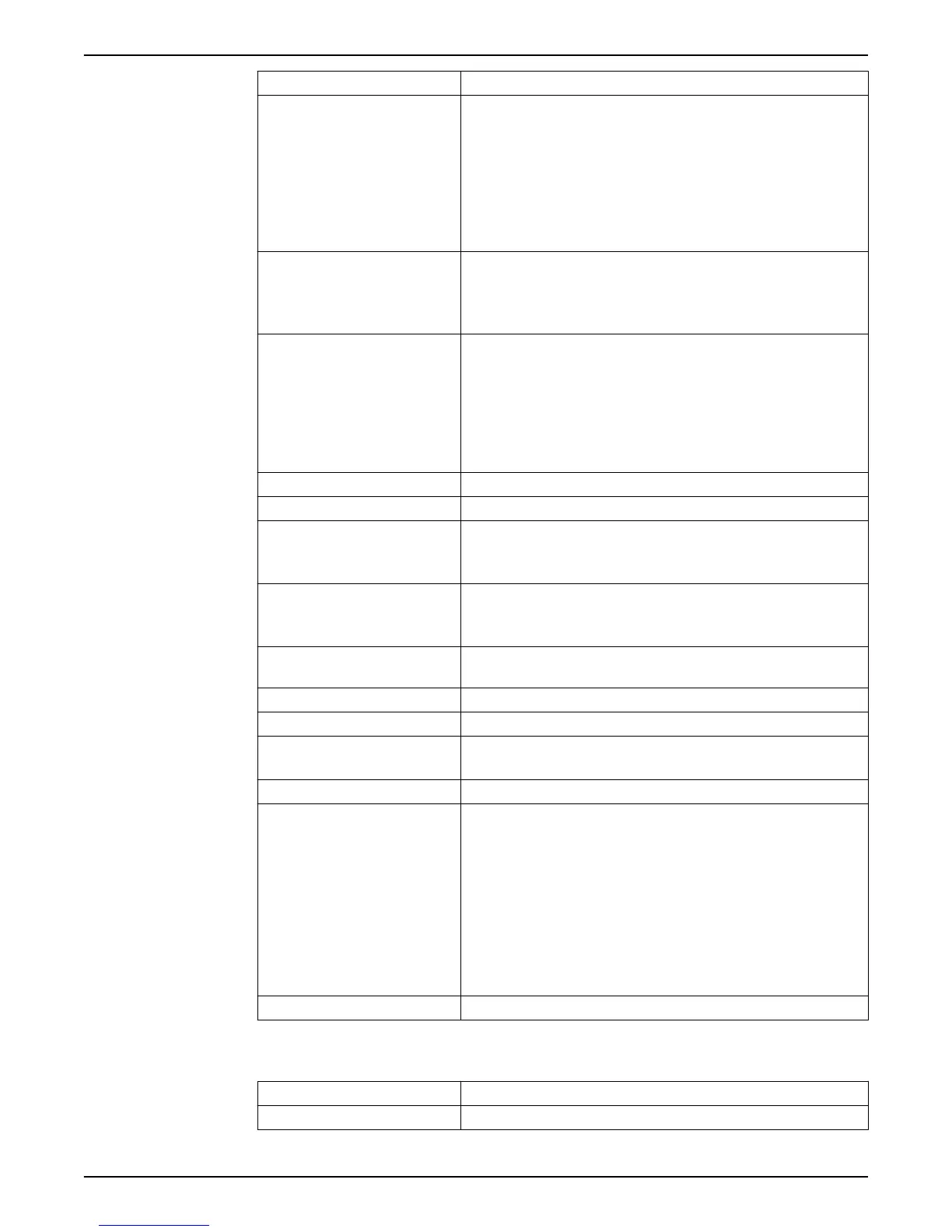

Service item Action

Inspection chamber 1. Drain all liquid, if any.

2. Check the resistance of the leakage sensor.

If the pump is connected to the MAS 711 then it is recommended

that the sensors be checked in the MAS 711 unit. Otherwise, use a

multimeter.

For values, see Sensor-connection (page 32). Make sure to

select values for the appropriate monitoring equipment and sensor

combination.

Insulation Use a megger maximum 1000 V.

1. Check that the resistance between the earth (ground) and phase

lead is more than 5 megohms.

2. Conduct a phase-to-phase resistance check.

Junction box 1. Check that it is clean and dry.

2. Check the resistance of the leakage sensor.

If the pump is connected to the MAS 711 then it is recommended

that the sensors be checked in the MAS 711 unit. Otherwise, use a

multimeter.

Normal value approximately 1530 ohms, alarm approximately

330 ohms.

Level regulators Check the condition and functionality.

Lifting device Check that local safety regulations are followed.

Lifting handle 1. Check the screws.

2. Check the condition of the lifting handle.

3. Replace if necessary.

O-rings 1. Replace the oil plug O-rings.

2. Replace the O-rings at the entrance or junction cover.

3. Grease the new O-rings.

Overload protection and other

protections

Check the correct settings.

