Check inhibitor concentration

annually

1. 4ESTTHEP(OFASAMPLEOFSYSTEMWATERATLEASTANNUALLY

4HEP(OFTHEWATERMIXTUREMUSTBEBETWEENAND

(Or use the Sentinel inhibitor test kit to check concentra-

tion.)

2. )FP(ISOUTSIDETHISRANGEORINHIBITORTESTKITINDICATES

LOWLEVELTHEINHIBITORLEVELMAYNOTBESUFlCIENTTOPRE-

vent corrosion.

3. 4ESTANTIFREEZECONCENTRATION

4EST ANTIFREEZECONCENTRATION AT LEAST ANNUALLY

)FCONCENTRATIONISLOWADDANTIFREEZEORDRAIN

system and refill with correct mixture.

4. &OLLOWINSTRUCTIONSONANTIFREEZECONTAINERTODETERMINE

THEAMOUNTOFANTIFREEZENEEDED

$/./4 exceed 50% by

VOLUMECONCENTRATIONOFANTIFREEZE

#HECKINHIBITORLEVELAFTERADJUSTMENTSAREMADE

Check thermostat circuits

1. Disconnect wires connected to the $(7AND(%!4 ther-

mostat terminals (see Field wiring, beginning on page 50

FORLOWVOLTAGETERMINALLOCATIONSANDAPPLICATIONINFOR-

MATION-ARKTHEWIRESBEFOREREMOVINGTOAVOIDWIRING

errors when re-connecting them.

2. #ONNECTAVOLTMETERACROSSEACHPAIROFINCOMINGWIRES

Close each thermostat, zone valve and relay in the external

circuits one at a time and check the voltmeter reading across

the incoming wires.

3.

4HERESHOULD.%6%2BEAVOLTAGEREADING

4. )FAVOLTAGEDOESOCCURUNDERANYCONDITIONCHECKANDCORRECT

the external wiring.

$/ ./4 CONNECT THE FreeStyle

®

thermostat

terminals to 3-wire zone valves

. This could cause

control damage.

5. Once the external thermostat circuit wiring is checked and

CORRECTEDIFNECESSARYRECONNECTTHEEXTERNALTHERMOSTATCIRCUIT

wires.

