EN

FRIGOMAT KREAM 2.5 E M04.37389 R.2022.03.30 6

1 PREPARATION FOR USE

Wash and sanitize the machine as indicated in IV-1 / I-V-2 of this manual.

2 PRELIMINARY CHECKS

The following checks must be made every time you want to start

production.

2.1 Machine checks

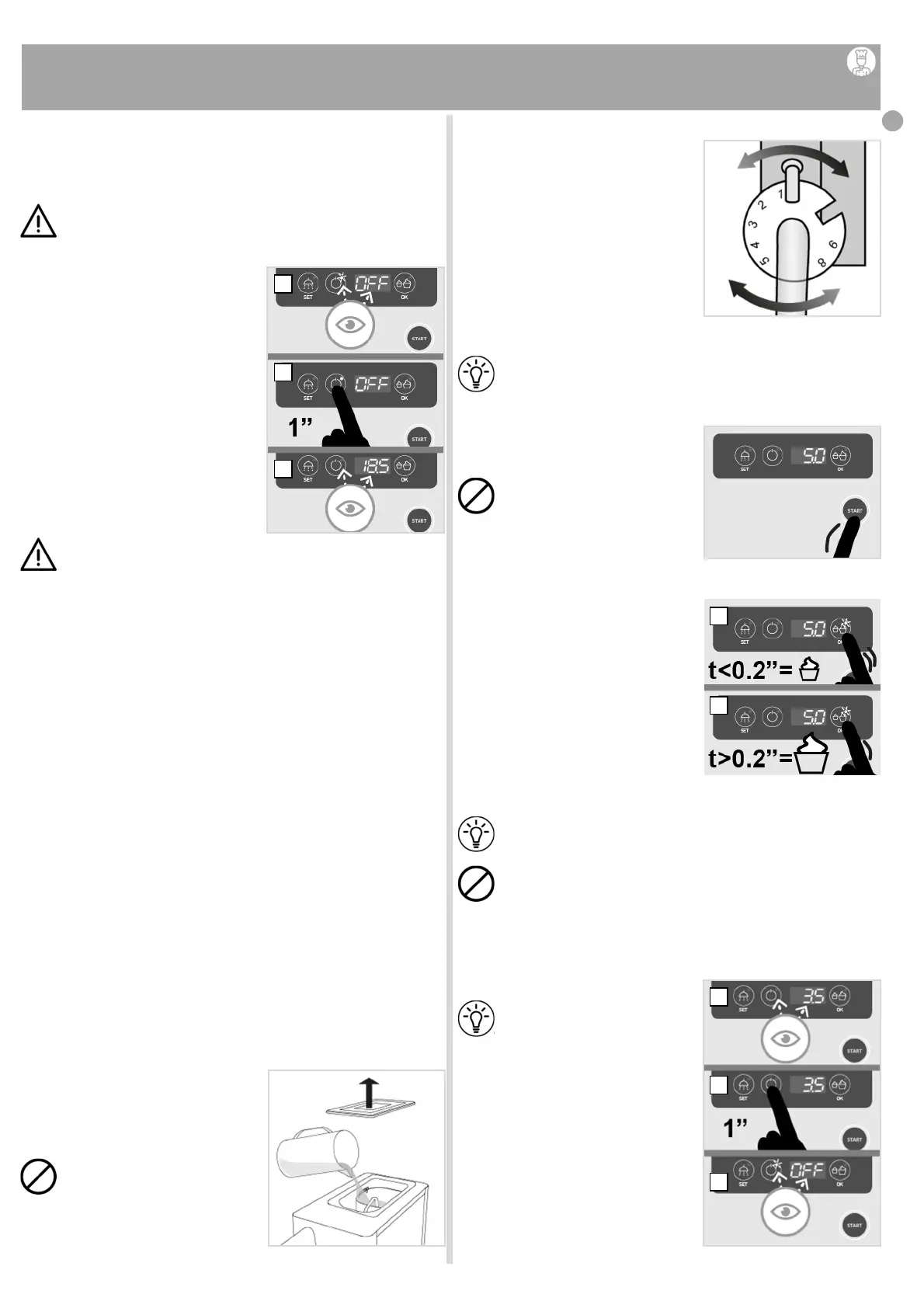

Make sure the master switch is closed and

that the machine is powered correctly

(fig.III/01-A).

