Maintenance of the Machine

74

04/03/2020 218333

Only for SB/TB/TBZ 23/25 Plus types

In these machine types, 2 ribbed V-belts are installed on 3 axles so that 2

ribbed V-belts must be tensioned if necessary. If the front ribbed V-belt is ten-

sioned, the rear ribbed V-belt must also be tightened.

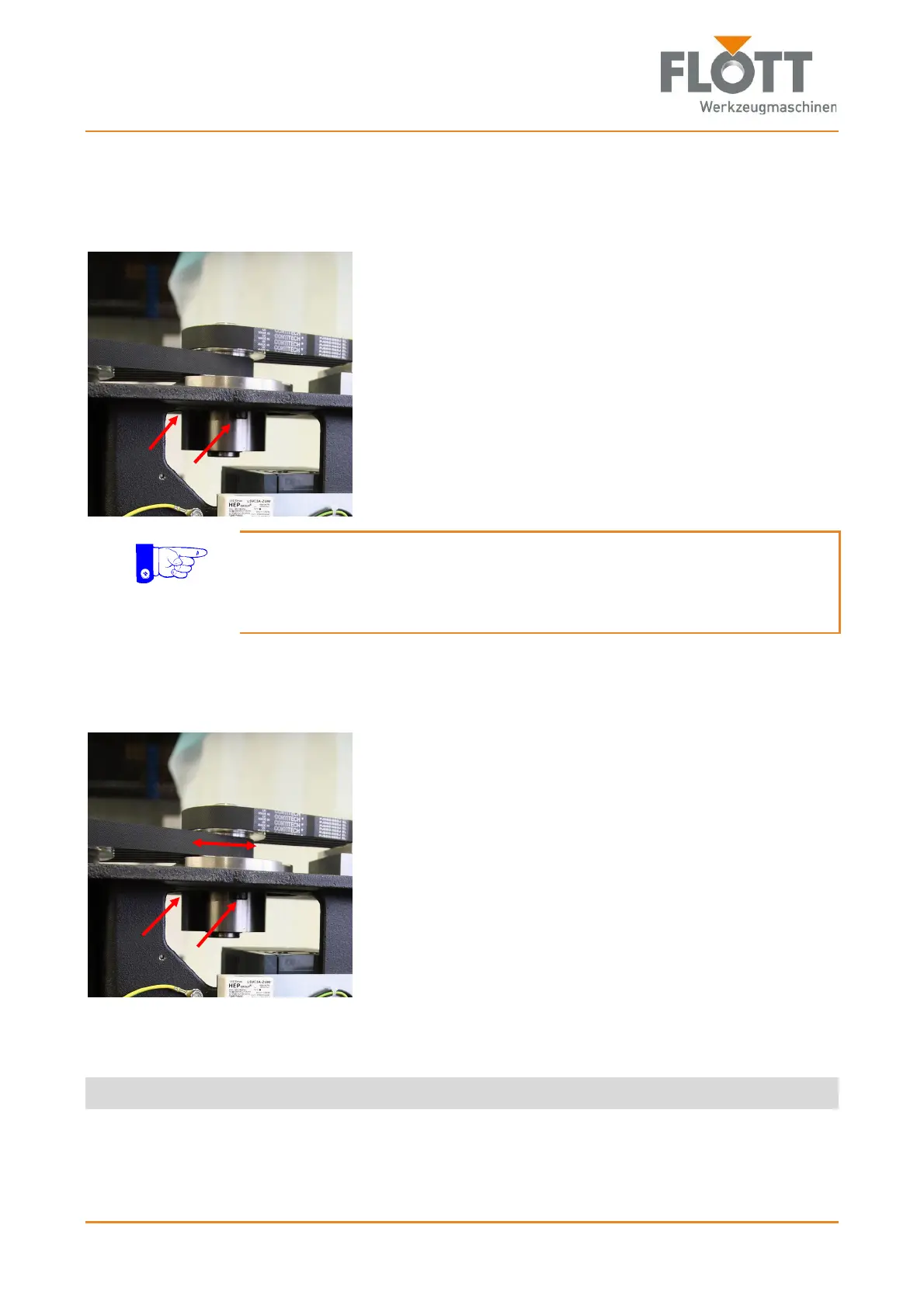

4. On the underside of the central axle bearing, loosen the

two size 6 hexagon socket screws to remove the axle to-

gether with the transmission belt pulley.

This will relieve the tension of the ribbed V-belts.

Note

Please note that only original spare parts from the manufacturer May be used.

If you use other spare parts, the manufacturer gives no warranty and is not li-

able for functionality and safety of the machine.

5. If necessary:

Remove the damaged ribbed V-belt and replace it by a new one.

