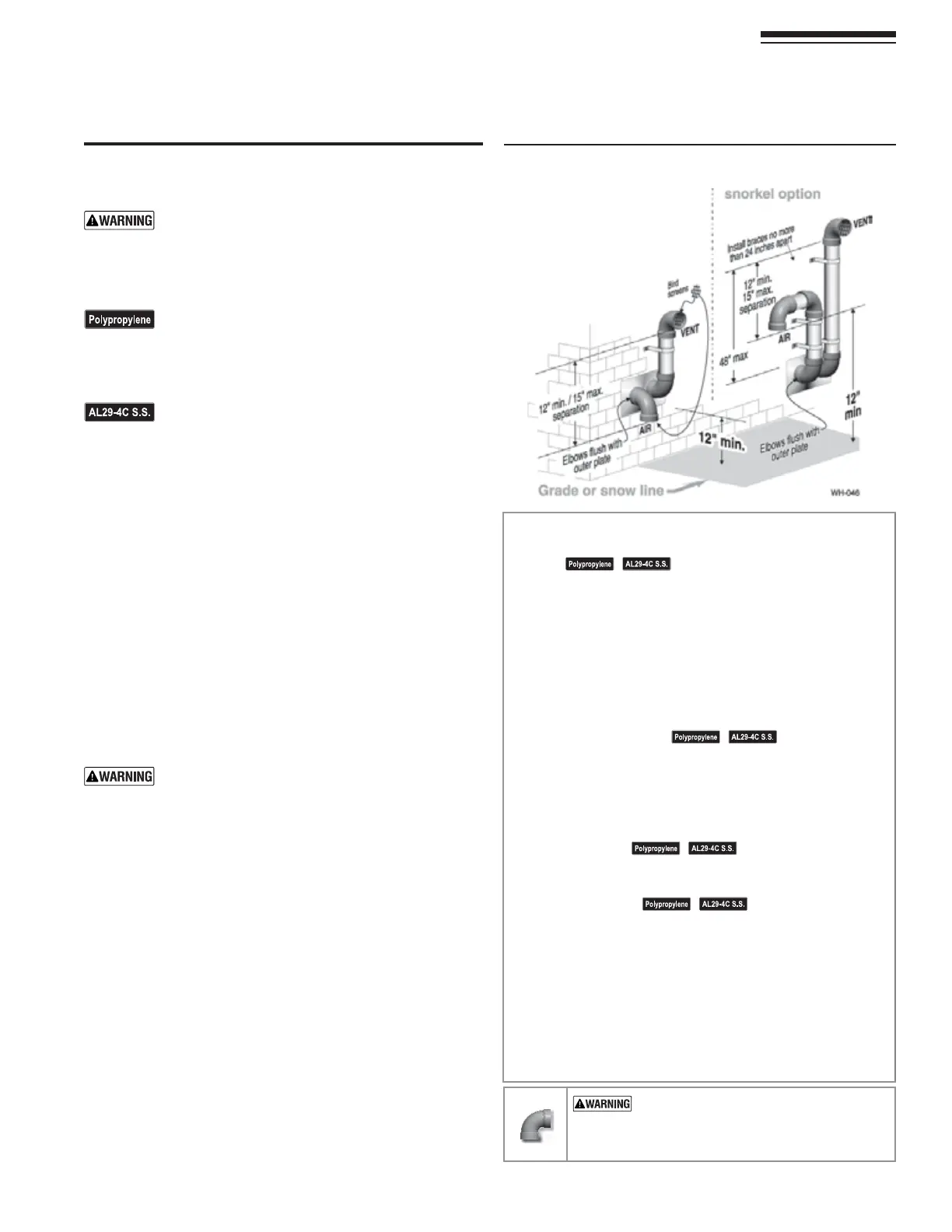

Figure 24 ).34!,,!4)/.3%15%.#%3EPARATEPIPES

SIDEWALL

Part number 550-142-850/0716

23

FreeStyle

®

WALL MOUNT GAS-FIRED WATER BOILER — Boiler Manual

10 DIRECT VENT — Sidewall with separate pipes

Allowable vent/air pipe materials &

lengths

Use only the vent materials and kits listed in

Figure 21, page 190ROVIDEPIPEADAPTERSIFSPECIlED

1. Locate the termination such that the total air piping and vent

PIPINGFROMTHEBOILERTOTHETERMINATIONWILLNOTEXCEEDTHE

maximum length given in Figure 20, page 18.

For polypropylene applications, comply with any

ADDITIONALREQUIREMENTSINTHEVENTSYSTEMMANUFAC-

TURERSINSTRUCTIONS$O.OTUSEv06#TRANSITION

pieces at the boiler vent and air connections). Install

a locking collar at every joint.

&OR!,#VENTPIPEAPPLICATIONSCOMPLYWITH

any additional requirements in the vent system

MANUFACTURERS INSTRUCTIONS 0ROVIDE A!,#

STARTERPIECEFROMTHE!,#MANUFACTURERFORTHE

transition piece at the boiler vent connection. The

air piping must be PVC or CPVC. Provide a 3” PVC

TRANSITIONPIECEATTHEBOILERAIRCONNECTIONIFUSING

2” air piping.

