WARNING

A visual inspection is required by law.

Some improper couplings can pass a pull test.

Sound is not reliable.

Get out of the cab and look.

Incorrect coupling could cause the trailer to

disconnect, possibly resulting in serious

personal injury or death.

10.

Perform a coupling inspection.

10.1

Verify there is no gap between the bottom

of the trailer and the fifth wheel as shown

in

Fig. 17.7.

10.2

Make sure the jaw and wedge of the fifth

wheel are locked in place behind the

kingpin as shown in

Fig. 17.7.

10.3

Check that the lock control handle is fully

retracted as shown in

Fig. 17.3; the gap

between the back of the pull handle and

the skirt of the fifth wheel should be less

than one inch as shown in

Fig. 17.8.

WARNING

Incorrect fifth wheel locking could cause the

trailer to disconnect, possibly resulting in serious

personal injury or death.

11.

Release the tractor parking brakes.

Test for kingpin lockup by slowly inching the

tractor forward, pulling on the trailer against the

chocks.

12.

After lockup is completed and verified, connect

the tractor-to-trailer air system lines and the

electrical cable to the trailer. Take care to prevent

f31134708/24/2021

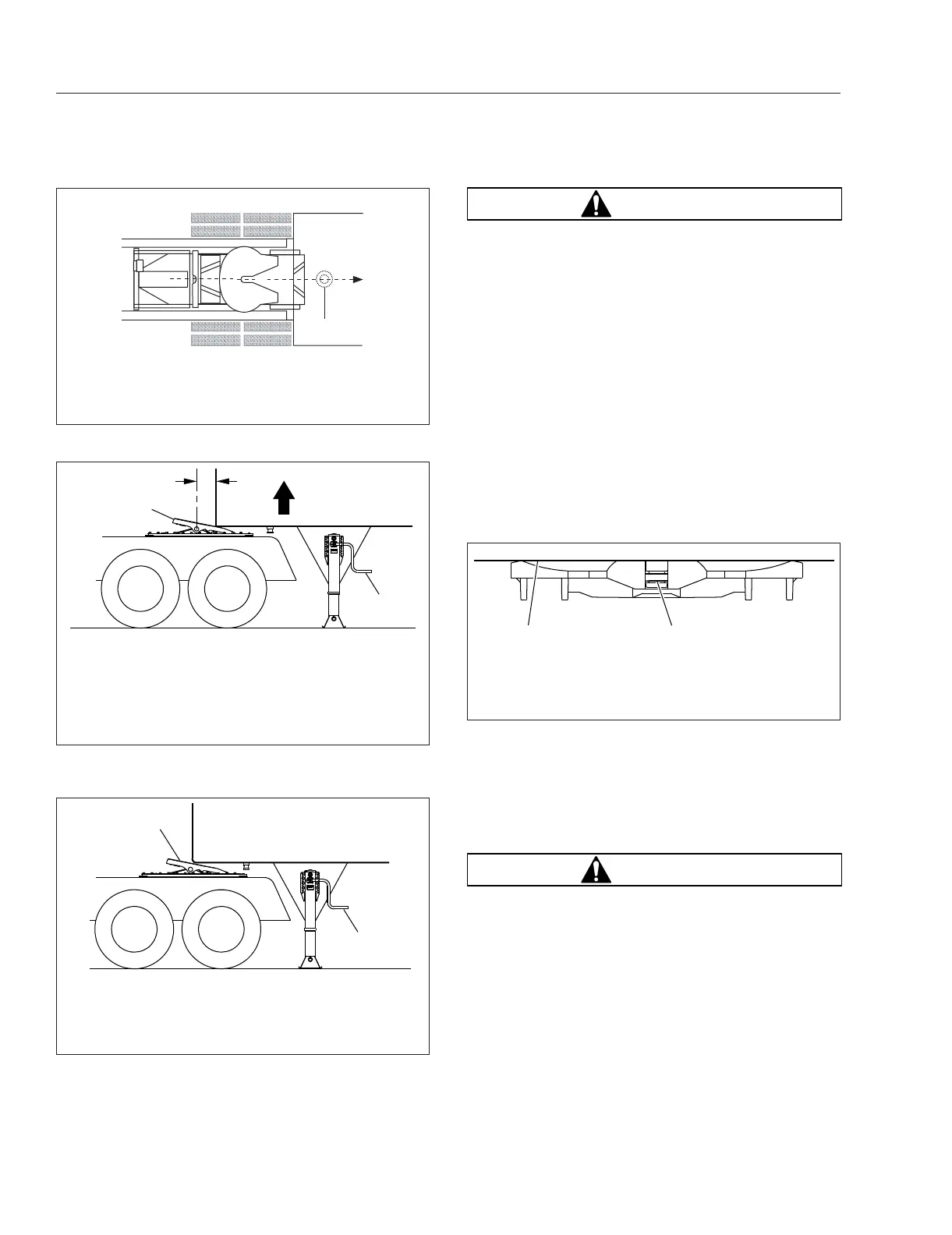

A

1

A. Line up the fifth wheel throat with the trailer kingpin.

1. Kingpin

Fig. 17.4, Positioning the Tractor

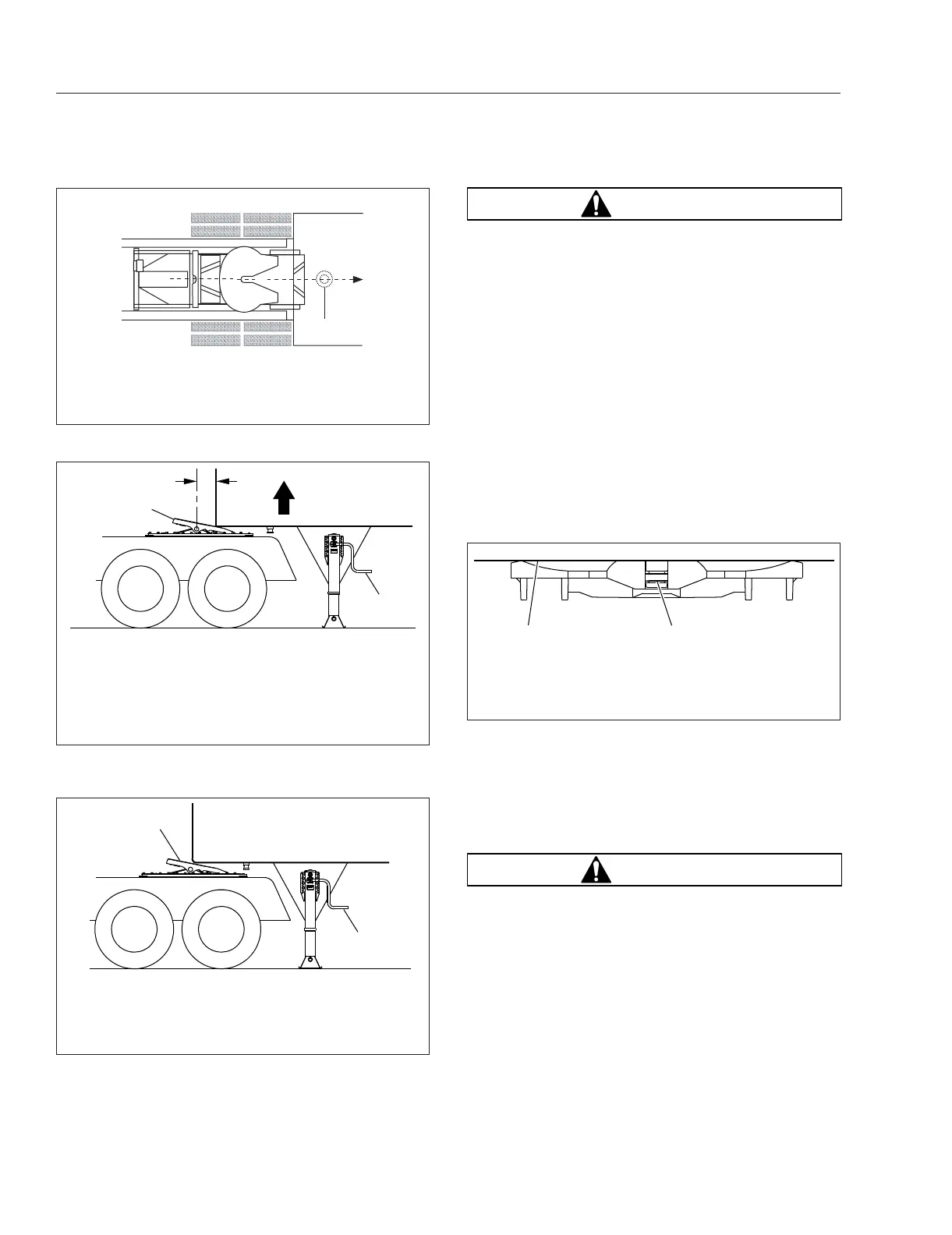

f31112404/28/2017

A

B

C

D

A. The fifth wheel must lift the trailer.

B. Adjust the trailer height if necessary.

C. Tilt the ramps down.

D. Trailer should contact fifth wheel 4-6 inches behind

pivot point.

Fig. 17.5, Trailer Connection Point, Standard Fifth

Wheel

f31112504/28/2017

A

B

A. Adjust trailer height as needed.

B. Verify pivot point allows fifth wheel to slide under

trailer.

Fig. 17.6, Trailer Connection Point for No- and Low-

Lube Fifth Wheels

f31112604/28/2017

AB

A. Check that there is no gap between the trailer and

fifth wheel.

B. Verify the kingpin is locked in the fifth wheel jaws.

Fig. 17.7, Coupling Inspection View

Fifth Wheels and Trailer Couplings

17.3

Loading...

Loading...