Before Using the Machine

36

04/03/2020 218333

5.3 Connecting the Machine Electrically

Warning

Danger due to faulty electrical connection.

Observe the electrical connection values in the operating manual and the rat-

ing plate when connecting the machine.

Excessive connection voltage may cause operator injury and damage to

the machine.

If the connection voltage is too low, the machine motor may be damaged.

The earthing contact plug has an earthing conductor and may only be re-

placed with an original component.

If local and national regulations prescribe upstream protection by a residual-

current protective device (RCD), you must use a type A device for single-

phase converters and a type B device for three-phase converters according

to IEC 60755. This device must have the following characteristics:

Filtering high-frequency currents,

A time delay which prevents tripping caused by loading capacitance and

stray capacitance on power-up. This delay is not possible with 30 mA de-

vices. In this case, select devices that are insensitive to unintentional trip-

ping.

1. Make sure, that

A protective conductor terminal is present

There is a mains fuse of 16 A

The differential current (leakage current) is <7.5 mA.

Note: Due to the construction the leakage current is > 3.5 mA, caused by

an EMC filter. See also the following points from DIN VDE 0701-0702:

5.5 Measurement of the protective conductor current and Annex D:

Of 5.5 Measurement of the protective conductor current.

2. Only for SB/TB/TBZ 18 Plus Before connecting the machine to the power

supply, as a precaution press the emergency stop button to prevent unde-

sired start-up of the machine.

3. Insert the earthing contact plug into a suitable socket of the mains supply.

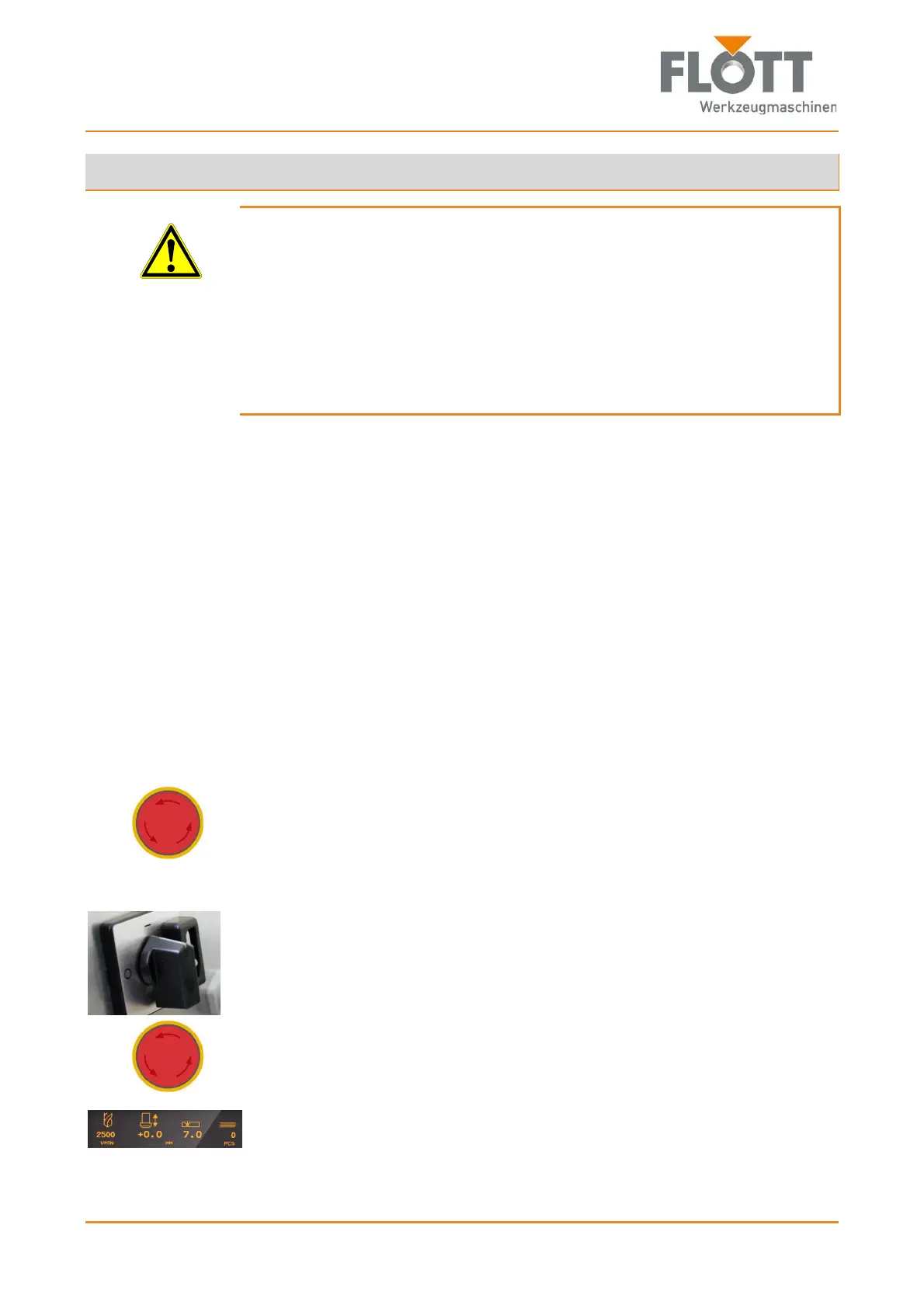

4. Only for SB/TB/TBZ 20 Plus, 23 Plus and 25 Plus:

Turn the main switch below the protective hood towards I to switch on the

power supply of the machine.

5. Unlock the emergency stop button by turning it counter clockwise. As soon

as the emergency stop button is unlocked

The machine control system reboots

The display and the drill light are switched on and

The control system is started. There is no rotational movement and the

display is turned on.

Loading...

Loading...