10

Installation and Operation Manual

SystemsSystems

2001 and 2002

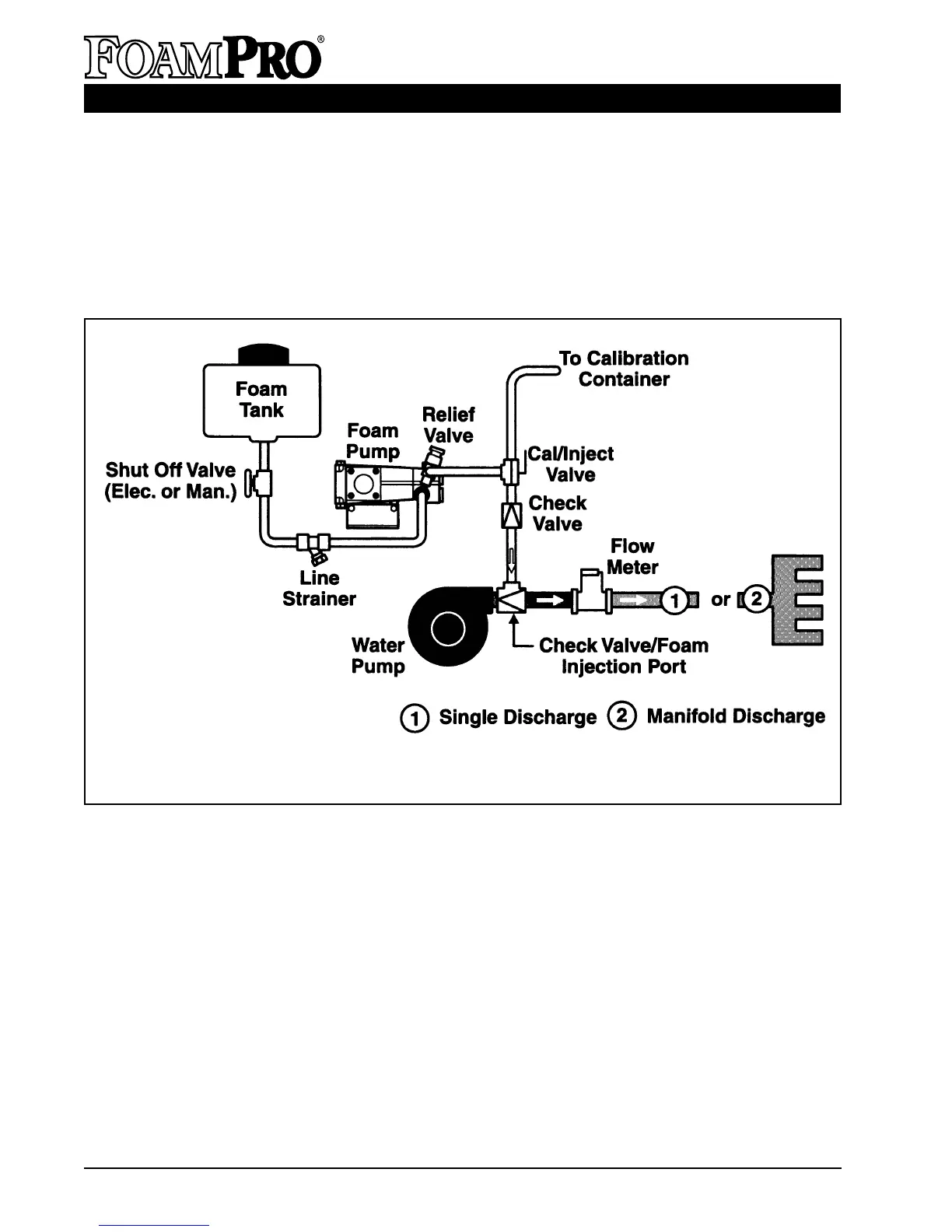

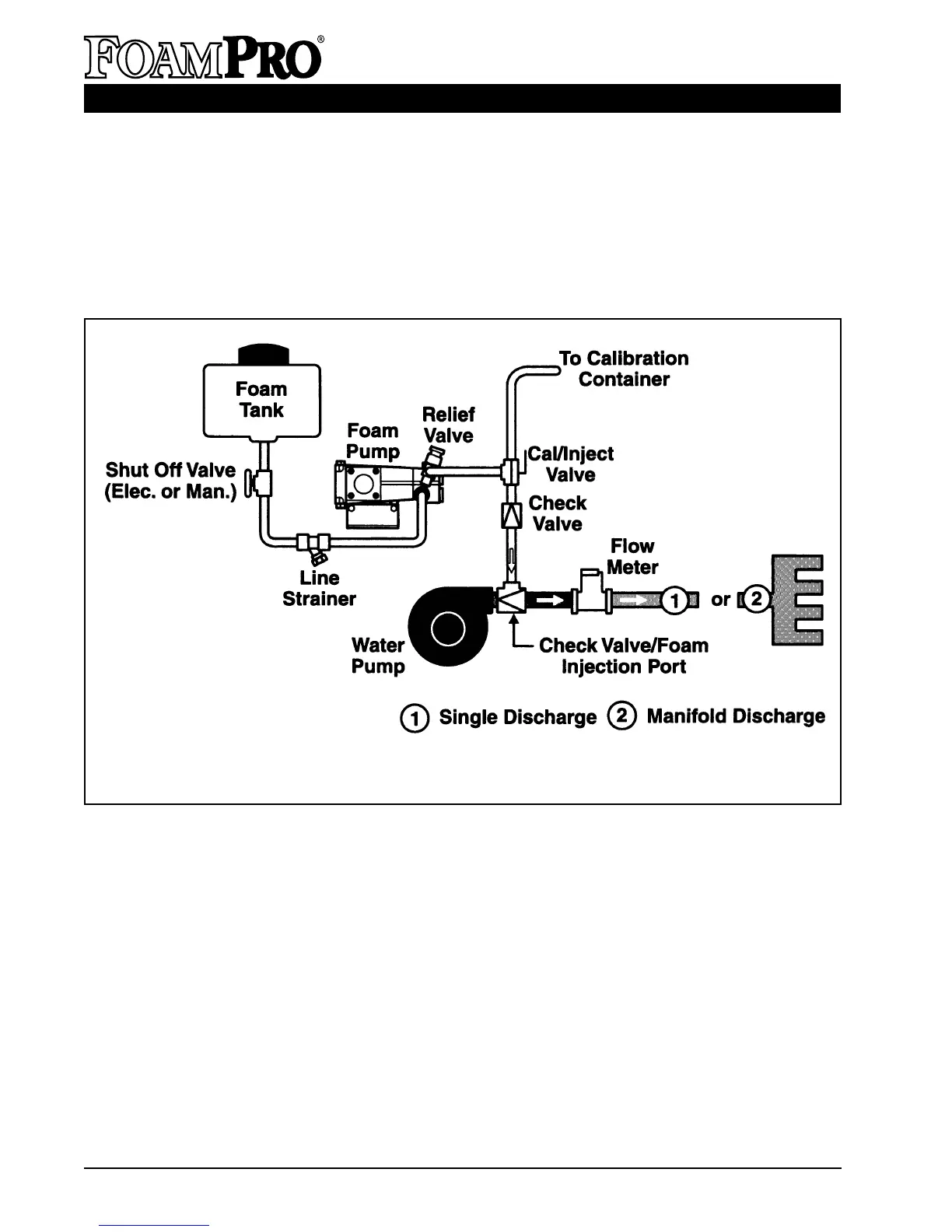

PLUMBING COMPONENT INSTALLATION

The following diagram (Figure 3) provides recommended guidelines for the location of the system

components that handle water, foam concentrate and foam solution. Note that additional options

such as dual tank systems, multiple flowmeters, etc., are covered by individual manuals included

with those systems; consider potential interferences.

Figure 3. FoamPro 2001/2002 System Piping

A. FOAM PUMP/MOTOR BASE ASSEMBLY

The foam pump/motor base assembly must be

mounted in a horizontal position (See Figure 5).

The base of the foam pump must be anchored

to a surface or structure that is rigid and of

adequate strength to withstand the vibration and

stresses of apparatus operation. Figure 4

provides the mounting dimensions for the

FoamPro 2001 and 2002 foam pump/motor

base assembly. It is required to use flexible

hose when making the hose connections to the

FoamPro 2001 and 2002. DO NOT hard pipe

the system.

Position the foam pump so the circuit breaker/

on-off switch is easily accessible. Also,

consider access requirements for checking and

changing the oil in the crankcase of the foam

pump. Be sure the foam concentrate hoses can

be properly routed to the inlets and outlets on

the foam pump. Foam concentrate should

gravity feed to the foam pump inlet from the

foam tank(s). The foam pump/motor base

assembly must be mounted in an area to avoid

excessive exhaust system heat buildup.

Protect the hoses and wiring from chafing and

abrasion during operation of the foam system.

Protect the foam pump base unit from excessive

road spray and debris. Although the system is

sealed and designed to be resistant to the harsh

environment of fire fighting apparatus, a

6

Loading...

Loading...