22

Installation and Operation Manual

SystemsSystems

2001 and 2002

If you are still having difficulty priming the foam

pump in your FoamPro system, do the

following:

• Make sure foam concentrate tank shutoff

valve is open.

• Check to make sure there are no restrictions

from the concentrate tank to the inlet of the

foam pump.

• Check to make sure there are no leaks in

the plumbing where air can enter the pump.

Wet the foam pump to speed priming operations

using the following procedures.

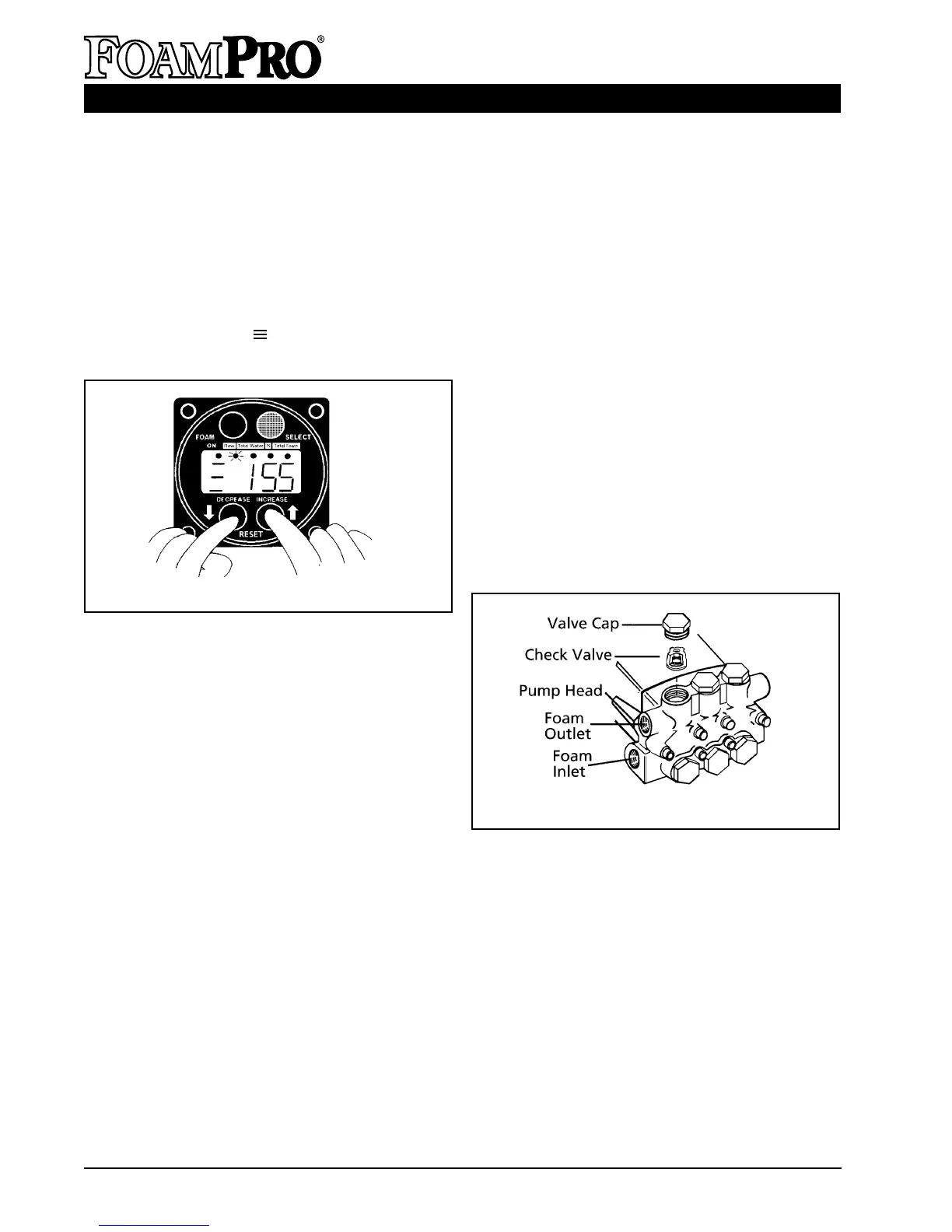

• Remove one of the valve caps from the

head of the pump and remove the check

valve under it (see Figure 23).

• Pour a small amount of concentrate into the

valve opening to fill up the pumping

chamber in the pump head.

• Replace the check valve and cap and

tighten securely. Run the pump again and

the pump should prime right away.

Proceed to calibration section as the system

must be calibrated.

