24

Installation and Operation Manual

SystemsSystems

2001 and 2002

SYSTEM RESET

During calibration procedures, it may be

necessary to return the system to the original

factory default settings. To return to the factory

default values, enter calibration and setup mode

as previously described. Immediately after

entry into calibration and setup mode, prior to

pressing any other button, depress the and

simultaneously. This action will return the

system to the factory default settings. Proceed

with calibration and setup after performing this reset.

NOTE: If using the Dual Tank Option on the

controller and Reset is used, the Dual Tank

default will need to be reconfigured.

FLOWMETER CALIBRATION

NOTE: It is critical that an accurate flow

measuring device be used to measure the

water flow to calibrate the flowmeter(s). Use a

suitable size smooth bore nozzle and an

accurate Pitot Gauge instrument. Hand held

pitot gauges are usually not very accurate. At

the first available opportunity make sure the

system is calibrated with an accurate flow

measuring device. Determine the water flow

normally expected from that flowmeter

discharge outlet. For example, actually

establish a flow of 150 gpm [568 L/min.] of

water through a nozzle and Pitot system.

Enter Calibration and Setup mode using the

method previously described. Press the

"SELECT" button and illuminate the light under

“FLOW”. The current water flow rate will be

displayed. Press the or button to set the

reading to match the actual flow calculated from

the Pitot gauge reading. Decrease fire pump

pressure by approximately 1/2 and recalculate

water flow rate. Verify that reading on the

Digital Display Control Module is the same as

the calculated value. Stop the water flow when

the reading adjustments are completed.

To lock the settings, exit Calibration and Setup

mode by depressing and releasing the switch

inside the cover screw opening. The display will

show a zero until any function button is pressed.

SIMULATED FLOW

The default Simulated Flow value should be

adjusted while operating in Calibration and

Setup mode. Enter Calibration and Setup Mode

using the method previously described. Press

the SELECT button until the light under FLOW

is illuminated. Pressing both the and

buttons simultaneously will display the

default simulated flow reading. Adjust the

setting by pressing the or buttons to set

the desired rate, i.e., “ 100”. After the rate has

been set, press the and buttons

simultaneously again to return to Calibration

and Setup mode.

This setting will remain in the computer memory

and be the default rate for all future Simulated

Flow operations.

Exit Calibration and Setup mode as previously

described.

FOAM CONCENTRATE INJECTION RATE

When power is supplied to the FoamPro

system, the foam concentrate injection rate in

memory will be the default injection rate setting.

The default concentrate injection rate can be

adjusted by entering Calibration and Setup

mode as previously described.

Use the SELECT button to illuminate the lamp

below “%”. The display will show the current

default concentrate injection rate stored in the

computer memory as “

PC x.x

”. The or

buttons can be used to set the desired

concentrate injection rate. Set this rate to the

foam concentrate injection rate used most

frequently in operation.

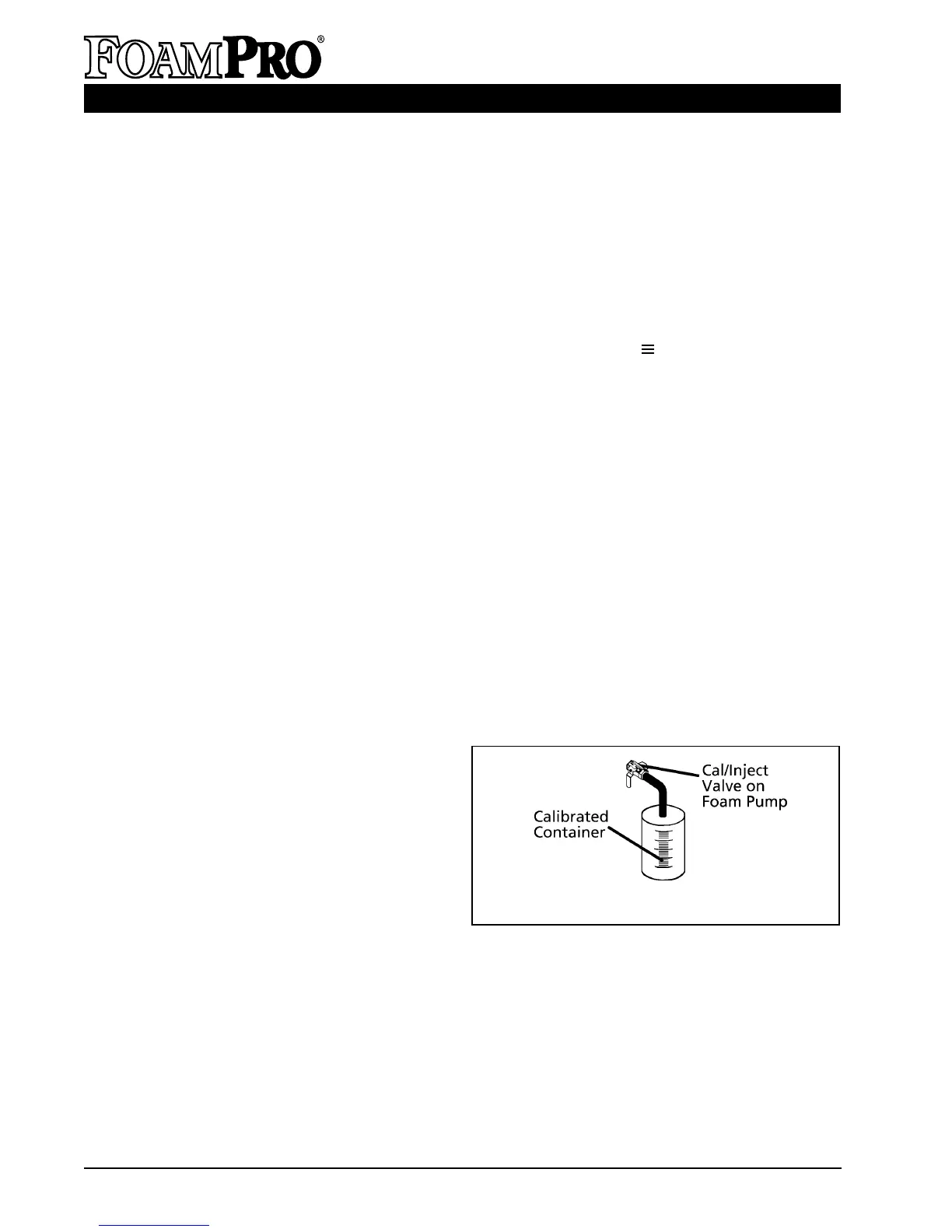

Figure 25. Foam Concentrate Collection

➯

➯

➯

➯

➯

➯

➯

➯

➯

➯

➯

➯

Loading...

Loading...