Part number 550-142-850/0716

25

FreeStyle

®

WALL MOUNT GAS-FIRED WATER BOILER — Boiler Manual

11 DIRECT VENT — Sidewall concentric

Allowable vent/air pipe materials

& lengths

1. The concentric termination kit must be purchased

separately.

Use only the vent materials and kits listed in

Figure 21, page 19

0ROVIDEPIPEADAPTERSIF

specified.

2. Locate the termination such that the total air pip-

INGANDVENTPIPINGFROMTHEBOILERTOTHETERMINA-

tion will not exceed the maximum length given in

Figure 20, page 18

.

3. This termination requires a 45-degree elbow that is

not supplied with the termination kit. The maximum

VENTAIRPIPELENGTHSINCLUDEALLOWANCEFORTHISELBOW

For polypropylene applications, comply

with any additional requirements in the

VENTSYSTEMMANUFACTURERSINSTRUCTIONS

(Do Not use 3” PVC transition pieces at the

boiler vent and air connections)

and at the

TERMINATIONIFUSING A v 06# CONCENTRIC

vent kit. Install a locking collar at every joint.

&OR!,#VENTPIPEAPPLICATIONSCOMPLY

with any additional requirements in the vent

SYSTEMMANUFACTURERSINSTRUCTIONS

Provide

A!,#STARTERPIECEFROMTHE!,#

MANUFACTURERTOTHE

transition at the boiler

VENTCONNECTION!IRPIPEMUSTBE06#OR

CPVC. Provide a 3” PVC transition at the

BOILERAIR CONNECTIONIFUSING v AIR PIPE

Provide transition pieces to PVC at the vent

and air pipe termination connections.

Wall penetration thickness between 2” to

24”.

$ETERMINETERMINATIONLOCATION

1. The concentric termination kit must be installed as

shown in Figure 29, page 26.

2. The termination must comply with clearances and

limitations shown in

Figure 22, page 21

.

3. Locate the termination so it is not likely to be damaged

BYFOREIGNOBJECTSSUCHASSTONESORBALLSORSUBJECT

TOBUILDUPOFLEAVESORSEDIMENT

-ULTIPLEVENTAIRTERMINATIONS

1. When terminating multiple boilers, install each con-

centric termination as described in this manual.

!LLVENTPIPESANDAIRINLETSMUSTTERMINATE

ATTHE SAME HEIGHT TOAVOIDPOSSIBILITY OF

severe personal injury, death or substantial

property damage.

