Part number 550-142-850/0716

78

FreeStyle

®

WALL MOUNT GAS-FIRED WATER BOILER — Boiler Manual

31 Annual startup(continued)

The boiler should be inspected and started

ANNUALLYAT THE BEGINNING OFTHE HEATING

season, only by a qualified service technician.

)NADDITIONTHE MAINTENANCEAND CARE OF

the boiler designated in Figure 102, page 76

ANDEXPLAINEDONTHEFOLLOWINGPAGESMUST

BEPERFORMEDTOASSUREMAXIMUMBOILEREF-

ficiency and reliability. Failure to service and

maintain the boiler and system could result

INEQUIPMENTFAILURE

%LECTRICALSHOCK HAZARD 4URN OFF POWER

TOTHEBOILERBEFOREANYSERVICEOPERATIONON

the boiler except as noted otherwise in this

INSTRUCTIONMANUAL&AILURETOTURNOFFELEC-

trical power could result in electrical shock,

causing severe personal injury or death.

Address reported problems

1. )NSPECTANYPROBLEMSREPORTEDBYOWNERANDCORRECTBEFORE

proceeding.

Inspect boiler area

1. 6ERIFYTHATBOILERAREAISFREE OFANYCOMBUSTIBLEMATERIALS

gasoline and other flammable vapors and liquids.

2. 6ERIFYTHATAIRINTAKEAREAISFREEOFANYOFTHECONTAMINANTS

listed on page 8OFTHISMANUAL)FANYOFTHESEAREPRESENTIN

THEBOILERINTAKEAIRVICINITYTHEYMUSTBEREMOVED)FTHEY

cannot be removed, reinstall the air and vent lines per this

manual.

Inspect boiler exterior

1. The boiler door, panels and aesthetic parts can be cleaned

WITHASOFTDAMPCLOTHPOSSIBLYSOAKEDINSOAPYWATER$O

not use any abrasive detergents and solvents.

Inspect boiler interior

1. 2EMOVEJACKETDOORANDINSPECTINTERIOROFBOILER

2. 6ACUUM ANYSEDIMENT FROMTHEINSIDE OF THE BOILER AND

components. Remove any obstructions.

$O NOT USE SOLVENTS TOCLEAN ANYOFTHE BOILER

components. The components could be damaged,

RESULTINGINUNRELIABLEORUNSAFEOPERATION

Check all piping for leaks

ELIMINATEALLSYSTEMORBOILERLEAKS#ONTINUALFRESH

MAKEUPWATERWILLREDUCEBOILER LIFE-INERALS

can build up in the heat exchanger, reducing heat

TRANSFEROVERHEATINGHEATEXCHANGERANDCAUSING

HEATEXCHANGERFAILURE ,EAKINGWATER MAYALSO

cause severe property damage.

1. )NSPECTALLWATERANDGASPIPINGANDVERIFYTOBELEAKFREE

2. ,OOKFORSIGNSOFLEAKINGLINESINTHESYSTEMANDINTHEBOILER

ANDCORRECTANYPROBLEMSFOUND

3. #HECKGASLINEFORLEAKSSEE page 71FORGASSAFETYINFORMATION

Check ignition wiring

1. #HECKIGNITIONCABLEELECTRICALRESISTANCE!GOODCABLEWILL

HAVERESISTANCEBETWEENANDOHMS2EPLACEIFNOT

acceptable.

2. )NSPECTBOILERGROUNDWIREFROMHEATEXCHANGERACCESSCOVER

to ground terminal screw.

3. 6ERIFYALLWIRINGISINGOODCONDITIONANDSECURELYATTACHED

4. #HECKGROUNDCONTINUITYOFWIRINGUSINGCONTINUITYMETER

5. 2EPLACEGROUNDWIRESIFRESULTSARENOTSATISFACTORY

Check all boiler wiring

1. Inspect all boiler wiring, making sure wires are in good condi-

tion and securely attached.

2. 6ERIFYTHATALLCONNECTORSARESECURELYINSERTED

Check control settings

1. Use the FreeStyle® control display to navigate through all

SETTINGS!DJUSTSETTINGSIFNECESSARY

2. #HECKSETTINGSOFEXTERNALLIMITCONTROLSIFANYANDADJUST

IFNECESSARY!DJUSTASNEEDEDTOACCOMMODATETHESYSTEM

design.

Perform startup and checks

1. 3TART BOILERANDPERFORMCHECKSANDTESTSSPECIlEDINTHIS

manual.

