28 | M-416 ©FlowInternationalCorporation

HYPLEX PRIME PUMP

Maintenance & Service Manual

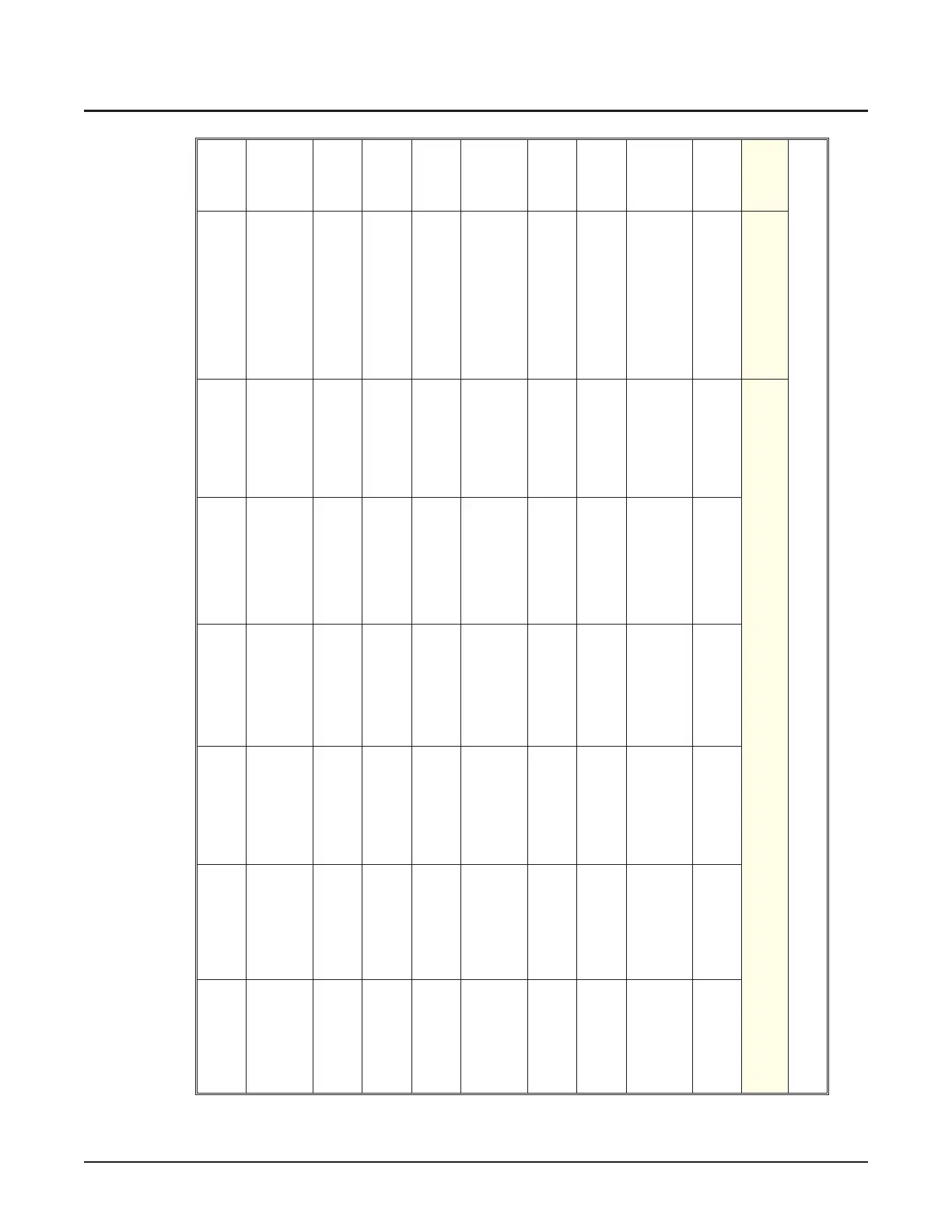

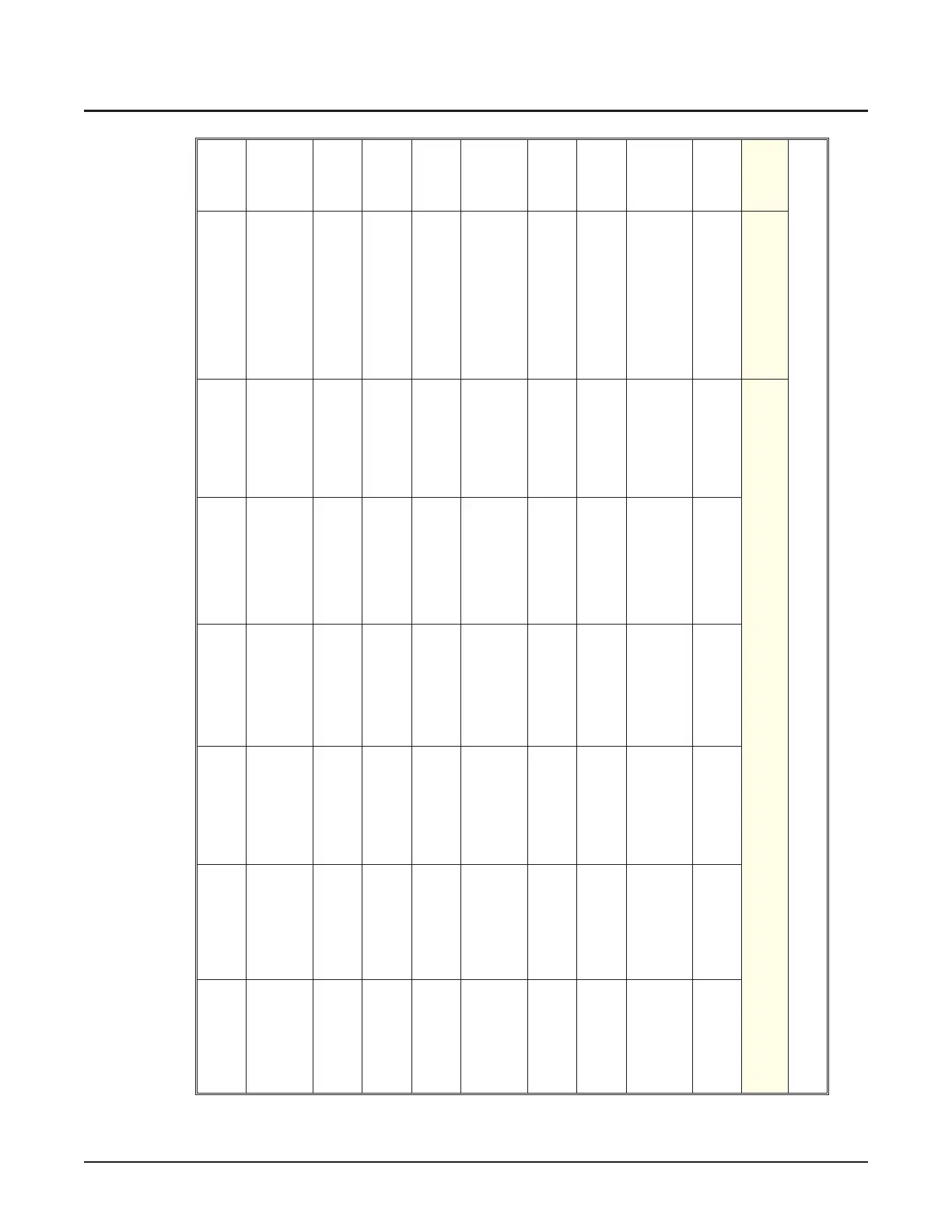

50 hp HyPlex Prime maintenance schedule

Hourly

Interval

Kit Service procedures

300

Dynamic Seal Replace UHP

seal & rod seal

Lap inlet check

valve components

600

Minor Maintenance Replace UHP

seal & rod seal

Lap inlet check

valve components

Replace outlet

check valve

components

Replace filler

tube sleeve

Service subplate

adapter

Change PCV

poppet & seat

900

Major Maintenance Replace UHP

seal & rod seal

Replace all check

valve components

Replace UHP

cylinder

Replace UHP

seal carrier

Service subplate

adapter

Change PCV

poppet & seat

1200

Dynamic Seal Replace UHP

seal & rod seal

Lap inlet check

valve components

1500

Minor Maintenance Replace UHP

seal & rod seal

Lap inlet check

valve components

Replace outlet

check valve

components

Replace filler

tube sleeve

Service subplate

adapter

Change PCV

poppet & seat

1800

Major Maintenance Replace UHP

seal & rod seal

Replace all check

valve components

Replace UHP

cylinder

Replace UHP

seal carrier

Service subplate

adapter

Change PCV

poppet & seat

PCV Replace PCV

plunger

Replace bearing

assembly & seals

2100

Dynamic Seal Replace UHP

seal & rod seal

Lap inlet check

valve components

2400

Minor Maintenance Replace UHP

seal & rod seal

Lap inlet check

valve components

Replace outlet

check valve

components

Replace filler

tube sleeve

Service subplate

adapter

Change PCV

poppet & seat

2700

Major Maintenance Replace UHP

seal & rod seal

Replace all check

valve components

Replace UHP

cylinder

Replace UHP

seal carrier

Service subplate

adapter

Change PCV

poppet & seat

At fixed intervals for the life of the pump, you must perform a mandatory maintenance kit installation.

For all HyPlex Prime pumps (except the standalone version), the Service information feature in FlowCUT is factory-set to remind the operator

10 hours before the next required maintenance hour mark.

Loading...

Loading...