Manual Flamcomat MK-U G4

We reserve the right to change designs and technical specifications of our products.

28

ENG

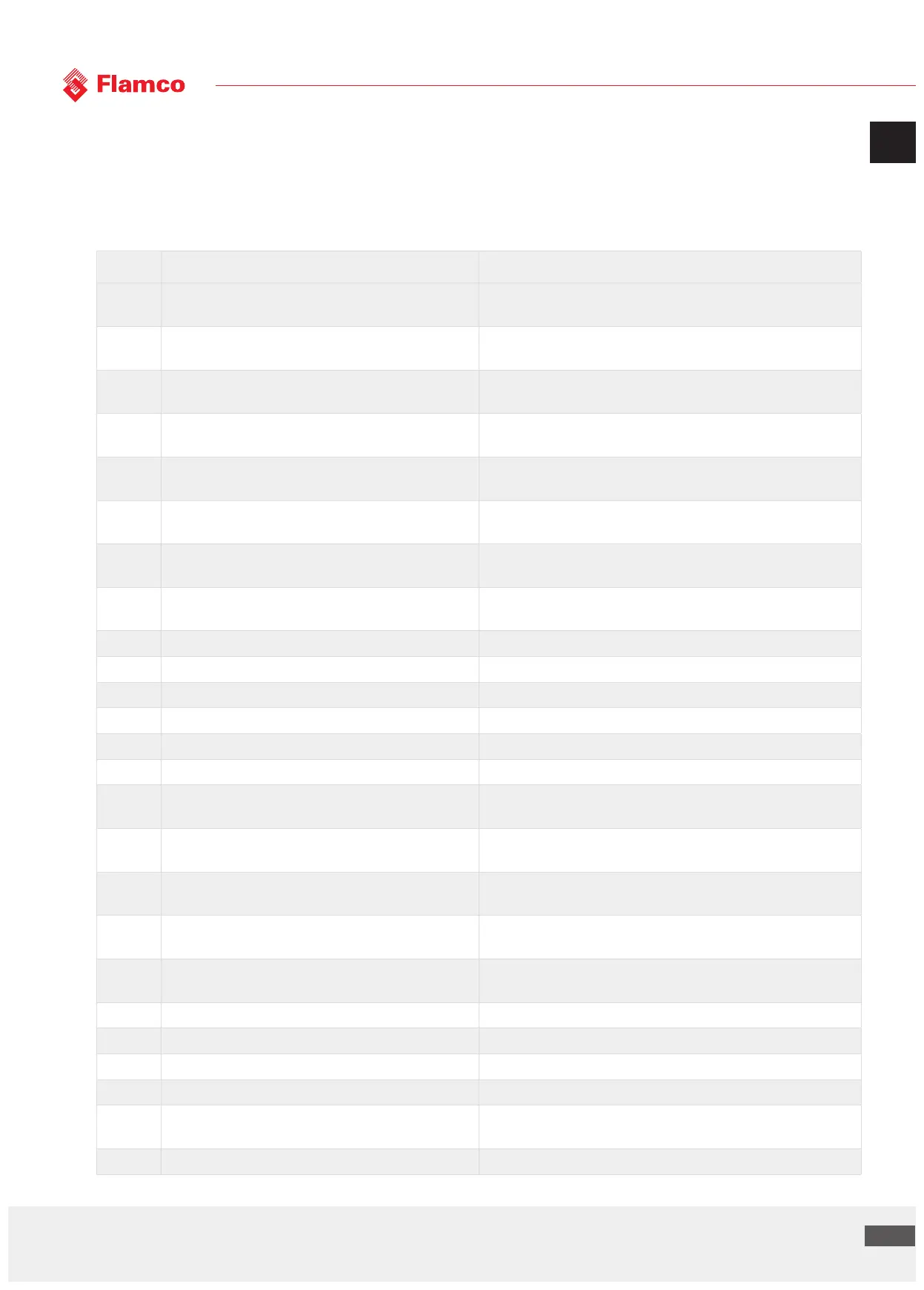

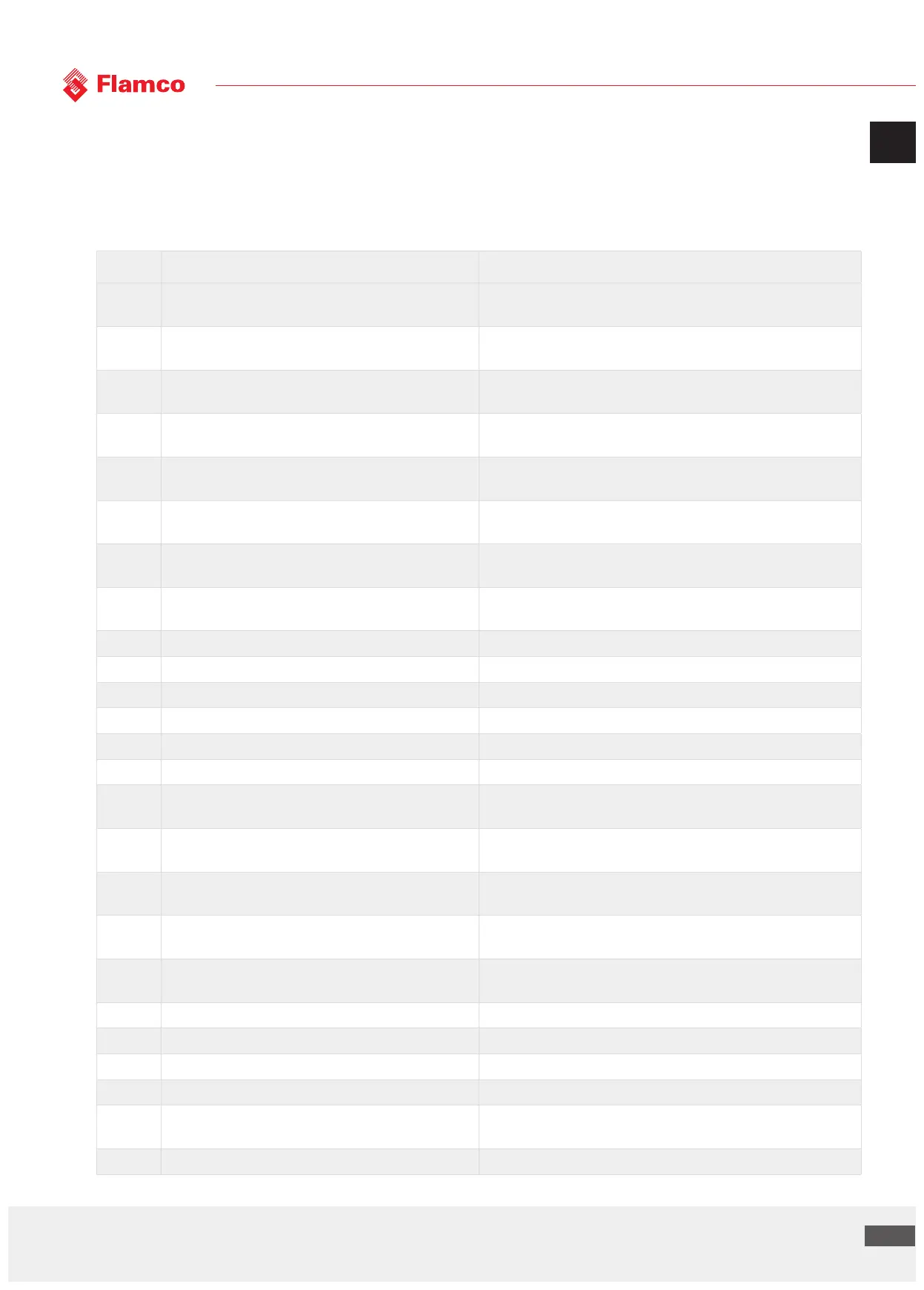

7.5 Malfunction messages

Procedures and values for error identification, evaluation and output have been tried in practice, prevent secondary failures

and invite user awareness. Please note that incorrect set-up conditions can lead to repeated errors and inhibit the intended

use. Examples of incorrect set-up conditions are: incorrect or no longer applicable design, outdated equipment, incorrect

installation and inadmissible operational parameters

Error #

GUI Action

0

Single compressor maximum run time error Compressor failure. Check functioning of compressor. Call Technical support if

no solution can be found.

1

Redundant compressors maximum run time error Compressor failure. Check functioning of compressor. Call Technical support if

no solution can be found.

2

Load dependant compressors maximum run time error Compressor failure. Check functioning of compressor. Call Technical support if

no solution can be found.

3

Single compressor current error Potential failure of compressor. Check electrical connection of compressor. Call

Technical support if no solution can be found.

4

Compressor A current error (double compressor configuration) Potential failure of compressor. Check electrical connection of compressor. Call

Technical support if no solution can be found.

5

Compressor B current error (double compressor configuration) Potential failure of compressor. Check electrical connection of compressor. Call

Technical support if no solution can be found.

6

Compressors A and B current error (double compressor

configuration)

Potential failure of compressor. Check electrical connection of compressor. Call

Technical support if no solution can be found.

7

Compressor C current error Potential failure of compressor. Check electrical connection of compressor. Call