2. Place wall penetrations to obtain minimum clearance

as shown in Figure 28, page 26FOR53INSTALLATIONS

3. 4HEAIRINLETOFA&REE3TYLE®BOILERISPARTOFADIRECT

VENTCONNECTION)TISNOTCLASSIlEDASAFORCEDAIRIN-

TAKEWITHREGARDTOSPACINGFROMADJACENTBOILERVENTS

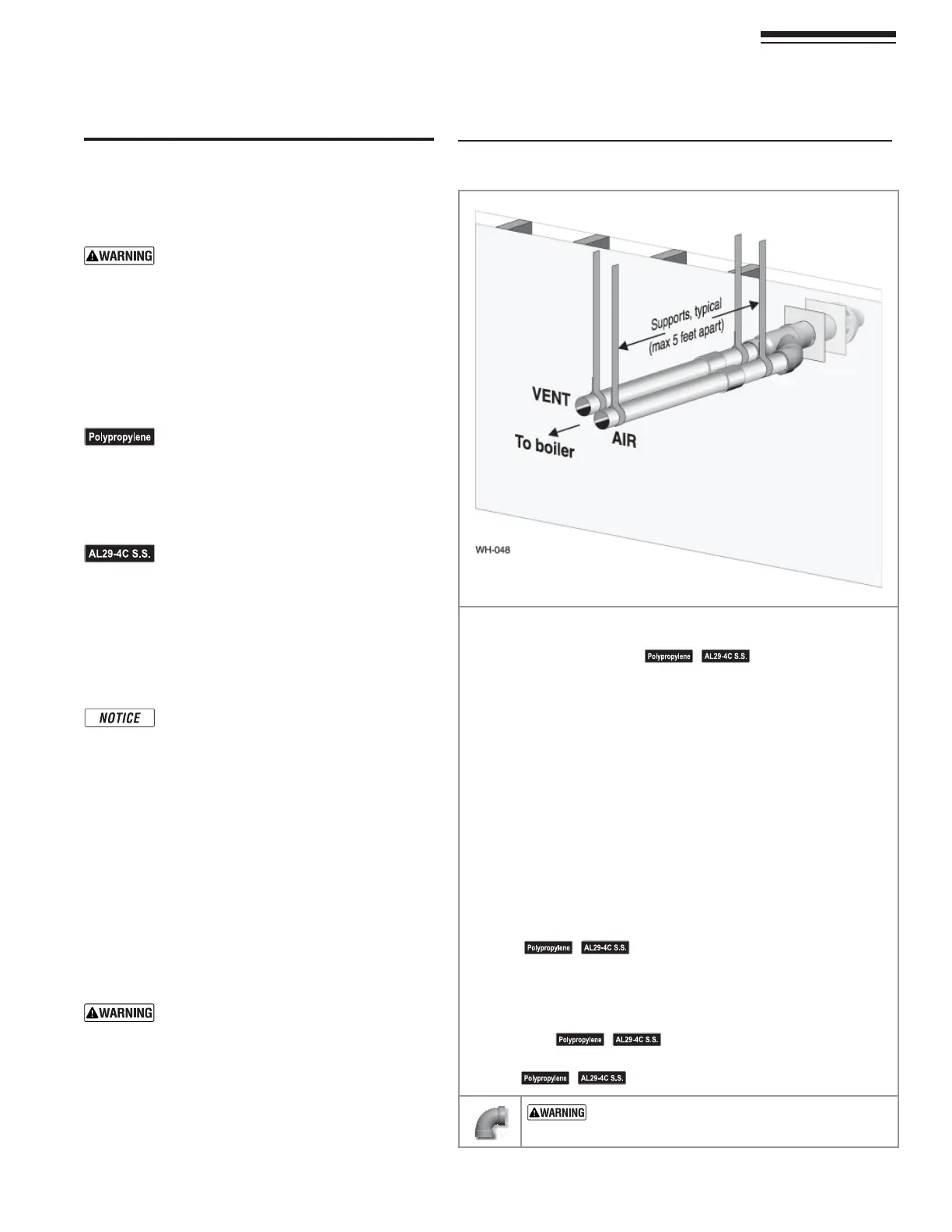

&IGURE ).34!,,!4)/.3%15%.#%#ONCENTRICHORIZONTAL

3TEP 2EADANDFOLLOWALLINSTRUCTIONSINTHISMANUAL$/./4PROCEED

WITH VENTAIR INSTALLATION UNTIL YOU HAVE READ PAGE

THROUGHPAGE

3EENOTICESATLEFT

3TEP )NSTALLTHEBOILERINALOCATIONTHATALLOWSPROPERROUTINGOFALLVENT

and air piping to the selected sidewall location.

3TEP -AKESURETHESELECTEDSIDEWALLTERMINATIONLOCATIONCOMPLIESWITH

Figure 22, page 21-ULTIPLEBOILERCONCENTRICTERMINATIONSMUST

also comply with

Figure 28, page 26

.)

3TEP Use only the vent materials listed in Figure 21, page 19. Provide pipe

adapters where required.

3TEP Vent piping and air piping lengths must not exceed the values shown

in Figure 20, page 18.

3TEP 4HECONCENTRICTERMINATIONMUSTBEASSEMBLEDANDINSTALLEDBEFORE

PIPINGFROMTHEBOILERTOTHETERMINATION

3TEP Prepare the sidewall penetration — assemble the concentric ter-

mination kit and secure the cover plates as instructed in this sec-

tion. Provide the supports indicated and mount the termination

assembly. See “Install termination — concentric pipes” on page 26.

3EENOTICESATLEFT

3TEP Install vent and air piping between the boiler and the concentric

vent/air termination. Slope horizontal piping downward toward the

BOILERATLEASTINCHPERFOOT3EE page 32FORGENERALGUIDELINES

3TEP )NSTALLPIPESUPPORTSEVERYFEETONBOTHTHEHORIZONTALANDVERTICAL

runs.

3EENOTICESATLEFT

3TEP )NSTALLAHANGERSUPPORTWITHININCHESOFANYUPTURNINTHEPIPING

3EENOTICESATLEFT

53%37%%0%,"/73&/2!,,6%.4!.$!)2

0)0).'$/./4USESHORTRADIUSELBOWSFORVENTOR

AIRPIPING"OILERPERFORMANCECOULDBEAFFECTED

Loading...

Loading...