Inspect/fill condensate system

)NSPECTCHECKCONDENSATELINESANDlTTINGS

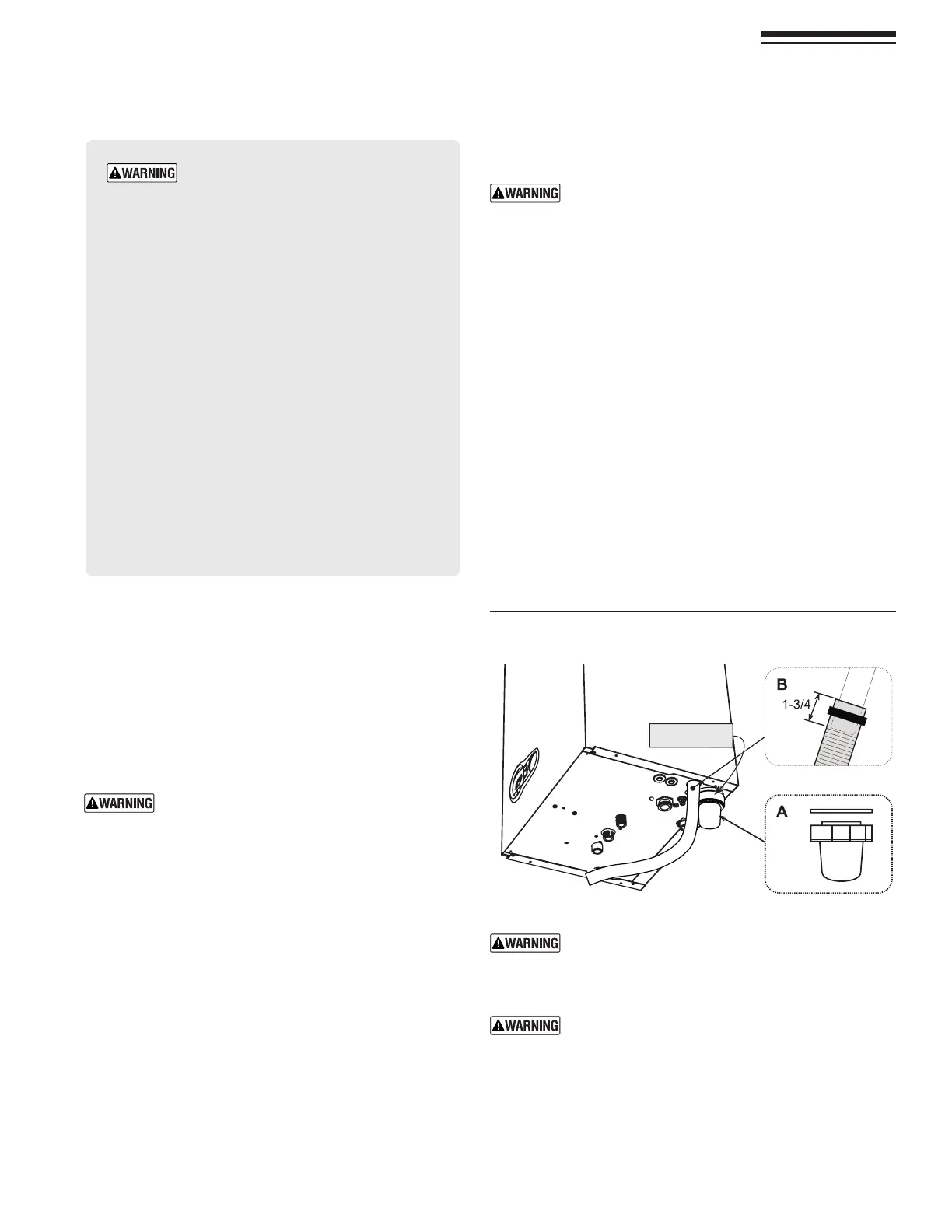

1. Inspect the condensate drain line, condensate PVC fittings and

condensate trap. (See page 47FORCOMPONENTLOCATIONS

&ILLCONDENSATETRAPWITHWATER

1. Loosen the nut that secures the condensate trap body to the

boiler condensate connection (see Figure 94). Pull the trap

DOWNTODISENGAGEFROMHEATEXCHANGER<0ULLTHETRAPBODY

FORWARDENOUGHTOALLOWPOURINGWATERINTOTHETOPOFTHETRAP

2. &ILLTHETRAPWITHFRESHWATERUNTILWATERBEGINSTORUNINTOTHE

condensate drain tube.

3. Reattach the trap body by sliding onto the boiler condensate

outlet, then retightening the trap body nut.

.UT

Figure 94 $ISCONNECTCONDENSATETRAPASSEMBLYTOlLL

TRAPBODYWITHWATER

The condensate trap must be filled with water during

ALLTIMESOFBOILEROPERATIONTOAVOIDmUEGASEMISSION

FROMTHECONDENSATEDRAINLINE&AILURETOlLLTHETRAP

could result in severe personal injury or death.

)FIT IS SUSPECTEDTHATTHECONDENSATEDRAIN CON-

nection is or was blocked, then boiler components

like the gas valve, blower venturi, igniter and heat

EXCHANGERNEEDTOBEINSPECTED#HECKFORDAMAGES

OCCURRINGFROMWATERACCUMULATIONINTHISCABINET

!NYDAMAGED COMPONENTSNEED TO BEREPLACED

Failure to replace water damaged components could

result in severe personal injury or death.

Part number 550-142-850/0716

69

FreeStyle

®

WALL MOUNT GAS-FIRED WATER BOILER — Boiler Manual

28

Check for gas leaks

"EFORESTARTINGTHEBOILERANDDURINGINITIALOPERATION

use a leak detector or smell near the floor and around

THEBOILERFORGASODORANTORANYUNUSUALODOR2EMOVE

BOILERJACKETDOORANDSMELLTHEINTERIOROFTHEBOILER

jacket.

$ONOTPROCEEDWITHSTARTUPIFTHEREISANY

INDICATIONOFAGASLEAK2EPAIRANYLEAKATONCE

.

$/./4ADJUSTORATTEMPTTOMEASUREGASVALVEOUT-

LETPRESSURE.

4HEGASVALVEISFACTORYSETFORTHECORRECT

OUTLETPRESSURE4HISSETTINGISSUITABLEFORNATURALGAS

ANDPROPANEREQUIRINGNOlELDADJUSTMENT!TTEMPTING

to alter or measure the gas valve outlet pressure could

result in damage to the valve, causing potential severe

personal injury, death or substantial property damage.

0ROPANEBOILERSONLY — Your propane supplier mixes

an odorant with the propane to make its presence de-

TECTABLE)NSOMEINSTANCESTHEODORANTCANFADEAND

THEGAS MAY NOLONGERHAVEAN ODOR"EFORESTARTUP

ANDPERIODICALLYTHEREAFTERHAVETHEPROPANESUPPLIER

VERIFYTHECORRECTODORANTLEVELINTHEGAS

Loading...

Loading...