Freeze protection (if used)

Follow these guidelines to prevent pos-

SIBILITYOFSEVEREPERSONALINJURYDEATH

or substantial property damage:

5SE ONLY THE PRODUCTS LISTED BY

7ILLIAMSON4HERMOmOFORUSEWITH

THISBOILER3EEPAGE for infor-

mation.

4HOROUGHLYmUSHANYSYSTEMTHAT

HASUSEDGLYCOL

BEFOREINSTALLINGTHE

new

FreeStyle

®

boiler.

2EVIEW THE MATERIAL SAFETY DATA

SHEETS -3$3

are available online.

4HE-3$3CONTAINSINFORMATIONONPO-

tential hazards and first aid procedures

FOREXPOSUREORINGESTION

#HECKANTIFREEZEINHIBITORLEVELAT

least annually

. Glycol concentration

and inhibitor levels may change over

TIME!DDANTIFREEZETOINCREASE CON-

CENTRATIONIFNECESSARY!DDINHIBITOR

as needed to bring to acceptable level,

USINGINHIBITORTESTKITTOVERIFY

)NADDITIONTOANTIFREEZEANDINHIBITOR

USEAND MAINTAIN MINIMUMLEVELOF

Sentinel X100 inhibitor as directed on

this page.

)F USING FREEZEPROTECTIONFLUID WITH

automatic fill,

install a water meter to

MONITORWATERMAKEUP

. Freeze pro-

TECTIONmUIDMAYLEAKBEFORETHEWATER

begins to leak, causing concentration

TODROPREDUCINGTHEFREEZEPROTECTION

level.

$/ ./4EXCEED ANTIFREEZE

by volume

!NTIFREEZEMOVESMORE

SLUGGISHLYTHANWATERANDCANINTERFERE

WITHHEATTRANSFER!TANTIFREEZECONCEN-

trations higher than 50%, sludge can

develop in the boiler, potentially causing

damage to the heat exchanger.

Clean the system before filling.

!LWAYSDRAIN AND FLUSHTHESYSTEM

THOROUGHLYBEFORElLLINGWITHANTIFREEZE

Sludge, iron oxide deposits and other

sediment in the system inhibit flow and

CANCAUSE RAPIDBREAKDOWN OFINHIBI-

tors.

5SEONLYANTIFREEZERECOMMENDEDBY

Williamson-Thermoflo.

7ILLIAMSON4HERMOmOPROVIDESINFOR-

MATIONFORAPPLICATIONOFTHEANTIFREEZE

products listed in this document only

FORUSE IN BOILERS$O NOT APPLY THESE

PRODUCTSORINSTRUCTIONSFOROTHERAP-

plications. Local codes may require a

backflow preventer or actual disconnec-

TIONFROMCITYWATERSUPPLY

Part number 550-142-850/0716

68

FreeStyle

®

WALL MOUNT GAS-FIRED WATER BOILER — Boiler Manual

27 Startup (continued)

8. !FTERTHESYSTEMHASOPERATEDFORAWHILEELIMINATEANYRESIDUALAIRBY

using the manual air vents located throughout the system.

9. )FPURGEVALVESARENOTINSTALLEDINSYSTEMOPENMANUALAIRVENTSIN

system one at a time, beginning with lowest floor. Close vent when

water squirts out. Repeat with remaining vents.

10. Open automatic air vent (diaphragm-type or bladder-type expansion

tank systems only) one turn.

11. Starting on the lowest floor, open air vents one at a time until water

squirts out.

