EN

FRIGOMAT KREAM 2.5 E M04.37389 R.2022.03.30 7

4 OPERATIONAL ROUTINES

This procedure must be performed once daily.

4.1 Daily Closing

This procedure must be performed

once daily, before the night

closing.

Wash your hands well and/or wear

disposable gloves.

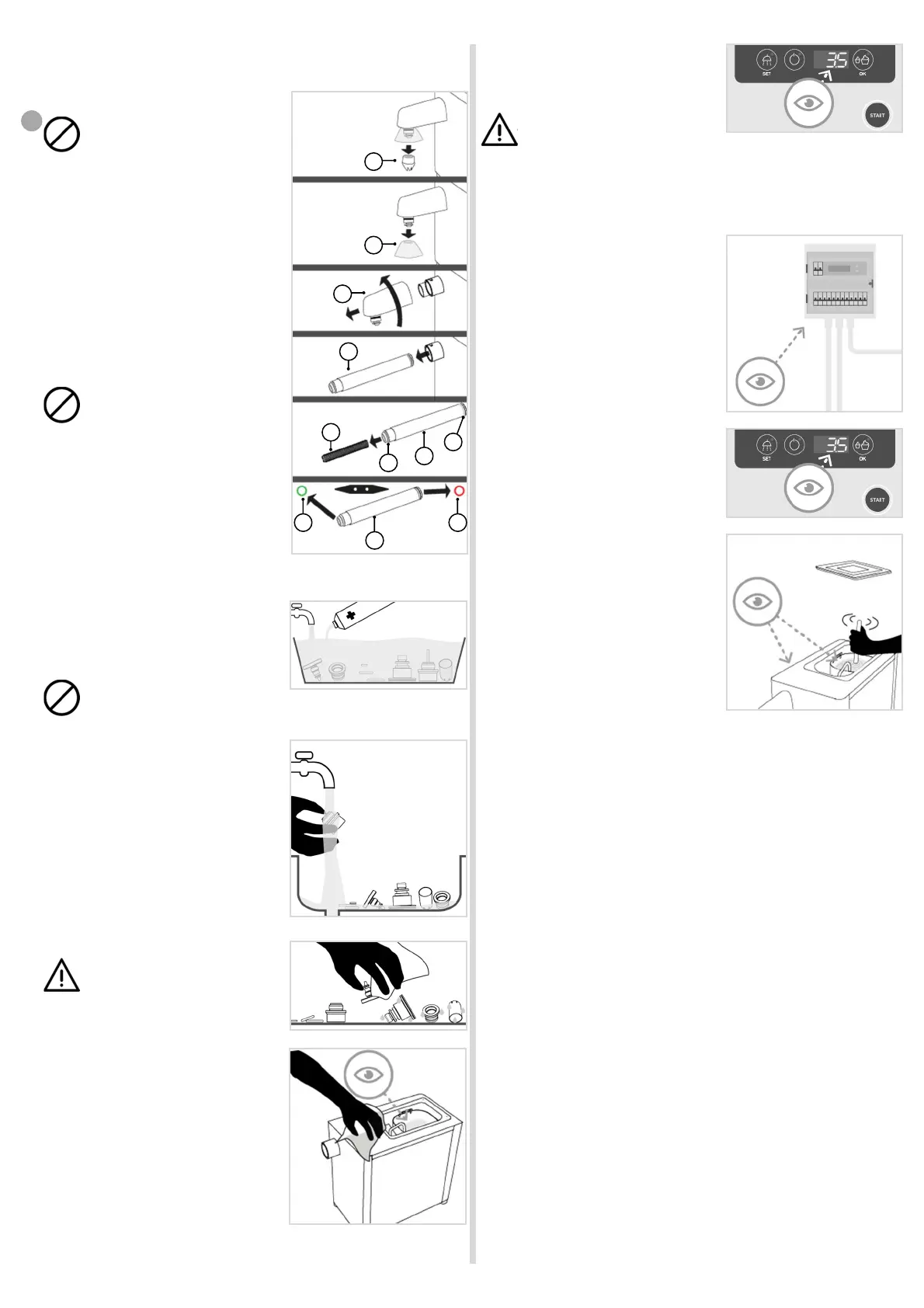

Pull down the star nozzle (fig. III/07 "a")

Pull down the splash guard (fig. III/07 "b")

Turn the nozzle body counterclockwise (fig.

III/07 "c") and pull it towards you to remove it

from its seat.

Remove the labyrinth cover (fig. III/07 "d").

Remove the labyrinth (fig.III/06 "e”) from the

labirynth cover (fig.III/07 "d”).

Remove the gaskets (fig. III/07 “h, g”) using

the O-Ring disassembling tool.

Pay attention to the positioning of

the RED and GREEN gaskets on

the labyrinth cover in order to

correctly reassemble the labyrinth

cover.

Emerge the previously disassembled com-

ponents into the tub with the sanitizer and

brush the surfaces with care. Pay special

attention to the internal ducts and to the

labyrinth notches (fig. III/08).

All the parts previously

disassembled must remain immersed in the sanitizing

solution for the time provided by the sanitizer manufacturer

Rinse the components with plenty of cold

drinking water, taking care to remove all

possible residues of sanitizing solution (fig.

III/09).

Dry with disposable paper (fig. III/10).

Do not use rags, sponges or

anything else to dry the

components. Make sure no dust or

other impurities come into contact with

the sanitized surfaces while they are

drying.

