Manual Flamcomat MK-U G4

We reserve the right to change designs and technical specifications of our products.

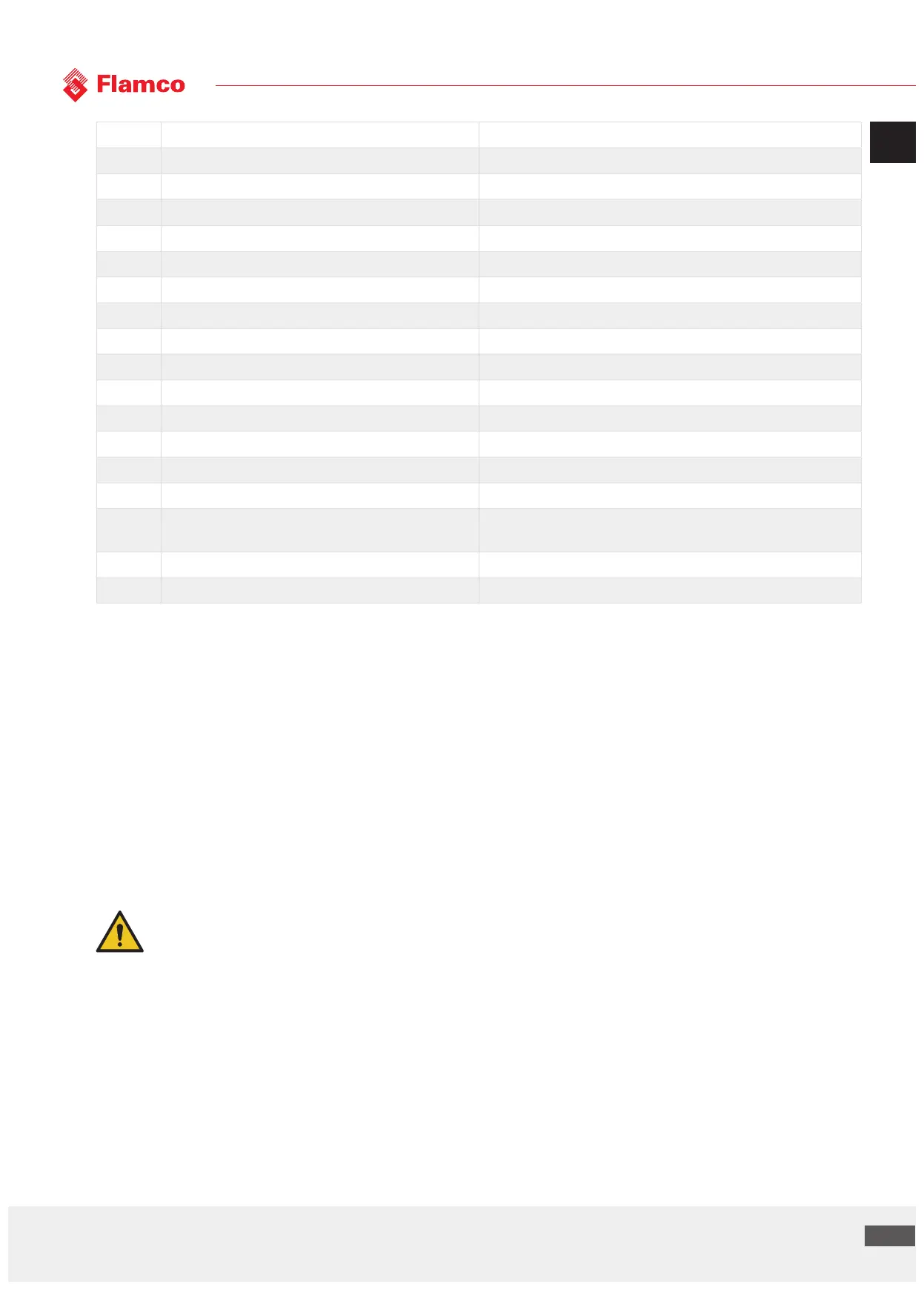

29

ENG

32

Water level increase in vessel without Flexcon activity Potential failure of manifold-, refill- or check valve

33

Water level decrease in vessel without Flexcon activity Potential leakage of vessel or connection sets

34

Maintenance 1 is due Carry out maintenance 1 (equipment service, every year)

35

Initial fill failed Potential failure of refill valve or clogged supply tube

36

Maximum refill time exceeded Potential failure of refill valve

38

No refill flow Please make sure the litre counter is available

39

Amount refill water too much System requires to much refill. Potential leakage

43

Initial fill active The automat fills a vessel with minimum amount of water

44

Manual initial fill active Fill in a vessel with minimum amount of water

47

Maintenance 2 is due Carry out maintenance 2 (inspect vessel internally, every 5 years)

48

Maintenance 3 is due Carry out maintenance 3 (strength inspection to vessel, every 10 years)

49

Maintenance 4 is due Carry out maintenance 4 (inspect electrical equipment, every 1,5 years)

64

Low pressure alarm System pressure is lower than “Low Pressure Alarm”

65

Higher pressure exceeded System pressure is higher than “High Pressure Alarm”

66

Water Level below minimum value Water level in a vessel is lower than “Low level limit”

72

Temperature too high The temperature on the automat inlet is higher than 70°C. Please use an

intermediate vessel

73

Time between refill processes too short System requires to much refill. Potential leakage

74

Number of refills within certain time exceeded System requires to much refill. Potential leakage

7.6 Restarting

Aer long periods of downtime:

• If this downtime was planned or scheduled, turn OFF the control unit and close o the lockshield valves to the system and

the isolating valve to the top-up line. Aer that decompress and then drain the water area. We recommend you carry out

maintenance before restarting (see Maintenance section).

• Use the commissioning records for restarting and check especially for system changes that can lead to other operating

conditions of the expansion automat (e.g. system pressure).

If the power supply has failed:

• The target parameters and default settings for pressure, aeration and top-up will remain unchanged, meaning automatic

operation will resume automatically when power is restored (control unit ON). Extraordinary system operating conditions

(e.g. cooling to below the default setting) may fall outside the permitted settings of the expansion vessel.

Caution: please ensure that when the system cools down or warms up, the minimum or maximum system pressure

does not exceed or fall below the permitted operating pressure. Under- and over-pressure safety for operation of

heating or cooling systems are not within the standard scope of supply of the Flamcomat MK.

Check the automat’s operation once power supply has been restored and, if necessary, set the actual date and time values

(overview menu options).

Loading...

Loading...