Figure 23. Foam Pump Manual Priming

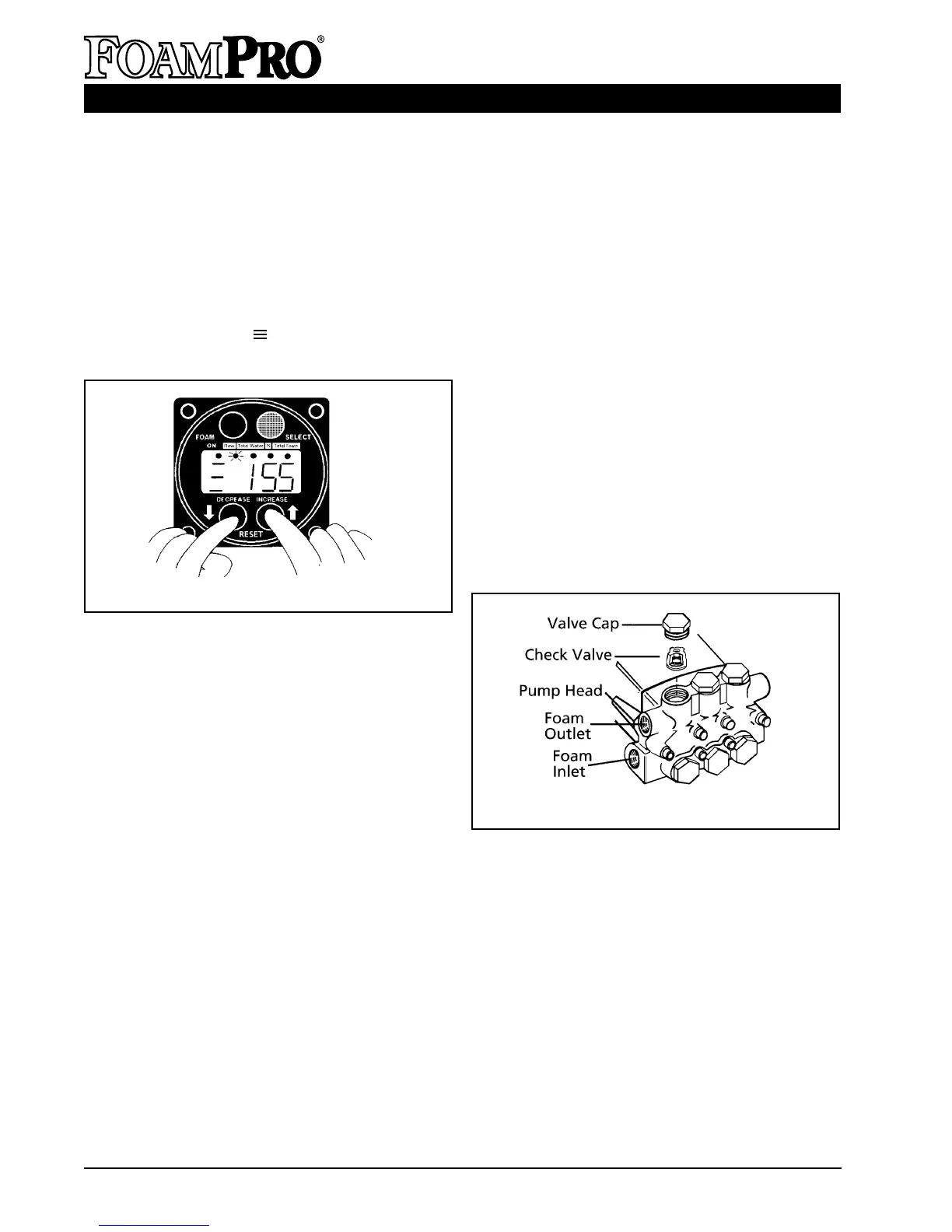

Figure 22. Simulated Flow Indication

➯

➯

➯

collect the output that will be coming from the

foam pump.

• Put the system into “simulated flow mode”

by selecting the “FLOW” display and

depressing "RESET" (both up and down

buttons simultaneously) (See Figure 22).

Increase simulated flow by pressing

button to permit easier priming (above 150).

Display will show “ ” to indicate the

simulated flow.

• Engage the FoamPro system by pressing

the red “FOAM" button.

• Foam concentrate should begin flowing into

the container. If concentrate is not being

pumped, check first to make sure the foam

pump is running. If the pump is running, but

no concentrate is being delivered, then the

pump is most likely not primed completely.

If the pump does not prime within 20-30

seconds, disengage the system by pressing

the red “FOAM” button.

• If the system has been installed properly,

foam concentrate should flow readily to the

pump.

• Once foam flow is established, turn the

system off and turn the CAL/INJECT valve

back to the inject position.

Loading...

Loading...