Final checks before lighting the boiler

❏

/PENANYONOFFVALVESBETWEENBOILERANDTHESYSTEMS

❏

6ERIFYTHATTHEREARENOLEAKSOFTHEGASSYSTEM

❏

6ERIFY THAT THEBOILERAND SYSTEM AREFULL OF WATERAND ALL

SYSTEMCOMPONENTSARECORRECTLYSETFOROPERATION

❏

6ERIFYTHATCONDENSATETRAPDRAINLINEISlLLEDWITHWATER

❏

6ERIFYTHATTHEREARENOLEAKSINTHESYSTEM$(7PIPING

connections or boiler.

❏

6ERIFYELECTRICALCONNECTIONSARECORRECTANDSECURELYATTACHED

❏

)NSPECTVENTPIPINGANDAIRPIPINGFORSIGNSOFDETERIORATION

FROMCORROSIONPHYSICALDAMAGEORSAGGING6ERIFYAIRPIP-

ing and vent piping are intact and correctly installed per this

manual.

❏

Read the instructions to adjust and set up the FreeStyle

®

control.

❏

6ERIFYTHATTHEBOILERMODELISSETCORRECTLYINTHEFreeStyle

®

control, and that it displays correctly.

To start the boiler

4HE COMBUSTION FOR THIS BOILER HAS BEEN

CHECKEDADJUSTEDANDPRESETATTHEFACTORY

FOROPERATIONFOR.ATURAL'AS

Having checked:

s That the boiler has been installed in accordance with

these instructions.

s 4HEINTEGRITYOFTHEmUESYSTEMANDTHEmUESEALS

s 4HEINTEGRITYOFTHEBOILERCOMBUSTIONCIRCUITANDTHE

relevant seals.

