Maintenance of the Machine

70

04/03/2020 218333

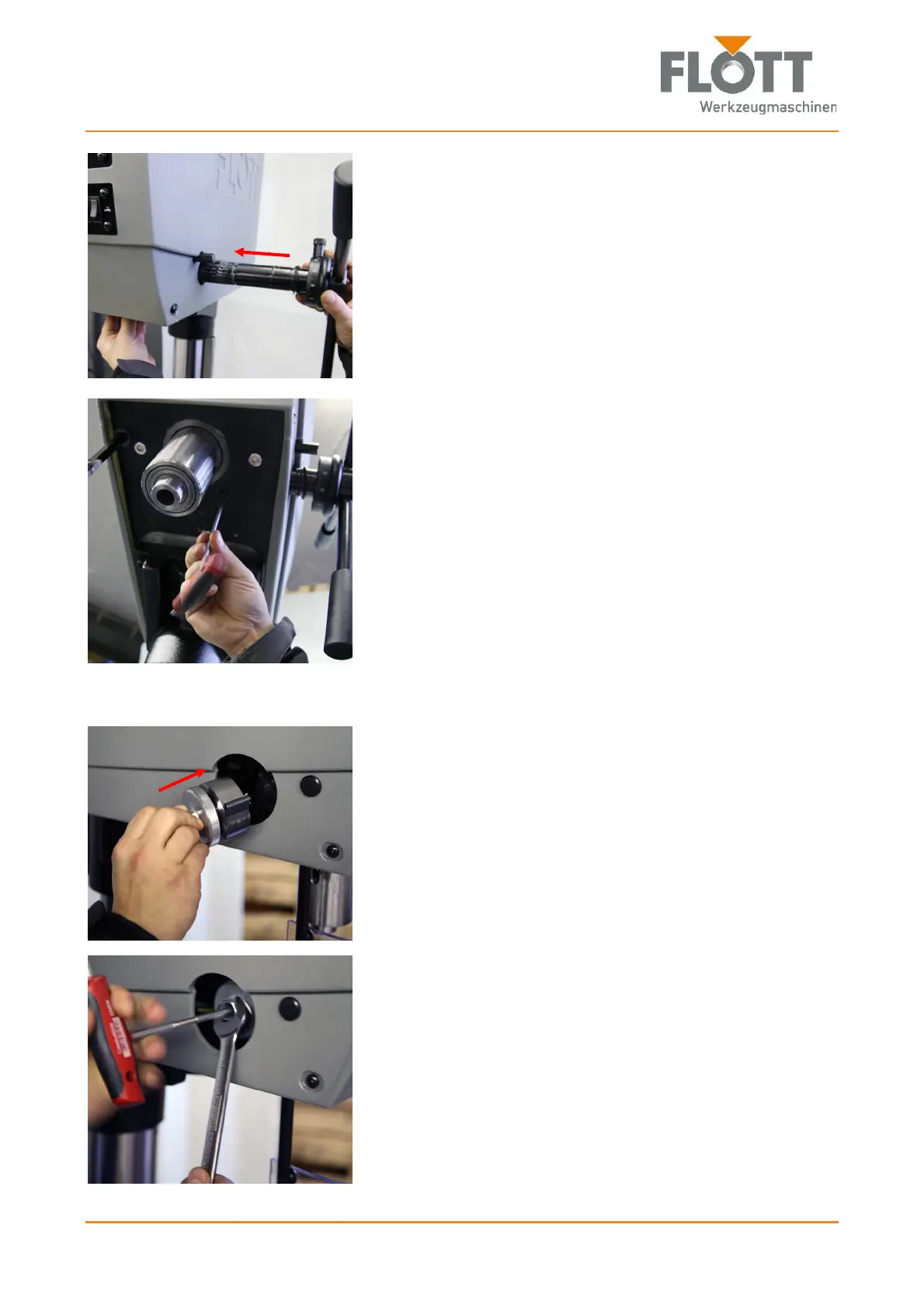

12. Push the complete three-arm-lever with pinion shaft

slowly into the guide of the quill as far as it will go.

You have to

Make sure not to force the pinion shaft into the guide

as this can damage the very accurately machined quill

surface

If necessary, turn the pinion shaft slightly during inser-

tion so that it slides into the teeth.

13. In the area of the spindle, screw in the size 4 hexagon

socket screw to fix the pinion shaft in position.

