4

Installation and Operation Manual

SystemsSystems

2001 and 2002

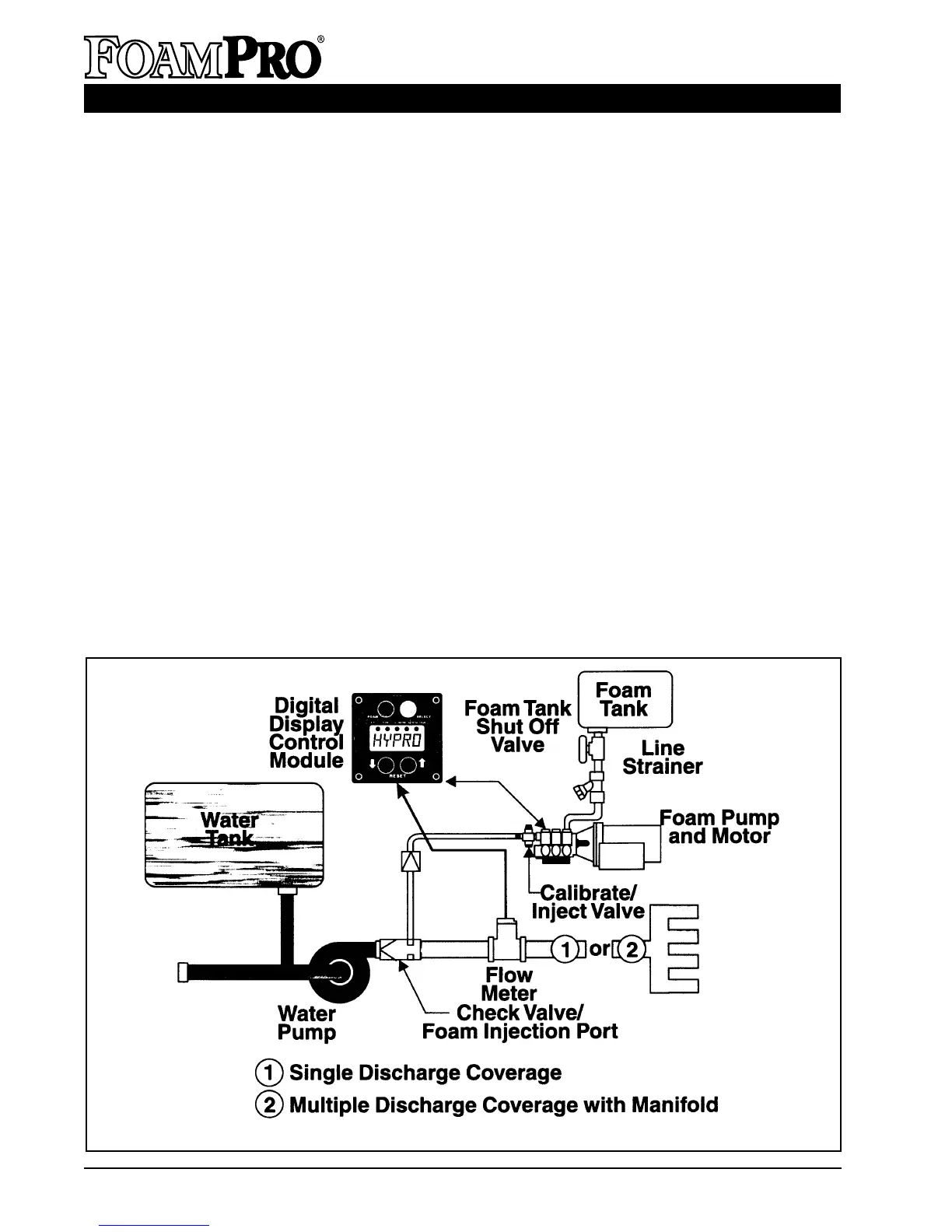

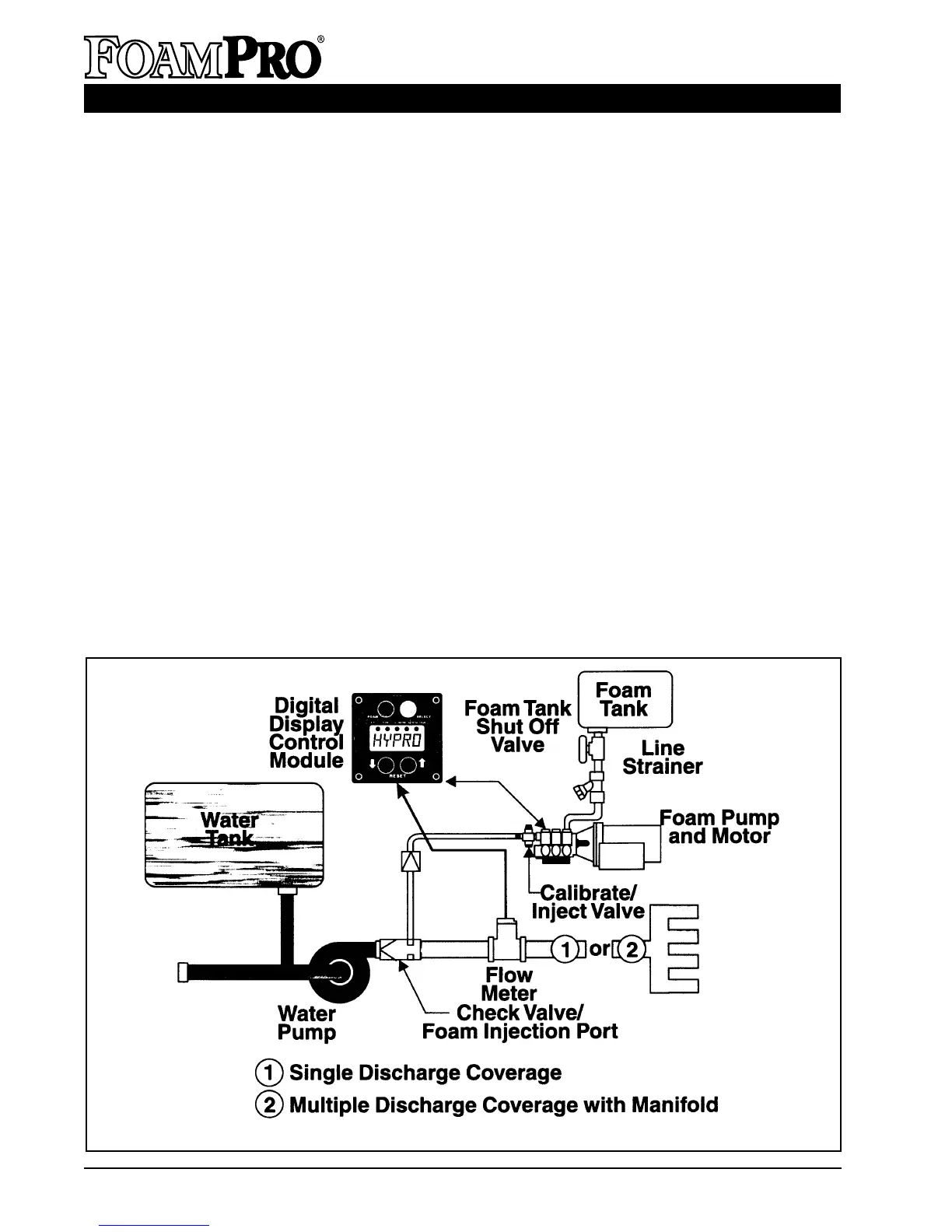

A QUICK LOOK AT HOW THE SYSTEM WORKS

The FoamPro 2001 and 2002 systems are

electric motor-driven, flow-based proportioning

systems that measure water flow and then inject

the proportional amount of foam concentrate to

maintain the preset percentage. The basic

FoamPro 2001 and 2002 systems are shown in

Figure 1. The systems will accurately deliver

from 0.1% to 3.0% foam concentrate to the

foam injector fitting. The flowmeter measures

the water flow and sends a signal to the Digital

Display Control Module. Another sensing

device monitors the foam pump output.

Constant comparison of these two information

signals by the computer ensures maintenance

of the desired proportion of foam concentrate at

all times based on the water flow rate,

independent of any variations in fire pump

intake or discharge pressures. As water flow

Figure 1. FoamPro System Layout

increases or decreases, the foam concentrate

rate of injection is increased or decreased

automatically to correspond to the water flow.

Foam concentrate is injected directly into the

water stream on the discharge side of the water

pump. It is then fed as foam solution by the

main fire pump into a standard fog nozzle, an

air aspirated nozzle, or CAFS equipment.

Since foam is injected on the discharge side of

the fire pump and check valves are to be used

at installation, contamination of the booster

tank, fire pump and relief valve with foam

concentrate is eliminated.

Order optional system components listed in

Section 3 to accommodate system design and

requirements.

2

Loading...

Loading...