Part number 550-142-850/0716

37

FreeStyle

®

WALL MOUNT GAS-FIRED WATER BOILER — Boiler Manual

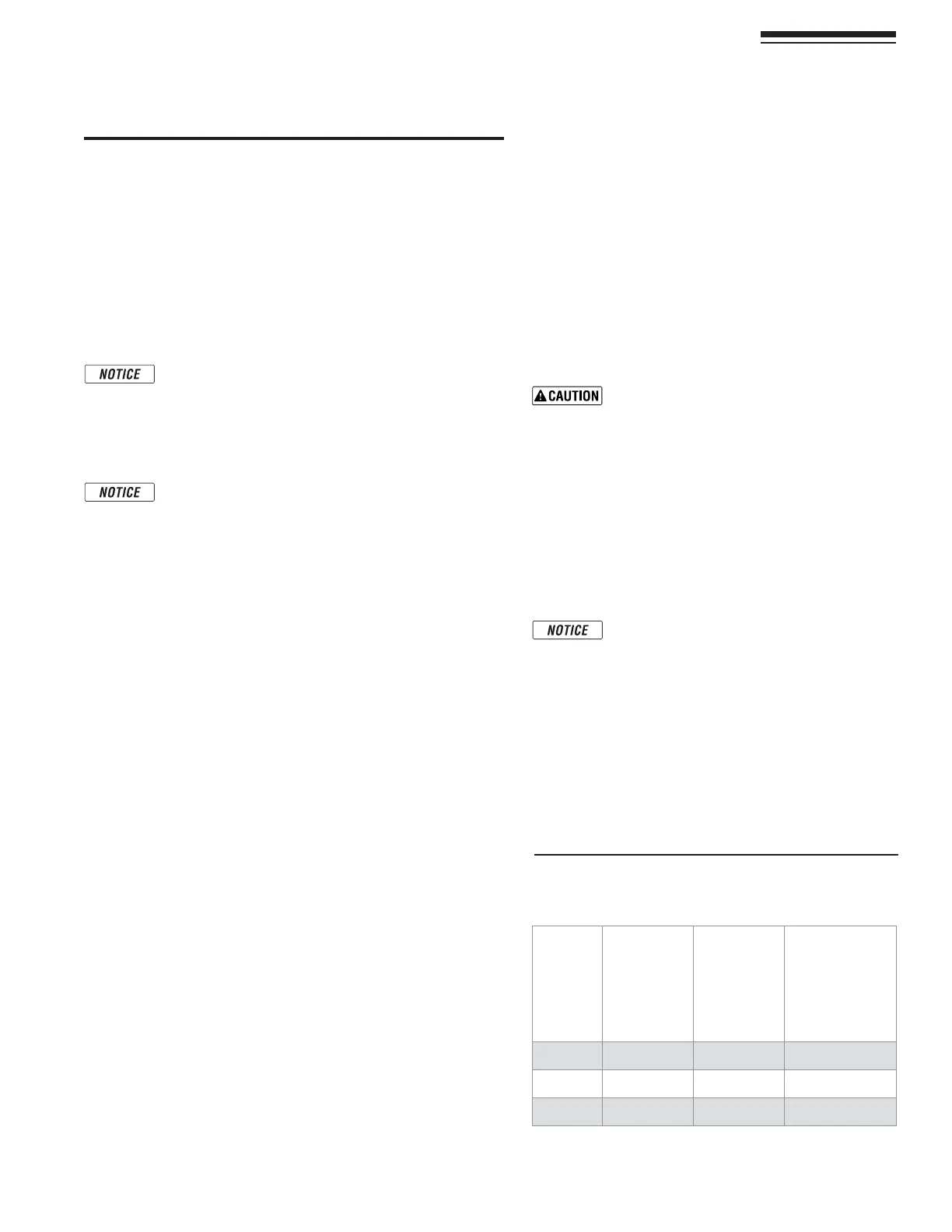

Figure 44 -AXIMUMANDMINIMUMmOWRATESTHROUGH

BOILERHEATEXCHANGER

Boiler

Model

MAX

Flow Rate

20° F

temperature

rise

'0-

MIN

Flow Rate

50° F

temperature

rise

'0-

Flow Rate

Delta T1

protection

67° F

temperature

rise

'0-

&3

7.9 2.9 2.3

&3

12.0 4.3 3.4

&3

15.2 6.1 4.5

17 Primary/Secondary System Piping

System water piping methods

.EARBOILERPIPING

1. Connect boiler to system only as shown in Figure 45, page 38.

The primary/secondary piping shown ensures the boiler loop

WILLHAVESUFlCIENTmOW

2. 3ELECTABOILER LOOP TEMPERATURERISEFROMFigure 47, page 39.