14. Turn the quill with the three-arm-lever upwards and fix it

with the drilling depth limiter.

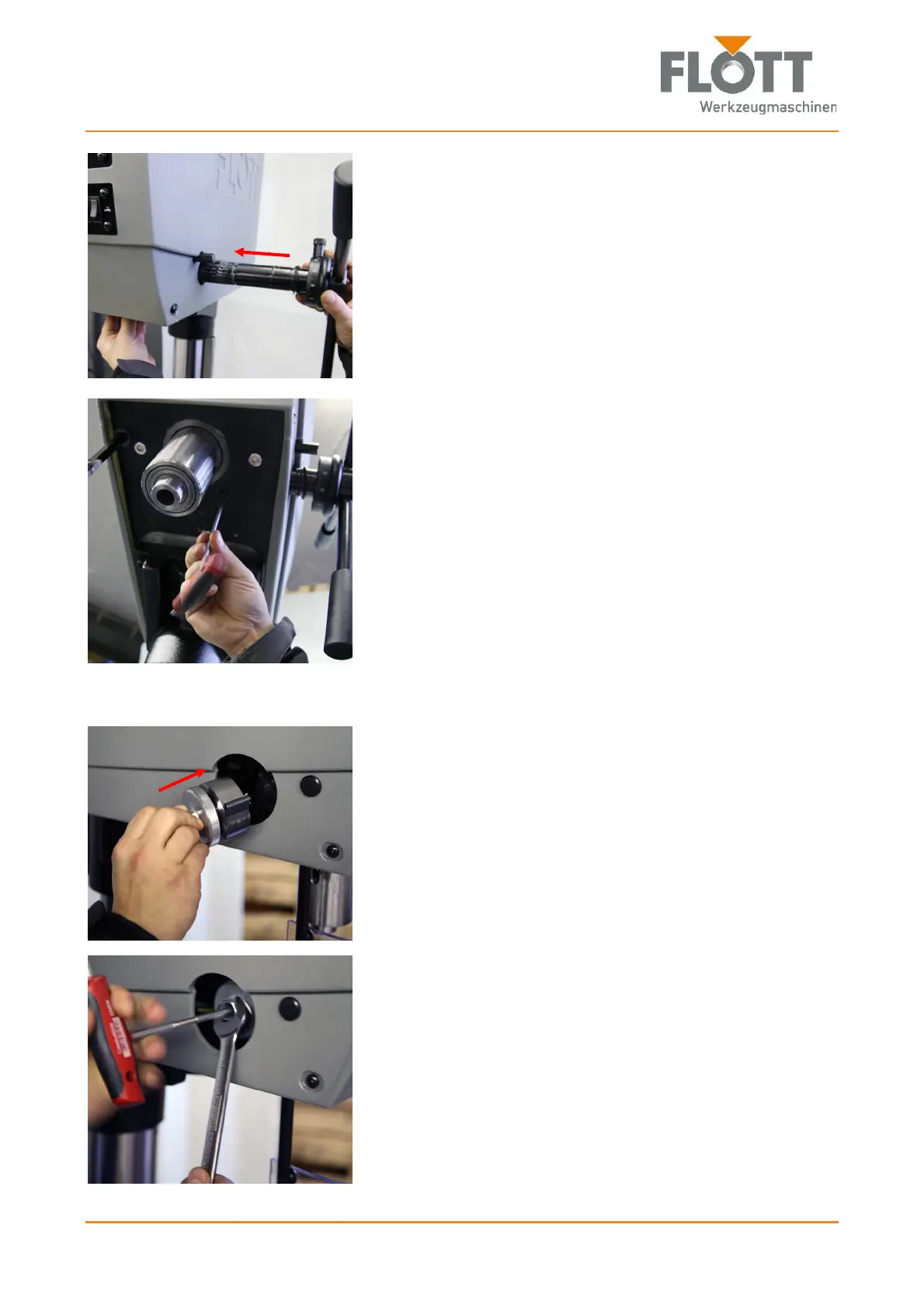

15. Insert the spiral spring with the clamping flange into the

opening on the left side of the protective hood.

16. Slightly tighten the hexagon socket screw of the assem-

bly by hand.

17. Clamp the spiral spring approx. ½ turn clockwise with the

WAF19 hexagon wrench.

18. Attach the spiral spring with the clamping flange of the

three-arm-lever using the size 6 hexagon wrench to

tighten the spiral spring.

Loading...

Loading...