Technical support if no solution can be found.

8

Self-learning valve correction error Please reset the error by acknowledging the error in current error/warnings

9

Self-learning compressor correction error Please reset the error by acknowledging the error in current error/warnings

10

Pressure sensor current exceeded Check if the cable to the pressure sensor is not damaged

11

Pressure sensor no current Check if the cable to the pressure sensor is connected

12

Load cell current exceeded Check if the cable to the level sensor is not damaged

13

Load cell no current Check if the cable to the level sensor is connected

14

Compressor A power consumption too high Potential failure of compressor. Check electrical connection of compressor. Call

Technical support if no solution can be found.

15

Compressor B power consumption too high Potential failure of compressor. Check electrical connection of compressor. Call

Technical support if no solution can be found

16

Compressor C power consumption too high Potential failure of compressor. Check electrical connection of compressor. Call

Technical support if no solution can be found

17

Maximum run time M1 exceeded The compressor runs too long. Please make sure there is no leakage in the

system

18

Maximum run time M2 exceeded The compressor runs too long. Please make sure there is no leakage in the

system

19

Maximum suppletion threaded water amount exceeded Please replace a filter

20

Compressor running, no decrease of water level in vessel Potential failure of compressor(s) or clogged tube

21

Valve open, no increase of water level in vessel Potential failure of valve(s) or clogged tube

26

System run in auto mode You have le the manual mode. Automat maintains the pressure

29

Manual mode active, press V to start automat Acknowledge this message to run the automat in the AUTO mode (to leave the

MANUAL mode)

30

Diaphragm rupture The membrane is ruptured and should be replaced

Loading...

Loading...