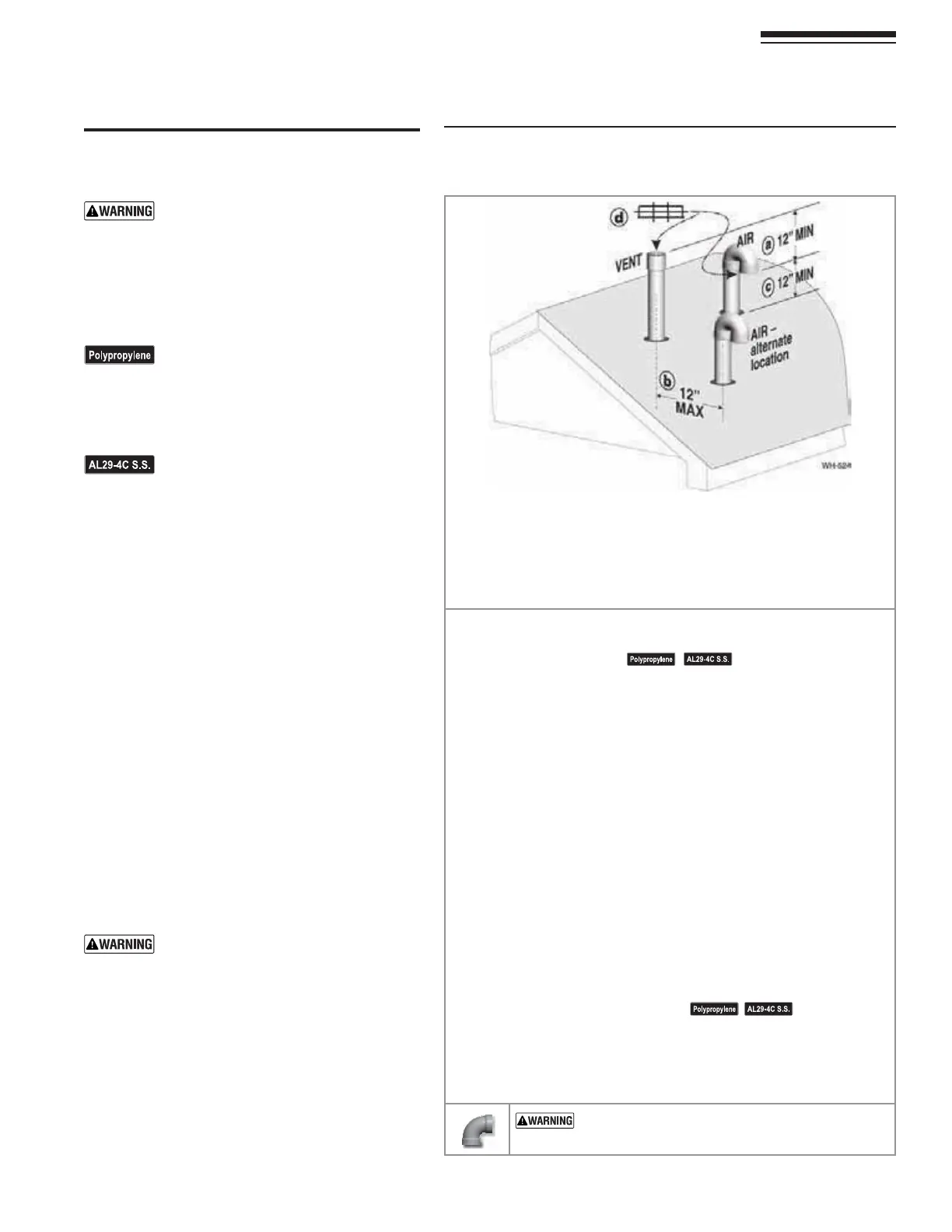

Figure 30 3EPARATEPIPESVERTICALTERMINATION

4ERMINATEVENTANDAIRPIPESSUCHTHAT

A !)2).4!+%)3!4,%!34INCHESBELOWVENTOUTLET

B !)2).4!+%IS NO FURTHER than 12 inches away center to center

C !)2 ).4!+% )3 !4 ,%!34 INCHESABOVEROOF OR SNOW LINE

KEEPVENTSAIRINTAKEAREACLEAROFACCUMULATINGSNOW

D 6ENTANDAIRTERMINATIONSARElTTEDWITHBIRDSCREENS

3TEP 2EADANDFOLLOWALLINSTRUCTIONSINTHISMANUAL$/./4PROCEED

WITH VENTAIR INSTALLATION UNTIL YOU HAVE READ PAGE

THROUGHPAGE

3EENOTICESATLEFT

3TEP )NSTALLTHEBOILERINALOCATIONTHATALLOWSPROPERROUTINGOFALLVENT

and air piping to the selected sidewall location.