Switch on the machine by pressing the ON-

OFF button for approx. 1 sec. (fig.III/01-B),

check that the 2 leds of the ON-OFF button

are active and that the display shows the

storage temperature (fig.III/01-C).

Check that all the machine parts are present

and correctly assembled.

Verify that the machine is empty, clean and

correctly sanitized.

Check that there are no alarms shown on

the display and that the temperature

displayed is correct.

To avoid bacterial contamination and to obtain

maximum performance from the machine, activate the

machine clean and empty and wait 10 min. and/or the

temperature of about 4°C on the display before pouring the pro-

duct in the tank and start the production.

Note: during the cooling phase, any indication of negative

temperatures on the display does not constitute a malfunction of the

machine.

2.2 Check cream and/or cream + sugar mix

To avoid the risk of malfunction or damage to the machine, the following

checks must also be carried out on the product to be used:

- Use only quality cream with a fat content between 30 and 38%.

- Do not use specific cream for equipment other than the cream whipper

(e.g.: orbital, etc.).

- Check that the cream + sugar mix is of quality and balanced (sugar ≤10%).

- Check that the mix is fluid, homogeneous, without lumps and not separated.

- It is recommended to use powdered sugar or liquid sugar. If granular sugar

is used, make sure it is completely dissolved before delivery.

- Mix the product periodically (at least once every 2 hours) in the tank to

avoid the separation of the heavier solid parts.

- Never add solid substances to the cream, such as hazelnut pieces,

chocolate pieces, etc., which would obstruct the pump and damage the

machine.

To avoid bacterial contamination and to obtain maximum performance from

the machine, always keep the mixture stored at a temperature below 5 °C

(41 °F).

3 WHIPPED CREAM DELIVERY

3.1 Loading product

Lift the cover (fig.III/02).

Pour the cream into the extractable tray,

respecting the minimum and maximum

quantities allowed:

Min: 0,5 kg Max: 2.5 kg

Take care not to pour the cream outside the

removable tank (fig.III/02).

Always pour the cream into the

removable tank and not into the

general compartment to ensure

perfect hygiene of the product and

easier cleaning of the machine.

Replace the cover to avoid contamination of

the product.