The table indicates the flow and head loss characteristics at that

TEMPERATURERISEANDSUGGESTSPOTENTIALSPEED#IRCULATORSOFOTHER

BRANDSNOTLISTED7ILO!RMSTRONG"'AREACCEPTABLEIFTHEY

MEETTHEmOWANDHEADREQUIREMENTSOFTHEDESIGN

6ERIFY THATTHEboiler loop piping matches closely

with the listed criteria in the NOTICEBELOW)FNEAR

BOILERPIPINGISDIFFERENTCALCULATEHEADLOSSSEPARATELY

USINGHEATEXCHANGERPRESSUREDROPINFORMATIONFROM

Figure 47, page 39 and match to an appropriate pump

speed.

4HEPRESSUREDROPSSHOWNAREFORNEARBOILERPIPINGAS

illustrated in Figure 46, page 38 WITHFEETOFSTRAIGHT

piping. System circulators and zone circulators

3. Install a system circulator or zone circulators as shown in the

piping diagrams in the Primary/Secondary System Piping section

in this manual. These circulators must be supplied by the installer.

3YSTEMORZONECIRCULATORSmOWRATES

1. Size circulators based on the flow rate required to achieve the

temperature drop required. You can closely estimate temperature

RISEORDROPTHROUGHACIRCUITBYUSINGTHEFOLLOWINGFORMULA

where TD is temperature rise (or drop), FLOW is flow rate (in

GPMAND"45(ISTHEHEATLOADFORTHECIRCUIT

FLOW =

"45(

nnnn

4$X

%XAMPLES:

1. #ONSIDERASYSTEMLOOPFORASYSTEMWITHTOTALHEATINGLOADEQUAL

to 210,000 Btuh. The desired temperature drop through the system

piping is 20°F. Then the required flow rate is:

FLOW =

nnnn

X

= GPM

3)-0,)&)%$

&ORTEMPERATUREDROP&,/7-"(

3YSTEMORZONECIRCULATORHEADREQUIREMENT

1. 4HECIRCULATORMUSTBECAPABLEOFDELIVERINGTHEREQUIREDmOW

against the head loss that will occur in the piping.

2. Determine the pipe size needed and the resultant head loss

using accepted engineering methods. See Figure 46, page 38FOR

the head loss through the boiler.

Expansion Tank Location

Figure 45, page 38SHOWTYPICALINSTALLATIONOFTHESYSTEM

expansion tank. It is highly recommended that you locate

the air separator and expansion tank as shown in the sug-

gested piping drawings on pages 37 - 39.

Ensure that the expansion tank size will handle boiler and

SYSTEMWATERVOLUMEANDTEMPERATURE3EETANKMANUFAC-

TURERSINSTRUCTIONSANDRATINGSFORDETAILS!DDITIONALTANKS

MAYBEADDEDTOTHESYSTEMIFNEEDEDTOHANDLETHEEXPAN-

sion. These tanks may be installed by connecting to tees in

the system piping.

Undersized expansion tanks cause system

WATERTOBELOST FROM THERELIEF VALVEAND

makeup water to be added through the fill

VALVE %VENTUALBOILER FAILURECAN RESULTDUE

TOEXCESSIVEMAKEUPWATERADDITION!LWAYS

locate the cold-water fill connection at the

expansion tank. Never locate this elsewhere.

Diaphragm- or bladder-type tank:

2EFERTOFigure 45FORSUGGESTEDPIPINGWHENUSINGADIA-

phragm- or bladder-type expansion tank.

Diaphragm- or bladder-type expansion

tank—Always check pressure and charge

tank with tank removed from system to be

sure reading is accurate. Boiler relief valve is

set for 30 PSIG./PERATINGPRESSUREOFSYSTEM

AFTERTEMPERATURE EXPANSIONABOVECOLDlLL

pressure, should not exceed 24 PSIG to avoid

WEEPINGOFRELIEFVALVE

)NSTALLANAUTOMATICAIRVENTONTOPOFTHEAIRSEPARATORPER

SEPARATORMANUFACTURERSINSTRUCTIONS

Loading...

Loading...