$ETERMINETERMINATIONLOCATION

1. Wall penetration thickness between 2” to 24”.

2. The air and vent terminations must be installed as shown in

Figure 24, page 23 and Figure 26, page 24.

3. The terminations must comply with clearances and limitations

shown in Figure 22, page 21.

4. Locate the terminations so they are not likely to be damaged

BYFOREIGNOBJECTSSUCHASSTONESORBALLSORSUBJECTTOBUILDUP

OFLEAVESORSEDIMENT

5. 6ENT ANDAIRLOCATIONSCANBE ON DIFFERENT BUILDING WALLS

Example: Vent/exhaust can be on North building wall and air

INTAKECANBEON3OUTHBUILDINGWALL$IFFERENTPRESSUREZONE

$ONOTEXCEEDTHEMAXIMUMLENGTHSOFTHEOUTSIDE

vent piping shown in Figure 24. Excessive length

EXPOSEDTO THEOUTSIDECOULDCAUSE FREEZINGOF

condensate in the vent pipe, resulting in potential

boiler shutdown. In extremely cold climates, install

an insulated chase around the vent piping, particu-

LARLYIFUSINGLONGERLENGTHS4HECHASEMUSTALLOW

FORINSPECTIONOFTHEVENTPIPEANDINSULATIONMUST

BEPROTECTEDFROMWATER

-ULTIPLEVENTAIRTERMINATIONS

1. When terminating multiple boilers, terminate each vent/air

connection as described in this manual.

2. Place wall penetrations to obtain minimum clearances shown

in Figure 24FOR53INSTALLATIONS

3. 4HEAIRINLETOFAFreeStyle®BOILERISPARTOFADIRECTVENTCON-

NECTION)TISNOTCLASSIlEDASAFORCEDAIRINTAKEWITHREGARDTO

SPACINGFROMADJACENTBOILERVENTS

0REPAREWALLPENETRATIONS

1. !IRPIPEPENETRATION

A #UTAHOLEFORTHEAIRPIPE3IZETHEAIRPIPEHOLEASCLOSEAS

desired to the air pipe outside diameter.

2. Vent pipe penetration:

3TEP 2EAD AND FOLLOWALL INSTRUCTIONS IN THIS MANUAL

$/ ./4 PROCEED WITH VENTAIR INSTALLATION

UNTIL YOU HAVE READ PAGE THROUGH PAGE

3EENOTICESATLEFT

3TEP Install the boiler in a location that allows proper routing

OFALLVENTANDAIRPIPINGTOTHESELECTEDSIDEWALLLOCATION

3TEP -AKESURETHESELECTEDSIDEWALLTERMINATIONLOCATIONCOM-

plies with Figure 22, page 21-ULTIPLEBOILERSIDEWALLPLATES

must also comply with Figure 25, page 24.)

3TEP Use only the vent materials listed in Figure 21, page 19.

Provide pipe adapters where required. Vent piping and

air piping lengths must not exceed the values shown in

Figure 20, page 18.

3TEP Prepare the sidewall penetrations and secure the sidewall

plates as instructed in this section. See “Prepare wall penetra-

tions” on page 23.

3EENOTICESATLEFT

3TEP The air piping must terminate in a down-turned elbow as

shown above. The vent piping must terminate in an elbow

POINTEDOUTWARDORAWAYFROMTHEAIRINLET as shown

above. See illustration above.

3TEP Install vent and air piping between the boiler and the side-

wall openings. Slope horizontal piping downward toward

THEBOILERATLEASTINCHPERFOOT3EE page 32FORGENERAL

guidelines.

3EENOTICESATLEFT

3TEP )NSTALLPIPESUPPORTSEVERYFEETONBOTHTHEHORIZONTAL

and vertical runs. Install a hanger support within 6 inches

OFANYUPTURNINTHEPIPINGORPERVENTPIPEMANUFACTURERS

instructions.

3EENOTICESATLEFT

3TEP !TTACHTHEVENTTERMINATIONEXTERIORPIPING5SEEITHEROFTHE

configurations shown above, as needed to ensure clearance

above grade or snow line. Keep vents/air intake area clear

OFACCUMULATINGSNOW

3TEP 4HEVENTANDAIRPIPESMAYRUNUPASHIGHASFEETWITH

no enclosure. The vent and air pipes must be secured with

braces, and all clearances and lengths must be maintained.

3PACEBRACESNOFURTHERTHANINCHESAPART

3TEP %XTERNALVENTINGGREATERTHANFEETREQUIRESANINSULATED

enclosure around the vent and air pipes. The vent and air

terminations must exit through the enclosure as shown in

the illustration above, maintaining all required clearances.

53% 37%%0 %,"/73 &/2 !,,6%.4

!.$!)20)0).' — DO NOT use short radius

ELBOWSFORVENTORAIRPIPING"OILERPERFORMANCE

COULDBEAFFECTED

Loading...

Loading...