3TEP -AKESURETHE SELECTEDVERTICAL TERMINATION LOCATION COMPLIESWITH

&IGUREPAGE-ULTIPLEBOILERTERMINATIONSMUSTALSOCOMPLY

with Figure 31, page 28.)

3TEP Use only the vent materials listed in Figure 21, page 19. Provide pipe

adapters where required. Vent piping and air piping lengths must not

exceed the values shown in Figure 20, page 18.

3TEP Prepare the vertical penetrations and secure penetration components as

INSTRUCTEDINTHISSECTION3EEh0REPAREROOFPENETRATIONSvON page 28

and “Termination and fittings” on page 28.

3TEP The air piping must terminate in a 180-degree return bend or down-

turned elbow as shown above. The vent piping must terminate in a

COUPLINGPOINTEDUPWARD as shown above.

3TEP Install vent and air piping between the boiler and the vertical termina-

tions. Slope horizontal piping downward toward the boiler at least 1/4

INCHPERFOOT)NSTALLPIPESUPPORTSEVERYFEETONBOTHTHEHORIZONTAL

ANDVERTICALRUNS)NSTALLAHANGERSUPPORTWITHININCHESOFANYUPTURN

in the piping. See page 32FORGENERALGUIDELINES!LSOCOMPLYWITHVENT

PIPEMANUFACTURERSINSTRUCTIONS

3EENOTICESATLEFT

3TEP Insert the vent and air piping through the vertical penetrations and

secure the termination fittings.

3TEP -AINTAINCLEARANCESSHOWNABOVE6ENTANDAIRTERMINATIONSMUSTBE

fitted with a bird screen as shown.

53% 37%%0 %,"/73 &/2 !,,6%.4 !.$ !)2

0)0).'$/./4USESHORTRADIUSELBOWSFORVENTOR

AIRPIPING"OILERPERFORMANCECOULDBEAFFECTED

Part number 550-142-850/0716

27

FreeStyle

®

WALL MOUNT GAS-FIRED WATER BOILER — Boiler Manual

Allowable vent/air pipe materials

& lengths

Use only the vent materials and kits listed

in Figure 21, page 19. Provide pipe adapt-

ERSIFSPECIlED

1. Locate the terminations such that the total air piping

ANDVENTPIPINGFROMTHEBOILERTOTHETERMINATION

will not exceed the maximum length given in Fig-

ure 19, page 19.

For polypropylene applications, comply

with any additional requirements in the

VENTSYSTEMMANUFACTURERSINSTRUCTIONS

(Do Not use 3” PVC transition pieces

at the boiler vent and air connections).

Install a locking collar at every joint.

&OR!,# VENTPIPE APPLICATIONS

comply with any additional requirements

INTHEVENTSYSTEMMANUFACTURERSINSTRUC-

tions. 0ROVIDE A!,# STARTER PIECE

FROMTHE!,# MANUFACTURERTOTHE

transition piece at the boiler vent con-

nection. The air piping must be PVC or

CPVC. Provide a 3” PVC transition piece

ATTHEBOILERAIRCONNECTIONIFUSINGvAIR

piping.

$ETERMINETERMINATIONLOCATION

1. The air and vent terminations must be installed as

shown in Figure 30.

2. The terminations must comply with clearances and

limitations shown in Figure 21, page 22.

3. Locate the terminations so they are not likely to be

DAMAGEDBYFOREIGNOBJECTSSUCHASSTONESORBALLS

ORSUBJECTTOBUILDUPOFLEAVESORSEDIMENT

-ULTIPLEVENTAIRTERMINATIONS

1. When terminating multiple boilers, terminate each

vent/air connection as described in this manual.

Terminate all vent pipes at the same height

and all air pipes at the same height to

AVOIDPOSSIBILITYOFSEVEREPERSONALINJURY

death or substantial property damage.

2. 0LACEROOFPENETRATIONSTOOBTAINMINIMUMCLEAR-

ANCEOFINCHESBETWEENEDGEOFAIRINTAKEELBOW

ANDADJACENTVENTPIPEOFANOTHERBOILERFOR53

installations (see Figure 34, page 31).

3. 4HEAIRINLETOFAFreeStyle®BOILERISPARTOFADIRECT

VENTCONNECTION)TISNOTCLASSIlEDASAFORCEDAIR

INTAKEWITHREGARDTOSPACINGFROMADJACENTBOILER

vents.

12 DIRECT VENT — 6ERTICALWITHSEPARATEPIPES

Loading...

Loading...