

i

c

h

e

n

M

a

r

q

u

e

d

i

s

t

i

n

c

t

i

v

e

d

u

c

o

n

s

t

r

u

c

t

e

u

r

5.4 Type key compressor control unit

Remark: keying is hardware specific, so ware is article number specific

Nom. frequency of the operating voltage (Hz): 50 = 50 Hz; 60 =

60 Hz

Compressor manufacturer: 1; 2

Compressor class: 11 = K11; 31 = K31; 40 = K40

version: MK = Monocompressor; DK=Duocompr.

E.g.: MK11 – 1 -50

Loading...

Loading...