33

Installation and Operation Manual

SystemsSystems

2001 and 2002

PRIMING THE FOAM PUMP WHEN FOAM

TANK HAS RUN DRY

In some instances, the foam tank may run dry

while operating the FoamPro system. The foam

pump is designed to pump liquid. When the fire

pump is running, the foam pump cannot pump

air efficiently against 100 to 150 psi back

pressure. To re-establish foam concentrate flow

quickly, the following procedure can be used.

MAINTENANCE

1. Monthly: Inspect wiring, hoses, flow meters,

and connections for tightness, corrosion,

leaks and/or damage.

2. Monthly: Remove and clean the foam

strainer screen(s). Flush as required.

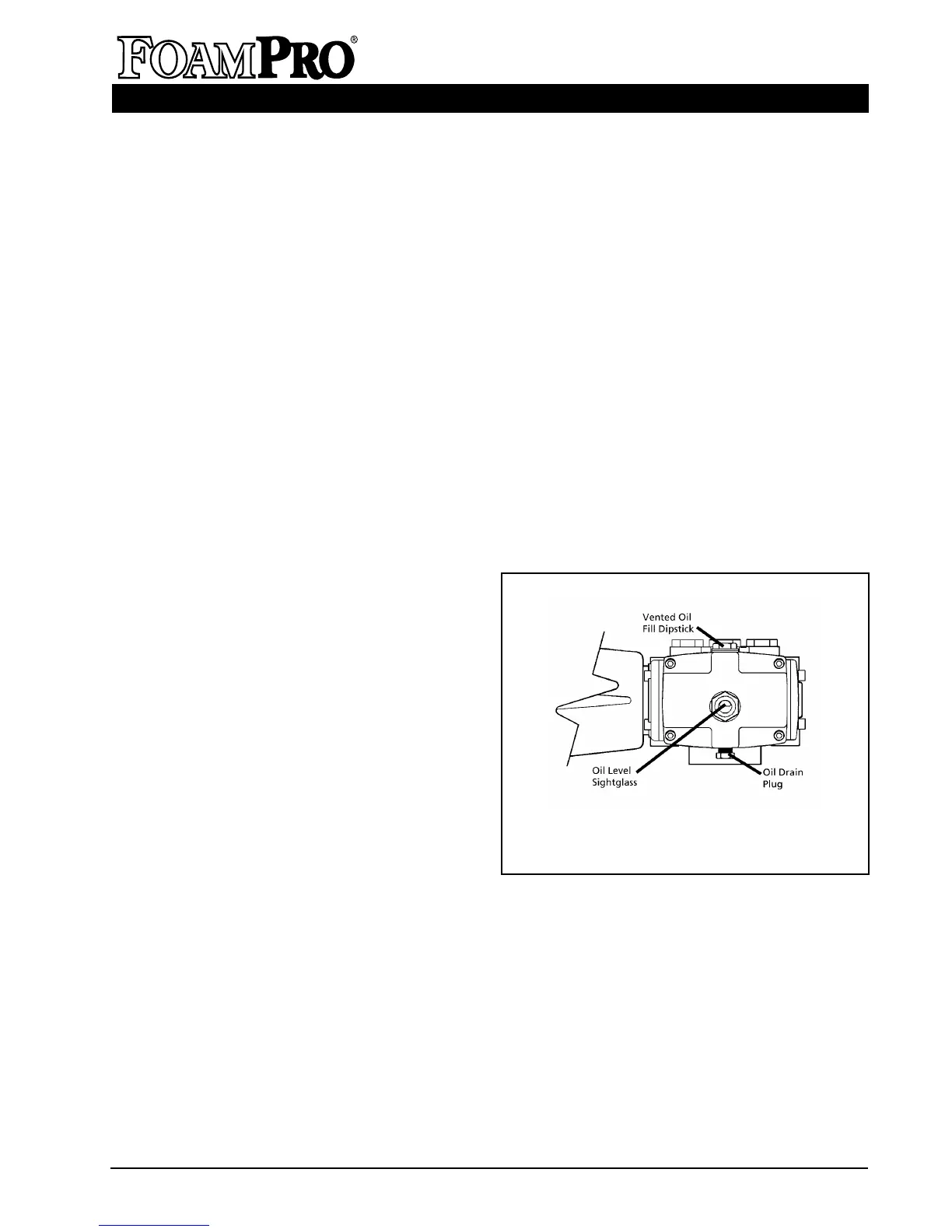

3. Monthly: Check foam pump gear case oil

level and refill as necessary with

SAE 30 weight non-detergent oil.

4. Annually: Drain the pump oil and refill pump

crankcase with SAE 30 weight non-

detergent oil. Check for concentrate or

water in the drain oil.

NOTE: Water quality, flushing & storage

techniques, environment and usage may have

an effect on your maintenance schedule. To

ensure equipment longevity, it is recommended

to adjust your schedule accordingly.

CAUTION: Release all pressure and drain all

concentrate and water from the discharge

system before servicing any of its component

parts.

Figure 27. Foam Pump Oil Level Check

1. Turn the CAL/INJECT valve to the Calibrate

position.

2. With the fire pump flowing water from foam

discharge and the FoamPro on observe the

hose from the CAL/INJECT valve.

3. When foam concentrate flows from the unit

turn the CAL/INJECT valve back to the

INJECT position. The pump is now primed

and ready for normal operation.

4. If the fire pump is not running, place the

FoamPro into the simulated flow mode and

proceed with above steps.

11

Loading...

Loading...