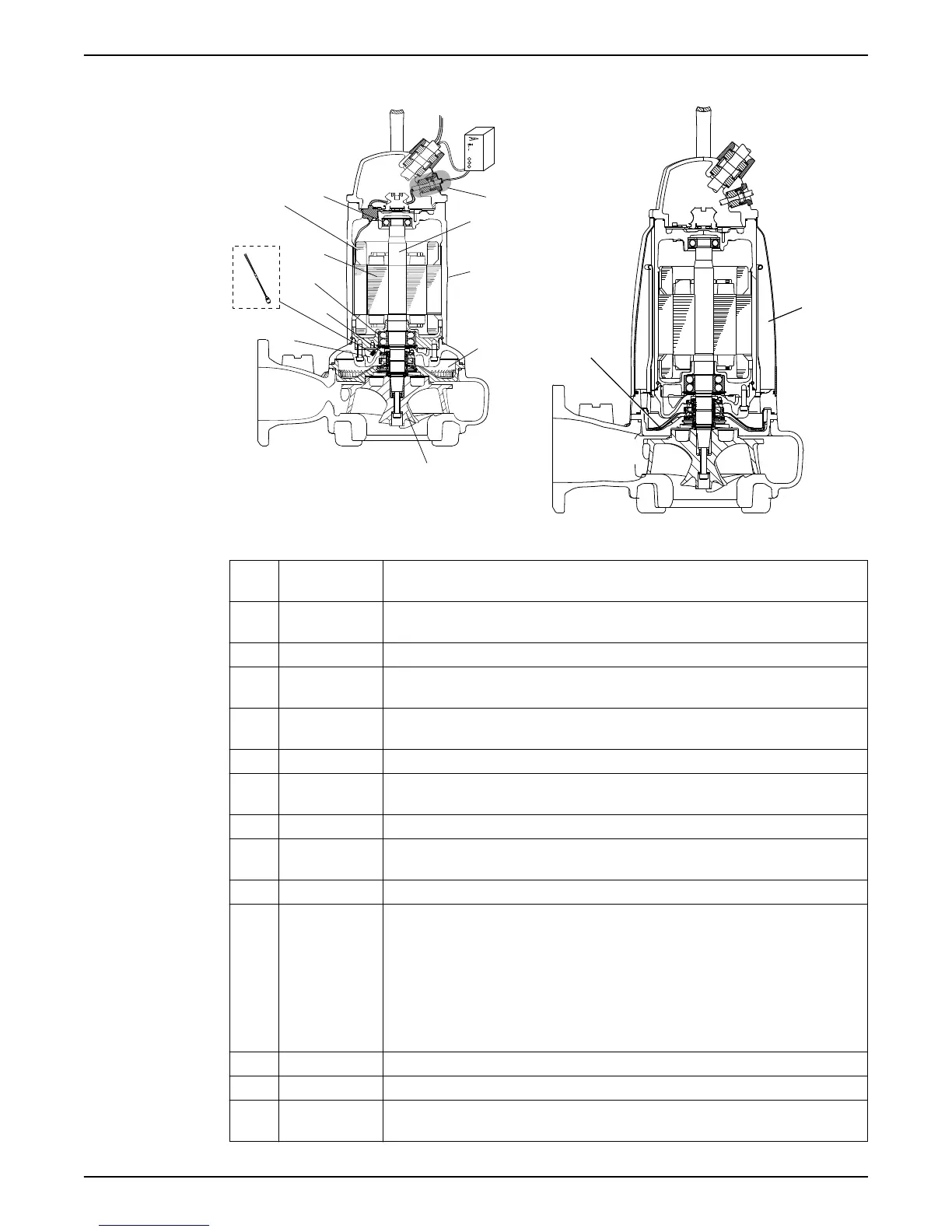

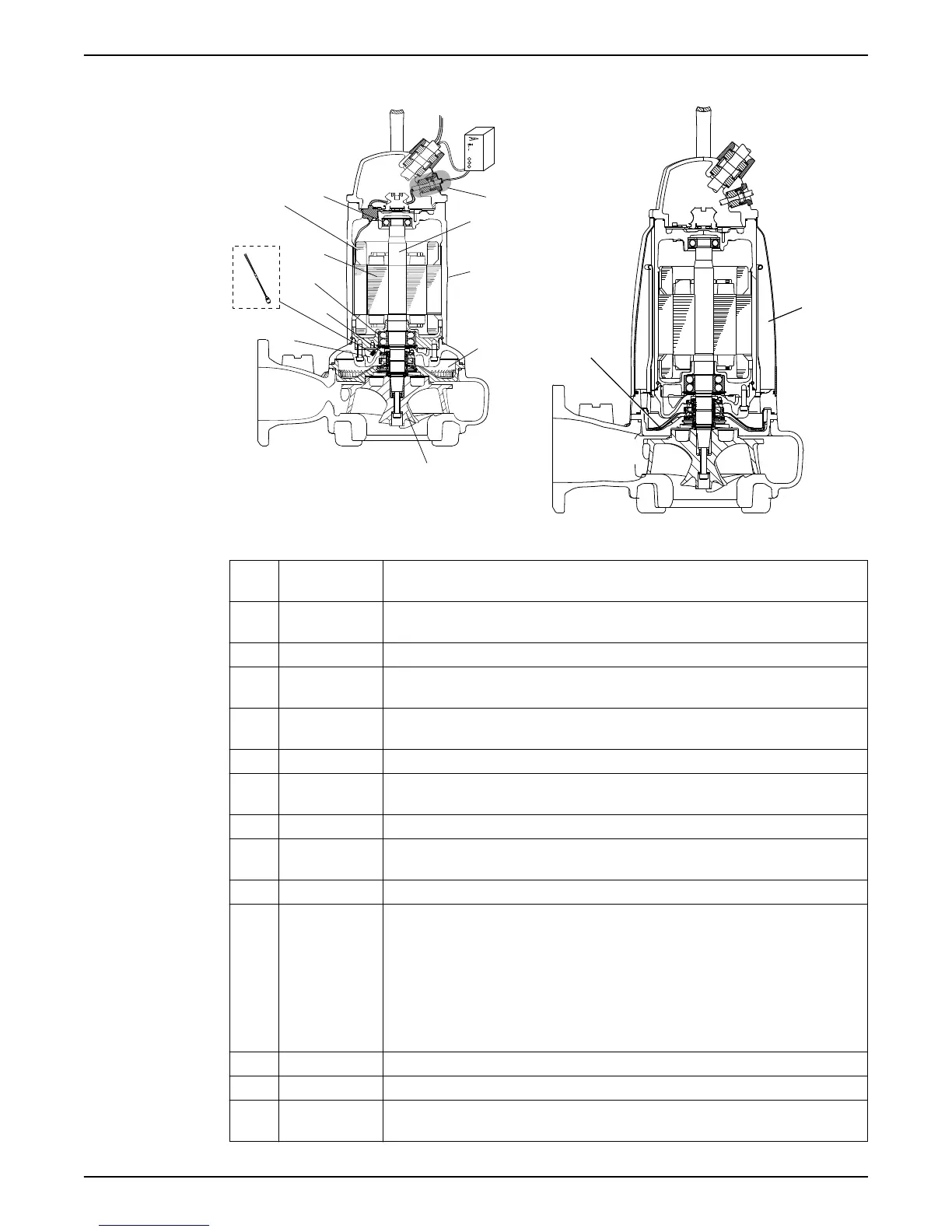

Parts

1

11

10

9

8

7

2

3

6

12

13

14

WS000850A

Figure 1: Without cooling jacket

Figure 2: With cooling jacket

Positio

n

Denomination Description

1 Monitoring

sensor

Optional sensor. For information about sensors, see Monitoring equipment (page

13).

2 Shaft Stainless steel, with an integrated rotor

3 Cooling without

jacket

The pump is cooled by the ambient liquid.

4 Cooling with

jacket

The motor is cooled by a closed loop system. An integrated coolant pump circulates the

coolant whenever the pump is operated.

5 Flow diffuser Provides heat transfer from the coolant to the pumped fluid.

6 Seal housing Includes a coolant that lubricates and cools the seals; the housing acts as a buffer

between the pumped fluid and the electric motor

7 Impeller N-impeller, a semi-open, two-vane impeller

8 Inspection

chamber

Equipped with an FLS10 leakage sensor to prevent damages to the motor

9 FLS10

For information about FLS10, see Monitoring equipment (page 13).

10 Mechanical seals Made of one of the following alternatives:

• Alternative 1

• Inner seal: corrosion-resistant cemented carbide WCCR/WCCR

• Outer seal: corrosion-resistant cemented carbide WCCR/WCCR

• Alternative 2

• Inner seal: corrosion-resistant cemented carbide WCCR/WCCR

• Outer seal: silicon carbide RSiC/RSiC

11 Main bearings Consisting of a two-row angular contact ball bearing

12 Motor

For information about the motor, see Motor data (page 67).

13 Thermal contact/

Thermistors

For information about the thermal contact and thermistors, see Monitoring

equipment (page 13).

Product Description

12 Flygt 3202 Installation, Operation, and Maintenance Manual

Loading...

Loading...