12. Repeat with remaining vents.

13. Refill to correct pressure.

Use of X100 inhibitor is REQUIRED

1. The FreeStyle® boiler is shipped with Sentinel X100 inhibitor and

3ENTINEL81UICK4EST+IT3EE2EPAIR0ARTSFigure 153, page 113

FORREORDERINGINFORMATION

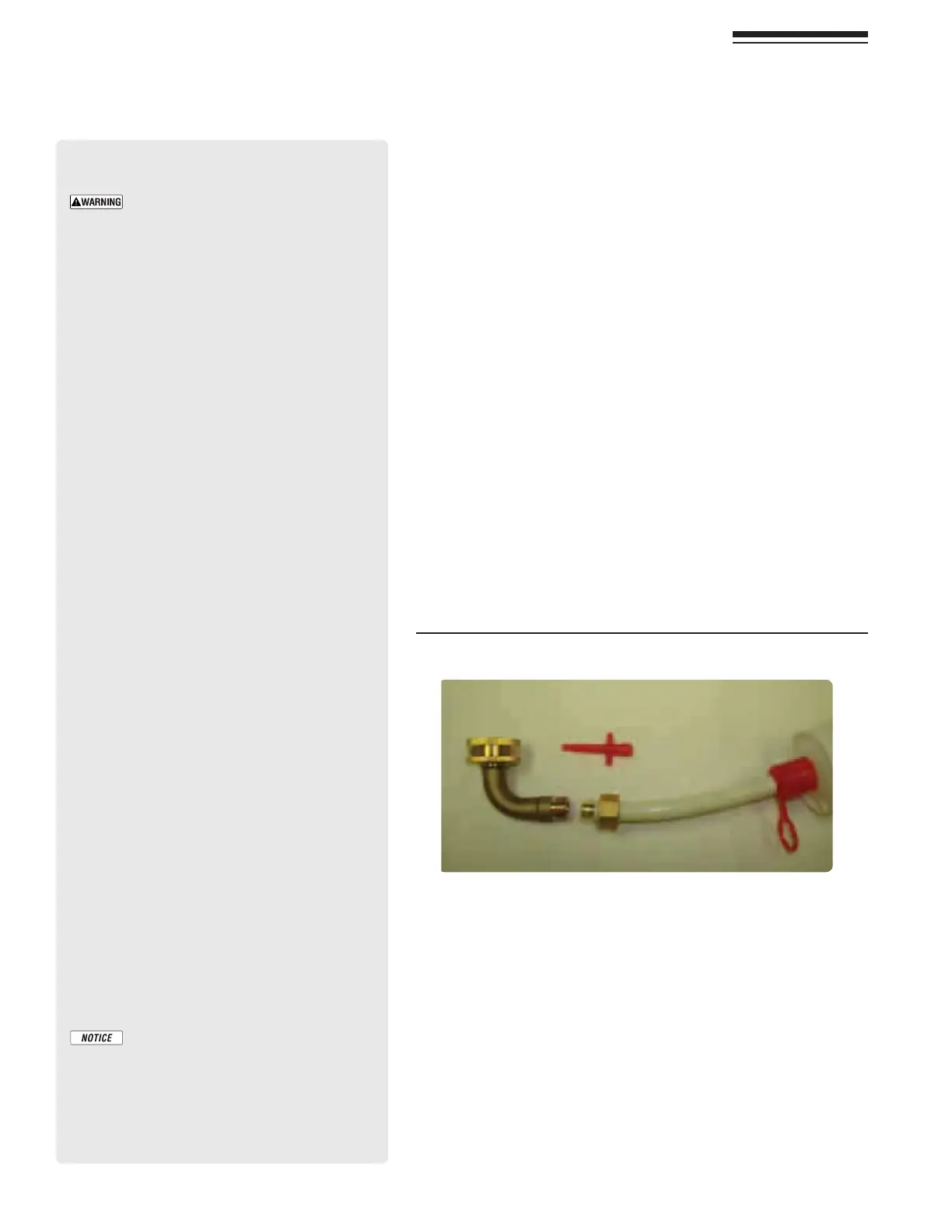

2. !FTERlLLINGTHESYSTEMASDIRECTEDINTHISMANUALANDTHEAIRPURGEHAS

been completed, release the system water pressure to 0 psi. Drain a small

AMOUNTOFWATEROUTOFACONVENIENTBOILERDRAINTOINSURETHESYSTEM

water pressure is at 0 psi. Use a (field supplied) Dishwasher elbow /

hose 3/4 to 3/8 compression adapter (See Figure 93 below) to the white

3ENTINELHOSEANDSCREWITTOTHETUBEOF3ENTINEL8)NSERTITINTO

your caulk gun, and fit the washing machine hose adapter to a boiler

DRAINCONNECTION/PENTHEDRAINANDINJECTTHECOMPLETETUBEOF8

to the system. Close the drain valve, and remove the injection fitting.

3. Fill system water to required pressure, and start a heating zone to

CIRCULATESYSTEMWATER!LLOWTIMEFORTHEWATERTOCIRCULATEANDMIX

4HENCHECKTHEINHIBITORLEVELWITHSUPPLIEDTESTKIT!DDADDITIONAL

INHIBITORIFNECESSARY

Check/verify water chemistry

1. 4HESYSTEMMAYHAVERESIDUALSUBSTANCES THAT COULDAFFECT WATER

chemistry.

2. !FTERTHESYSTEMHASBEENlLLEDANDLEAKTESTEDVERIFYWATERP(AND

chloride concentrations are acceptable.

3. 6ERIFYANTIFREEZECONCENTRATIONIFUSED

4. Follow the instructions on the Sentinel test kit to sample the system

WATERANDVERIFYINHIBITORCONCENTRATION

Figure 93 (ARDWARElTTINGSTOADD3ENTINELTOBOILER

Loading...

Loading...