Personnel safety devices Check the guard rails, covers, and other protections.

Rotation direction Check the impeller rotation.

Seal housing 1. Fill with new coolant, if necessary.

2. Check that the freezing point is lower than -13°C (9°F).

Terminal board Check that the connections are properly tightened.

Temperature sensors:

• Thermal contact

• Thermistor

• Pt 100

If the pump is connected to the MAS 711 then it is recommended that the

sensors be checked in the MAS 711 unit. Otherwise, use a multimeter.

Do not use a device applying a higher voltage than 2.5 V.

1. Disconnect the sensor leads.

2. Measure the resistance to check the status of the sensor and leads

according to values in Sensor-connection (page 32). Make sure

to select values for the appropriate sensor, monitoring equipment

and sensor combination.

3. Measure between each sensor lead to earth (ground) to establish

that the resistance is infinite (or at least several Megaohm).

Voltage and amperage Check the running values.

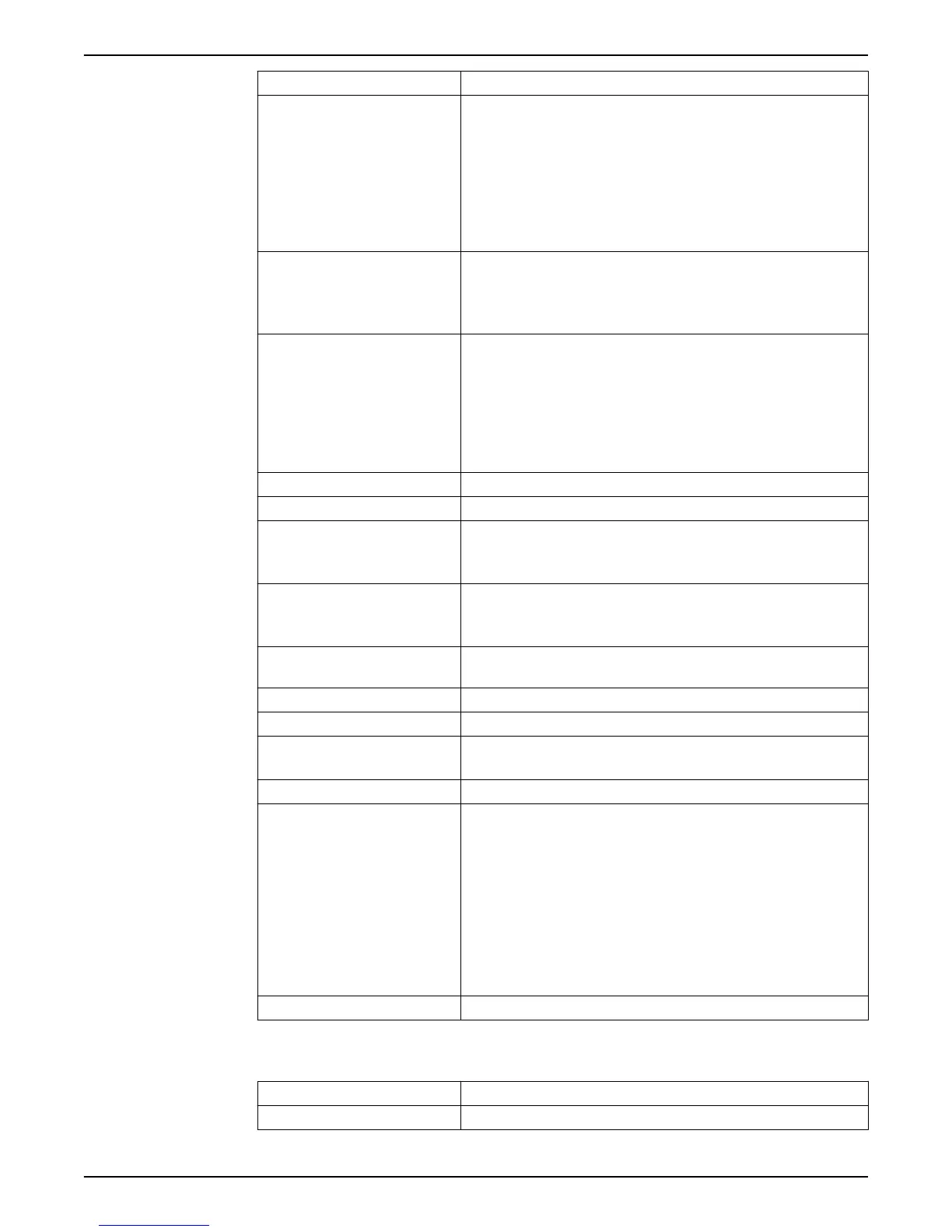

Major overhaul

For a major overhaul, take this action in addition to the tasks listed under Inspection.

Service item Action

Support and main bearing Replace the bearings with new bearings.

Maintenance

46 Flygt 3202 Installation, Operation, and Maintenance Manual

Loading...

Loading...