1. !PPLYPOWERTOTHEBOILER

2. Follow the Operating Instructions, Figure 96, page 71.

Test Mode Operation

0ROCEEDTOPUTTHEBOILERINTOOPERATIONASFOLLOWS

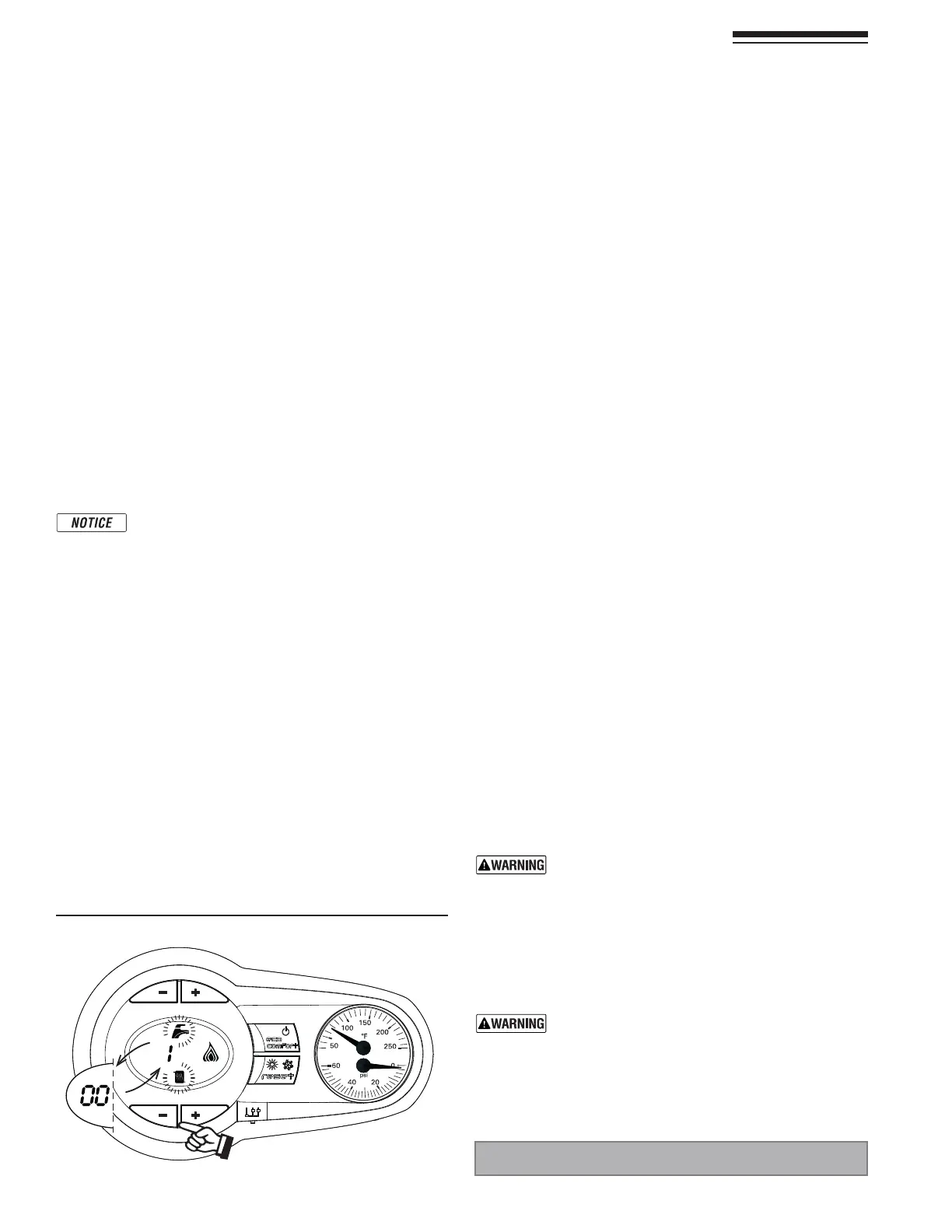

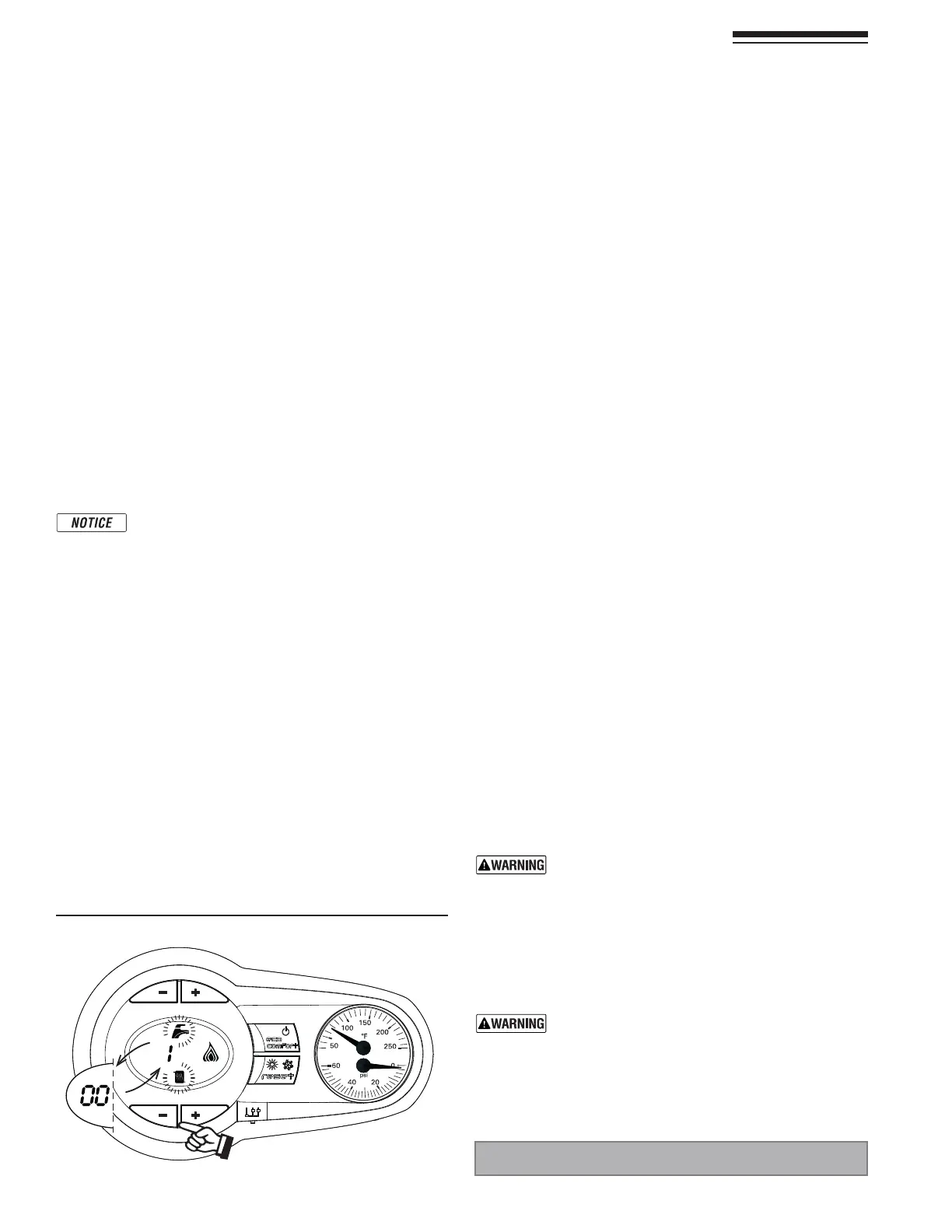

1. To operate the boiler in test mode, press the CH “-” and

“+”KEYSTOGETHERFORSECONDS3EEBELOWTOACTIVATETHE

“4%34” mode.

2. The boiler lights at the maximum heating 100% rate dis-

played on the LCD display.

Figure 95 #ONTROLIN4EST-ODE

3. The high fire (large) flame symbol will be displayed once the

boiler has lit.

4. Use DHW “-” button to drop firing rate to low fire.

5. To exit the “4%34” mode, press the CH keys (Items 3 and

4 Figure 74, page 60TOGETHERFORSECONDS ORLEAVETHE

BOILERTOAUTOMATICALLYSWITCHOFFAFTERMINUTESORSTOP-

ping DHW flow.

6. This TEST procedure is used to check/adjust combustion

CO and CO

2

PERSPECIFICATIONS Figure 98, page 73 and

Figure 101, page 74.

If boiler does not start correctly

1. #HECK FOR LOOSE CONNECTIONS BLOWN FUSE OR IS BOILER .OT

plugged in?

2. !REEXTERNALLIMIT CONTROLSIF USED OPEN )SBOILER WATER

temperature above 200°F?

3. !RETHERMOSTATSSETBELOWROOMTEMPERATURE

4. Is gas turned on at meter and boiler?

5. Is incoming gas pressure less than the minimum values given

on page 16?

