FlashCut CNC Section 6 Drive Settings

L

oa

d

Inertia

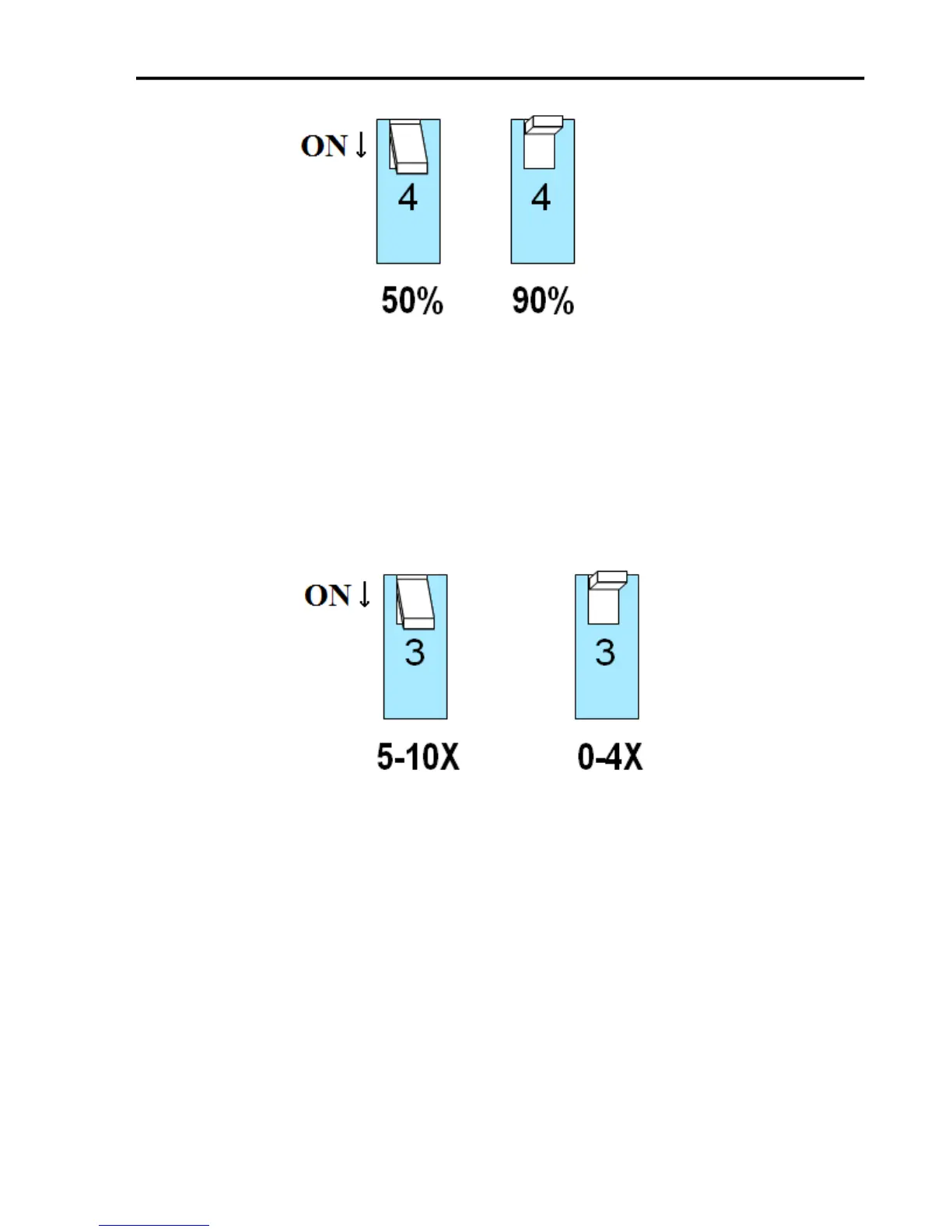

The drives include anti-resonance and electronic damping features which

greatly improve motor performance. To perform optimally, the drive must

understand the electromechanical characteristics of the motor and load. Most

of this is done automatically when you select the motor by setting the rotary

switch. To further enhance performance you must set a switch to indicate the

appropriate inertia ratio of the load and motor. The ranges are 0 to 4X and 5

to 10X. Simply divide the load inertia by the rotor inertia to determine the

ratio, then set switch 3 accordingly, as shown.

Step Size

The drive module requires a source of step pulses to command motion. This

may be a PLC, an indexer, a motion controller or another type of device. The

only requirement is that the device be able to produce step pulses whose

frequency is in proportion to the desired motor speed, and be able to

smoothly ramp the step speed up and down to produce smooth motor

acceleration and deceleration.

Smaller step sizes result in smoother motion and more precise speed, but also

require a higher step pulse frequency to achieve maximum speed. The

smallest step size of the drives is 1/20,000

th

of a motor turn while the

maximum step rate of the signal generator is typically between 50,000 and

Loading...

Loading...