Thoroughly clean the external and internal

surfaces of the machine with disposable

paper previously soaked with detergent/

sanitizing liquid, taking care to avoid any

contact of the sanitizer with the food product

contained inside the removable tank (fig.

III/11).

Wait a few minutes and rinse carefully to

remove any traces of the sanitizer

previously applied.

Dry with disposable paper.

Reassemble the previously disassembled

components.

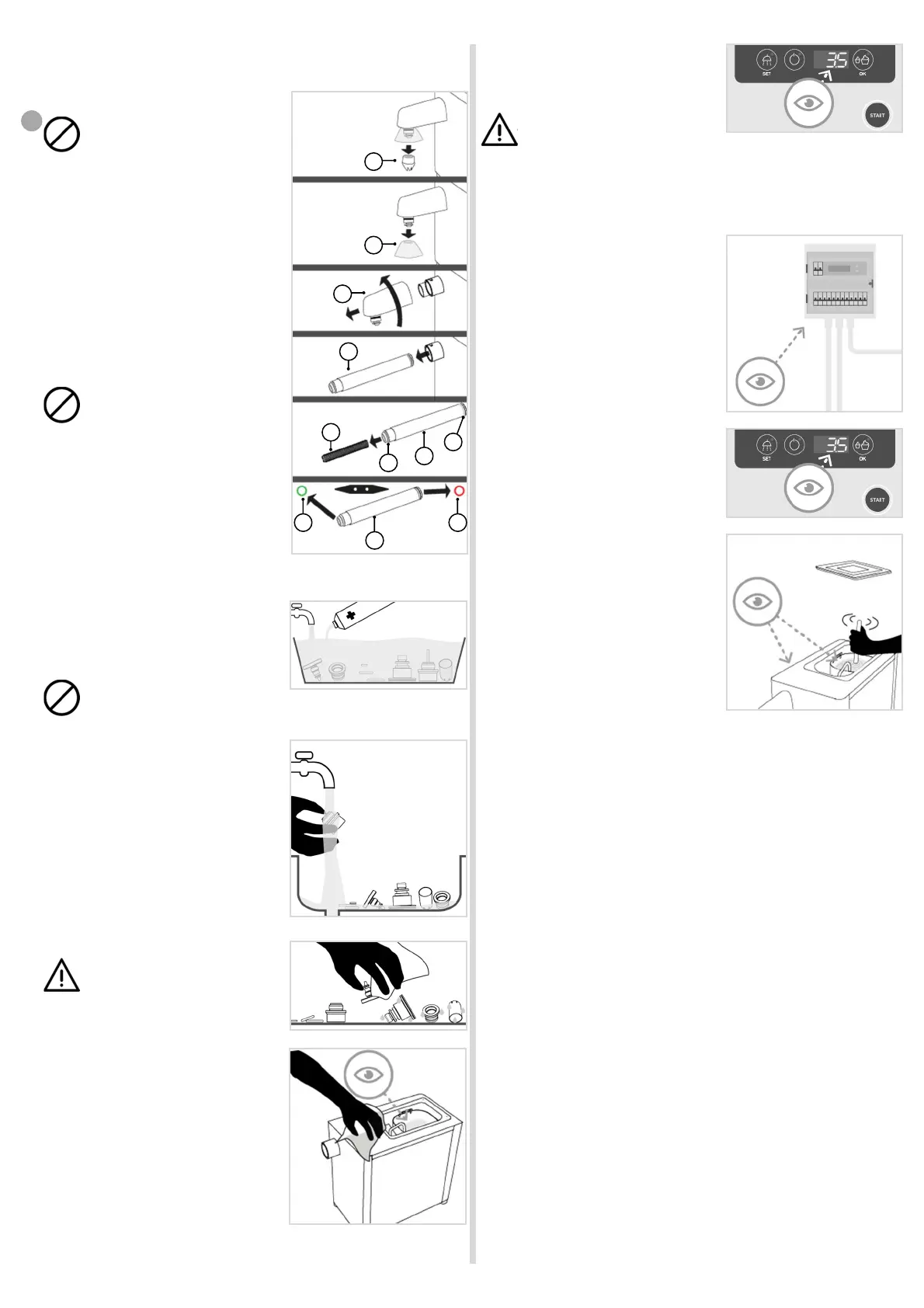

Check that the machine is in

“ON" (fig.III/12).

Never switch off the machine with

the product inside, as raising the

temperature would cause a risk of bacterial proliferation.

4.2 Daily Opening

The following procedure must be performed at the beginning of each

work session, at the end of a long administration break

Make sure that during the pause there has

not been a power failure (blackout) (fig.

III/13): in this case the product may be

contaminated and no longer suitable for

administration. In this case, remove the

product and clean and sanitize the machine.

Check that there are no alarms shown on

the display (fig. III/14).

Mix the product in the tank and check that it

is homogeneous, without lumps and not

separated. Check that the machine has

remained clean, not contaminated by dust,

impurities or insects (fig.III/15).

fig.III/08

fig.III/14

fig.III/13

fig.III/12

fig.III/09

fig.III/10

a

b

c

d

e

d

fig.III/07

f g

RED/ROSSO

ROUGE/ROT/ROJA

f

g

d

GREEN/VERDE

VERT/GRUN

fig.III/11

fig.III/15

Loading...

Loading...