6. !REFreeStyle®CONTROLSETTINGSCORRECTFORTHEAPPLICATION

7. )FNONEOFTHEABOVECORRECTSTHEPROBLEMREFERTO4ROUBLE-

shooting, beginning on page 81.

❏ Check system and boiler

❏#HECKWATERPIPING

1. #HECKSYSTEMPIPINGFORLEAKS)FFOUNDSHUTDOWNBOILERAND

REPAIRIMMEDIATELY3EE7!2.).'ONpage 67 regarding

FAILURETOREPAIRLEAKS

2. 6ENTANYREMAININGAIRFROMSYSTEMUSINGMANUALVENTS!IR

INTHESYSTEMWILLINTERFEREWITHCIRCULATIONANDCAUSEHEAT

distribution problems and noise.

❏#HECKVENTPIPINGANDAIRPIPING

1. #HECKFORGASTIGHTSEALATEVERYCONNECTIONANDSEAMOFAIR

piping and vent piping.

Venting system must be sealed gas-tight to prevent

flue gas spillage and carbon monoxide emissions

which will result in severe personal injury or death.

❏#HECKGASPIPING

1. #HECKAROUNDTHEBOILERANDINSIDETHEBOILERJACKETFORGAS

ODORFOLLOWINGTHEINSTRUCTIONSIN“Warning”on page 48OF

this manual.

IF YOUDISCOVEREVIDENCE OFANYGASLEAKSHUT

down the boiler at once. Find the leak source

with bubble test and repair immediately. Do

not start boiler again until corrected. Failure

to comply could result in severe personal in-

jury, death or substantial property damage.

Part number 550-142-850/0716

70

FreeStyle

®

WALL MOUNT GAS-FIRED WATER BOILER — Boiler Manual

28 (continued)

CONTINUED AFTER NEXT PAGE

Loading...

Loading...