8. Lower the pump along the guide bars.

9. Secure the motor cable:

a) Fasten the permanent lifting device to the pump and to the access frame. For

example, you can use a stainless-steel lifting chain with shackles.

b) Fasten the cable to the cable holder.

Make sure that the cable cannot be sucked into the pump inlet or that it is neither

sharply bent, or pinched. Support straps are required for deep installations.

c) Connect the motor cable and the starter and monitoring equipment according to

the separate instructions.

Make sure that the impeller rotation is correct. For more information, see Check

the impeller rotation (page 37).

Clean all debris from the sump before starting the pump.

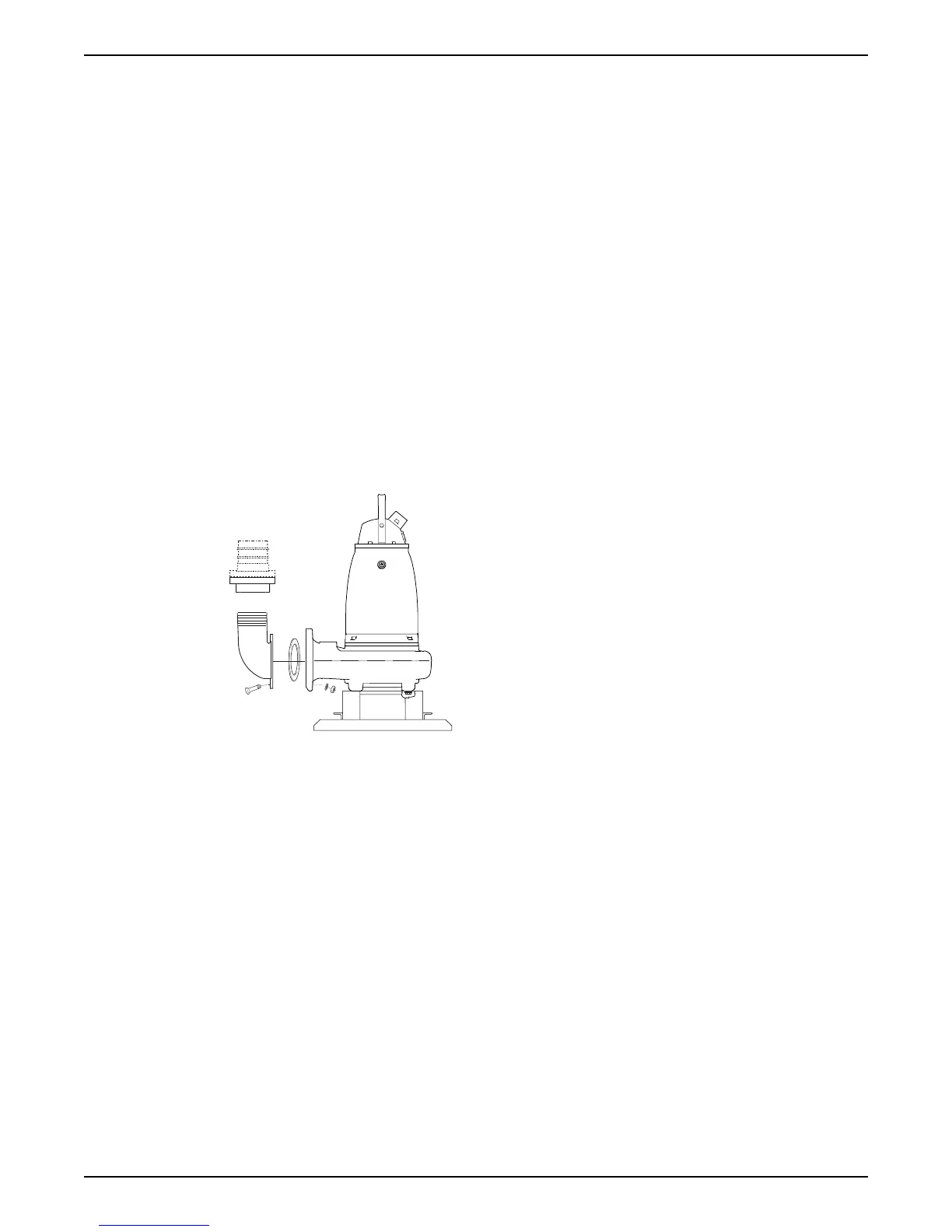

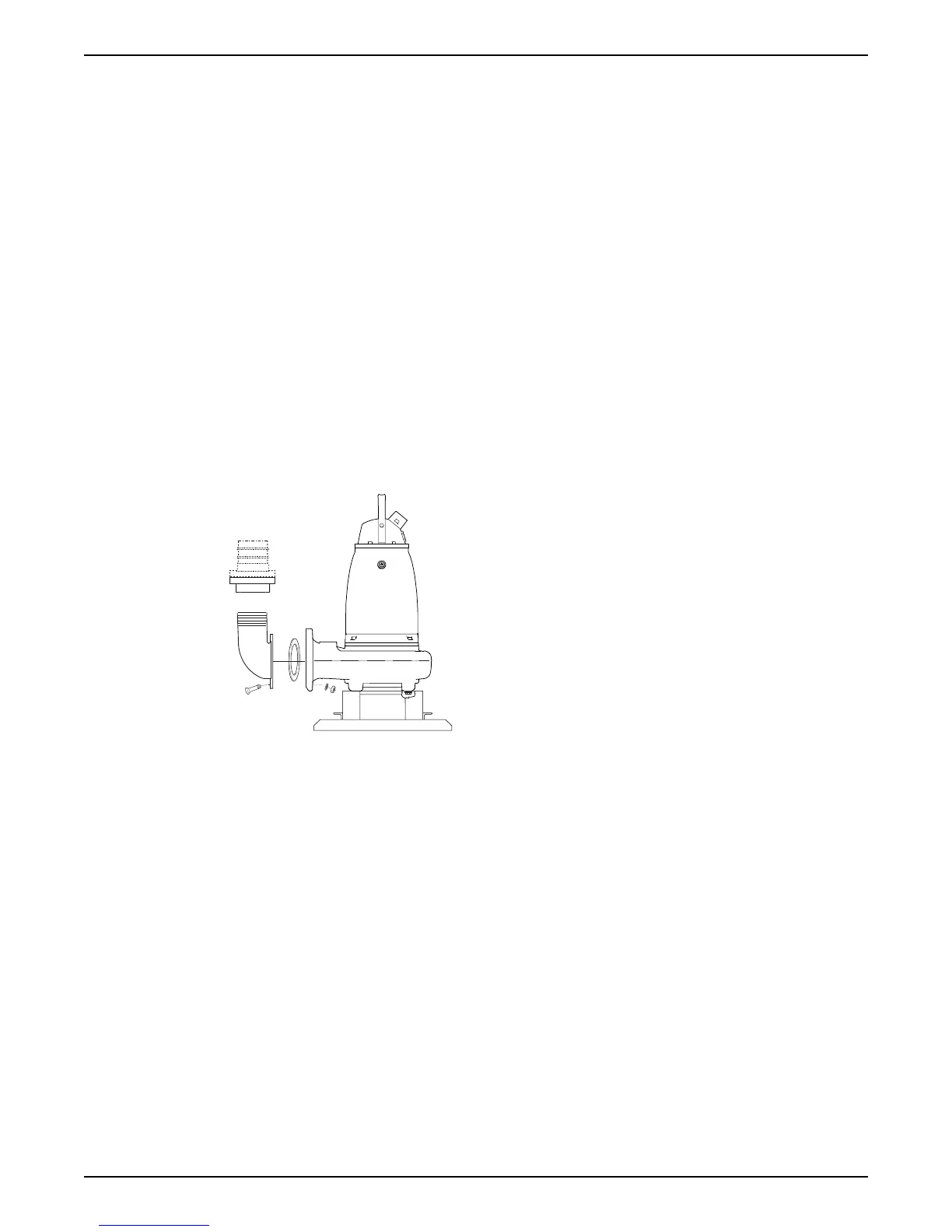

Install with S-installation

In the S-installation, the pump is transportable and intended to operate either completely

or partially submerged in the pumped liquid. The pump is equipped with a connection for

hose or pipe and stands on a base stand.

These requirements and instructions only apply when the installation is made according

to the dimensional drawing. For information about the different installation types, see

Parts List.

Figure 5: S-installation

1. Run the cable so that it has no sharp bends. Make sure that it is not pinched, and

cannot be sucked into the pump inlet.

2. Connect the discharge line.

3. Lower the pump into the sump.

4. Place the pump on the base and make sure it cannot fall over or sink.

Alternatively, the pump can be suspended with a lifting chain just above the sump

bottom. Make sure that the pump cannot rotate at startup or during operation.

5. Connect the motor cable and the starter and monitoring equipment according to the

separate instructions.

Make sure that the impeller rotation is correct. For more information, see Check the

impeller rotation (page 37).

Install with T/Z-installation

This installation is not applicable for these versions:

• .660

• .670

• .860

• .870

Installation

20 Flygt 3202 Installation, Operation, and Maintenance Manual

Loading...

Loading...