2. 6ERIFYCOLDlLLPRESSUREISCORRECTANDTHATOPERATINGPRESSURE

DOESNOTGOTOOHIGH!DJUSTWATERPRESSUREANDEXPANSION

tank charge pressure as necessary.

3. Complete the check-out procedure on page 75.

Check burner flame

The boiler contains ceramic fiber materials. Use

care when handling these materials per instructions

on page 77OFTHISMANUAL&AILURETOCOMPLYCOULD

result in severe personal injury.

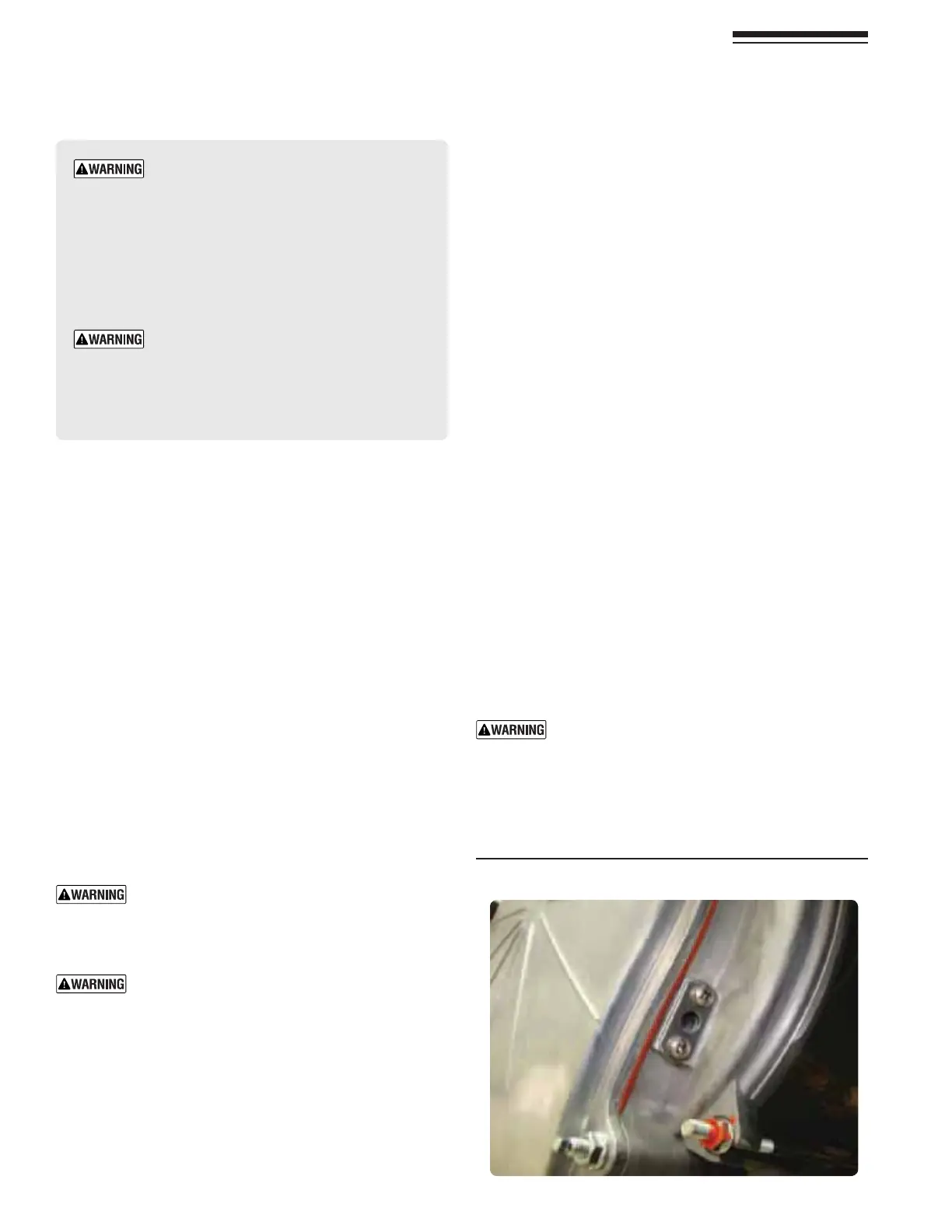

1. Inspect flame through observation window.

2. )FmAMEISUNSATISFACTORYATEITHERHIGHlREORLOWlRECHECK

COMBUSTIONVALUES)FCOMBUSTIONISPROPERLYADJUSTEDTURN

Figure 103 /BSERVATIONWINDOW

Loading...

Loading...