55 PB

EXTERNAL STATIC PRESSURE

External Static Pressure can best be defined as the pressure difference (drop) between the Positive Pressure (discharge) and the

Negative Pressure (intake) sides of the blower. External Static Pressure is developed by the blower as a result of resistance to airfl

ow (Friction) in the air distribution system EXTERNAL to the VRP cabinet.

Resistance applied externally to the VRP (i.e. duct work, fi lters, etc.) on either the supply or return side of the system causes an

INCREASE in External Static Pres‑sure accompanied by a REDUCTION in airfl ow.

External Static Pressure is affected by two (2) factors;

1. Resistance to Airflow as already explained.

2. Blower Speed. Changing to a higher or lower blower speed will raise or lower the External Static Pressure accordingly.

These affects must be understood and taken into consideration when checking External Static Pressure/Airfl ow to insure that the

system is operating within design conditions.

Operating a system with insufficient or excessive airflow can cause a variety of different operating problems. Among these are

reduced capacity, freezing evaporator coils, premature compressor and/or heating component failures. etc.

System airflow should always be verified upon completion of a new installation, or before a change‑out, compressor replacement, or

in the case of heat strip failure to insure that the failure was not caused by improper airflow.

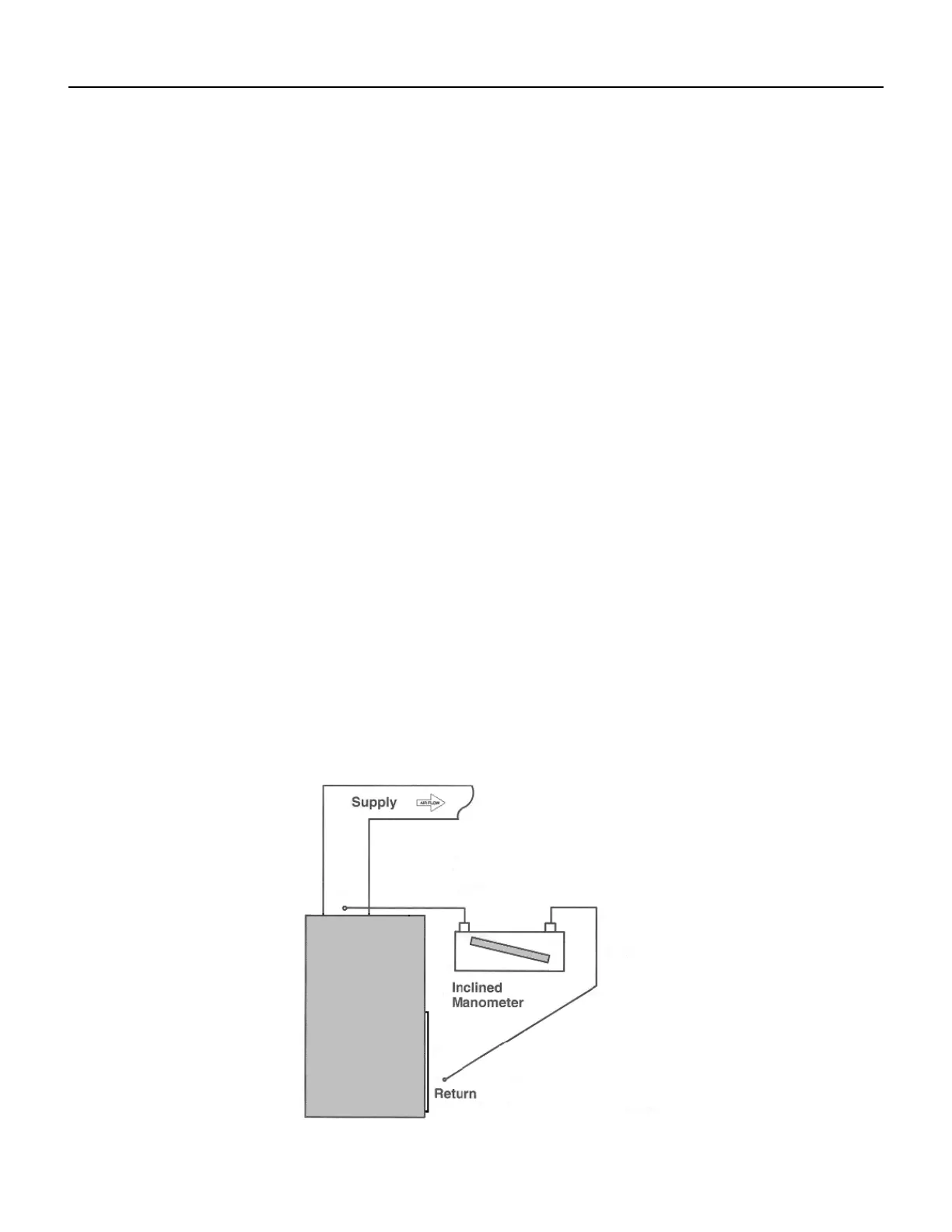

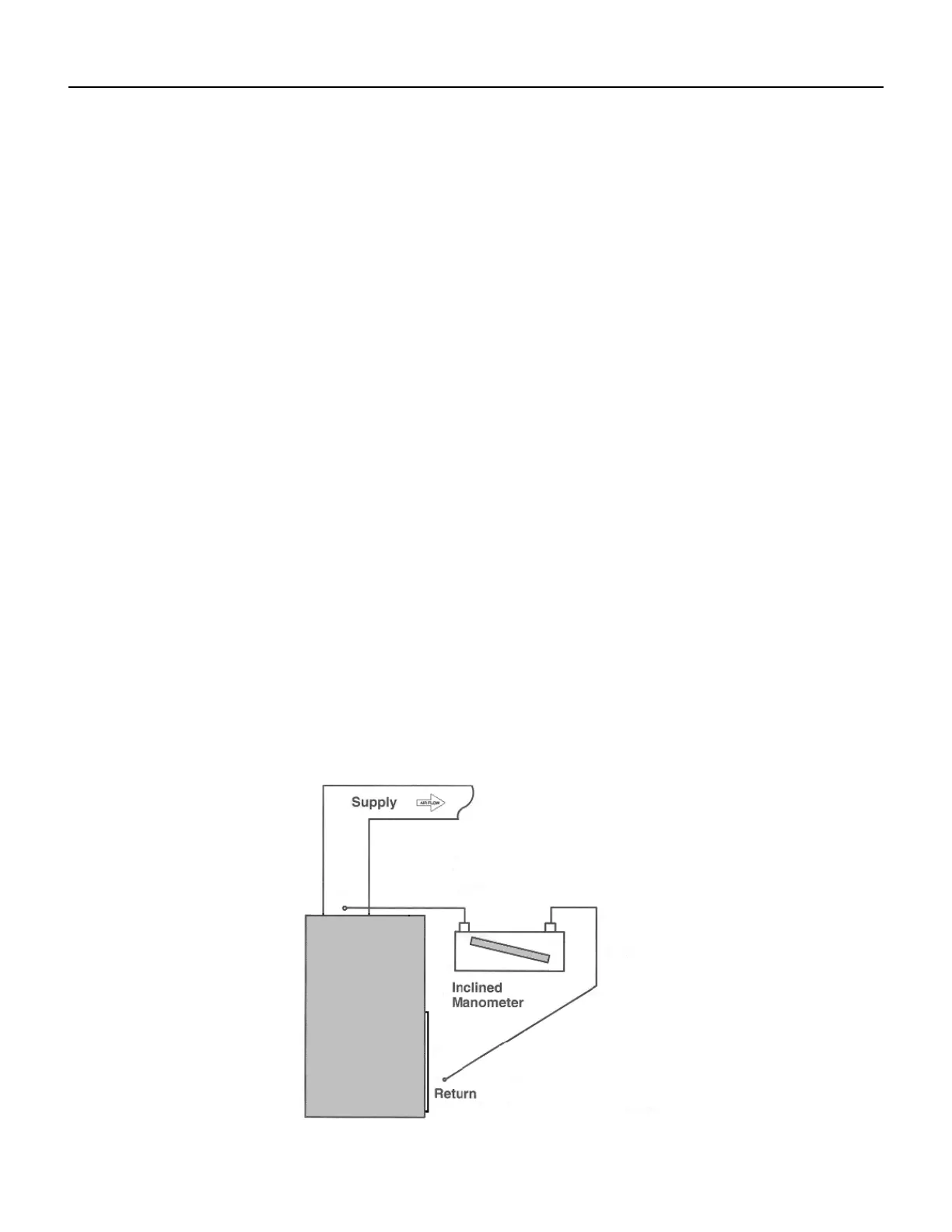

Checking External Static Pressure

The airow through the unit can be determined by measuring the external static pressure of the system, and consulting the

blower performance data for the specic VRP.

1. Set up to measure external static pressure at the supply and return air.

2. Ensure the coil and lter are clean, and that all the registers are open.

3. Determine the external static pressure with the blower operating.

4. Refer to the Air Flow Data for your VRP system to nd the actual airow for factory-selected fan speeds.

5. If the actual air ow is either too high or too low, the blower speed will need to be changed to appropriate setting

or the ductwork will need to be reassessed and corrections made as required.

6. Select a speed, which most closely provides the required airow for the system.

7. Recheck the external static pressure with the new speed. External static pressure (and actual airow) will have

changed to a higher or lower value depending upon speed selected. Recheck the actual airow (at this “new” static

pressure) to conrm speed selection.

8. Repeat steps 8 and 9 (if necessary) until proper air ow has been obtained.

EXAMPLE: Airow requirements are calculated as follows: (Having a wet coil creates additional resistance to airow. This

additional resistance must be taken into consideration to obtain accurate air ow information.

Loading...

Loading...