3.2 Cream whipper regulation

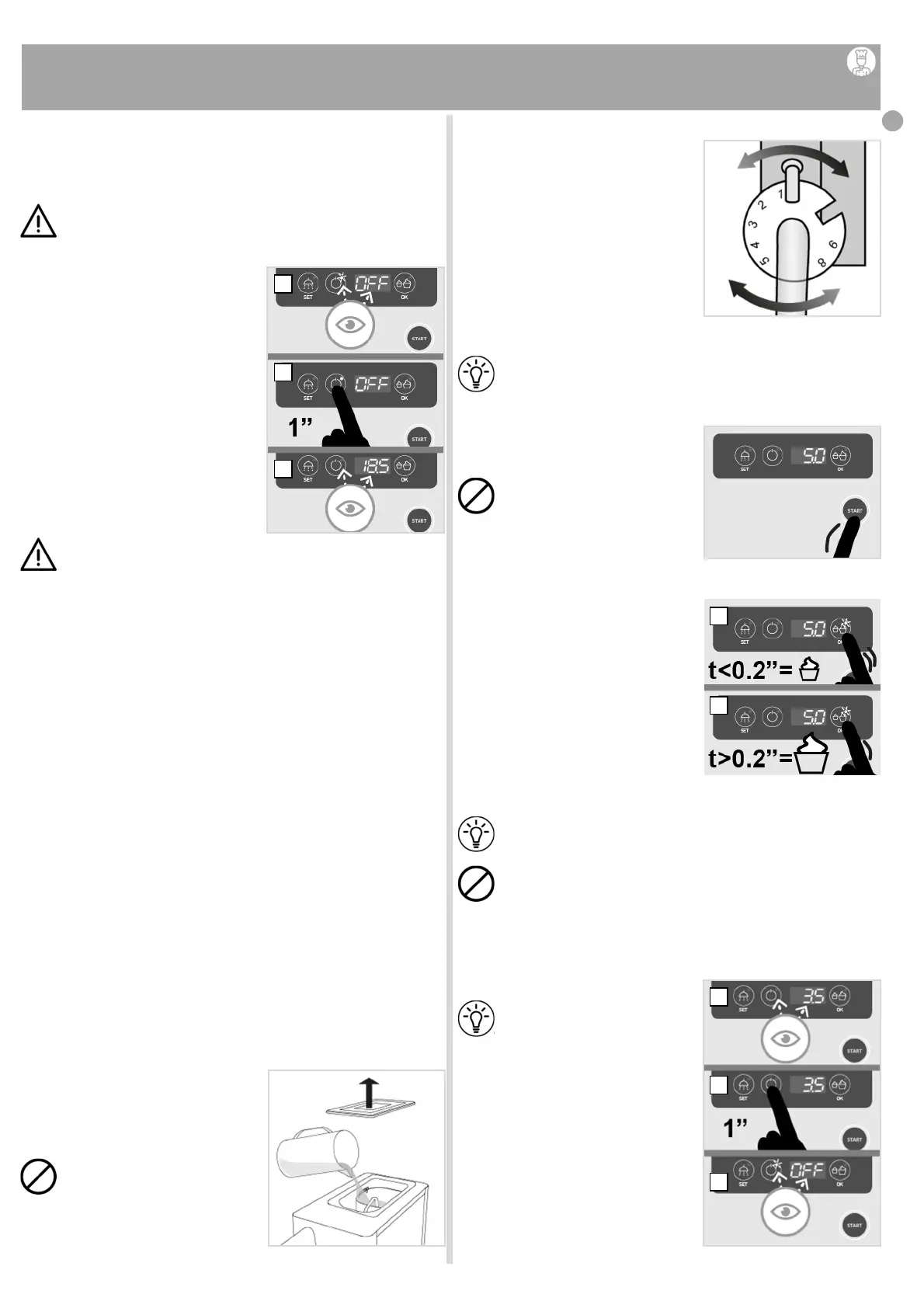

By acting on the cream regulator (fig. III/03)

it is possible to obtain the correct air-liquid

mix and therefore an excellent whipped

cream.

To make a correct adjustment, it is always

preferable to start from a middle position

(e.g. 3-5) and turn the regulator

progressively to the other positions until the

desired product is obtained.

Turning the regulator to low positions will

result in a more liquid product.

Turning the regulator to high positions

increases the air flow and produces a more

whipped product.

Different creams require different position for whipping.

Not all products can be whipped at any setting value.

3.3 Delivery

To dispense whipped cream, press and hold

the START button to extract the desired

amount (fig.III/04).

Do not deliver with extractable

tank empty or with insufficient

product level to ensure the correct

draught of the pump.

3.4 Timed Delivery

Small dose

Press and release (t<0.2") the DOSE button,

the dispensing will be activated for the set

time, if > 0.0 sec. (see chap. III 3.5 for

display and modification of timed small dose

dispensing time). The led next to the ON-

OFF key will be activated for the duration of

dispensing (fig.III/05 "A").

Large dose

Press and keep pressed (t>0,2") the DOSE

button, the dispensing will be activated for

the set time, if > 0.0 sec. (see chap. III 3.5

for visualization and modification of timed

dispensing time of large dose). The led next

to the ON-OFF key will be activated for the duration of dispensing

(fig.III/05 "B").

Use this function if you need to make frequent cream dispensing

at constant times.

Do not deliver with extractable tank empty or with insufficient

product level to ensure the correct draught of the pump.

3.5 Display/Adjustment Timed dispensing time

See Chapt. V/1 “USER MENU”

3.6 Display - Adjustment Storage temperature

See Chapt. V/1 “USER MENU”

Use this function if you need to

change the storage temperature of

the product in the removable tray.

3.7 Switching off the machine

Switch the machine off by pressing the ON-

OFF button for about 1 sec. (fig.III/06-B),

check that both the LEDs on the ON-OFF

button are on and that the display shows the

storage temperature (fig.III/06-C).

III USE

for the operator

fig.III/04

fig.III/01

C

B

A

fig.III/06

C

B

A

fig.III/03

fig.III/02

fig.III/05

B

A

Loading...

Loading...