When installing the new ribbed V-belt, make sure it is seated correctly and

in alignment on both pulleys.

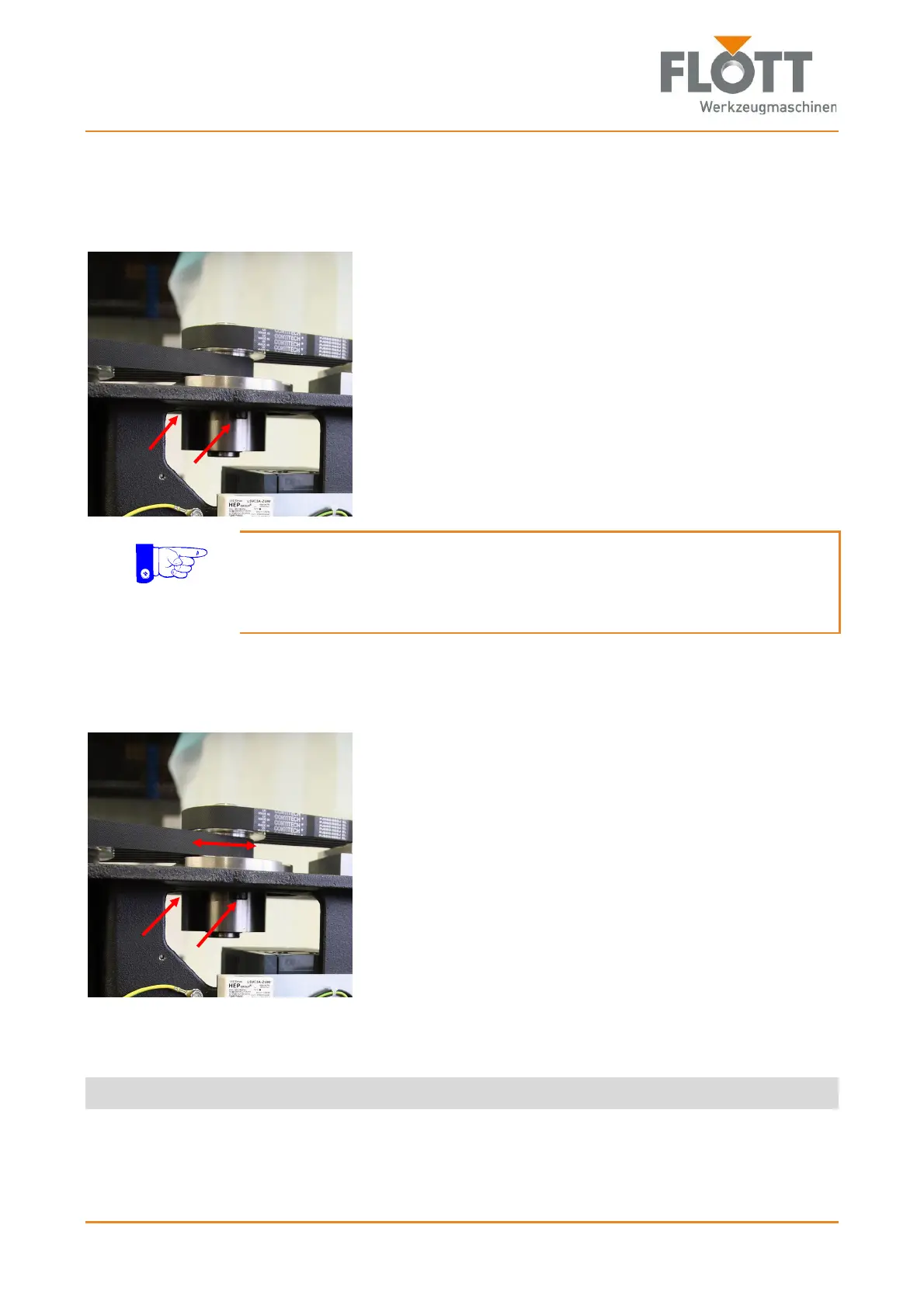

6. Clamp the ribbed V-belt in by

slightly pushing the middle axle bearing backwards

with one hand,

checking the tension of the ribbed V-belt with the other

hand.

The tension is correct if the ribbed V-belt between the

pulleys can be pressed in 3-5 mm.

7. Tighten the two hexagon socket screws on the underside

of the middle axle bearing.

8. Then check that the ribbed V-belt is seated correctly and

runs smoothly when turning the front pulley by hand.

9. Then also clamp the rear ribbed V-belt (see section 9.4

For all SB/TB/TBZ 23 Plus types, page 72).

The ribbed V-belts are now replaced (if necessary) and correctly tensioned.

Loading...

Loading...