20

Application

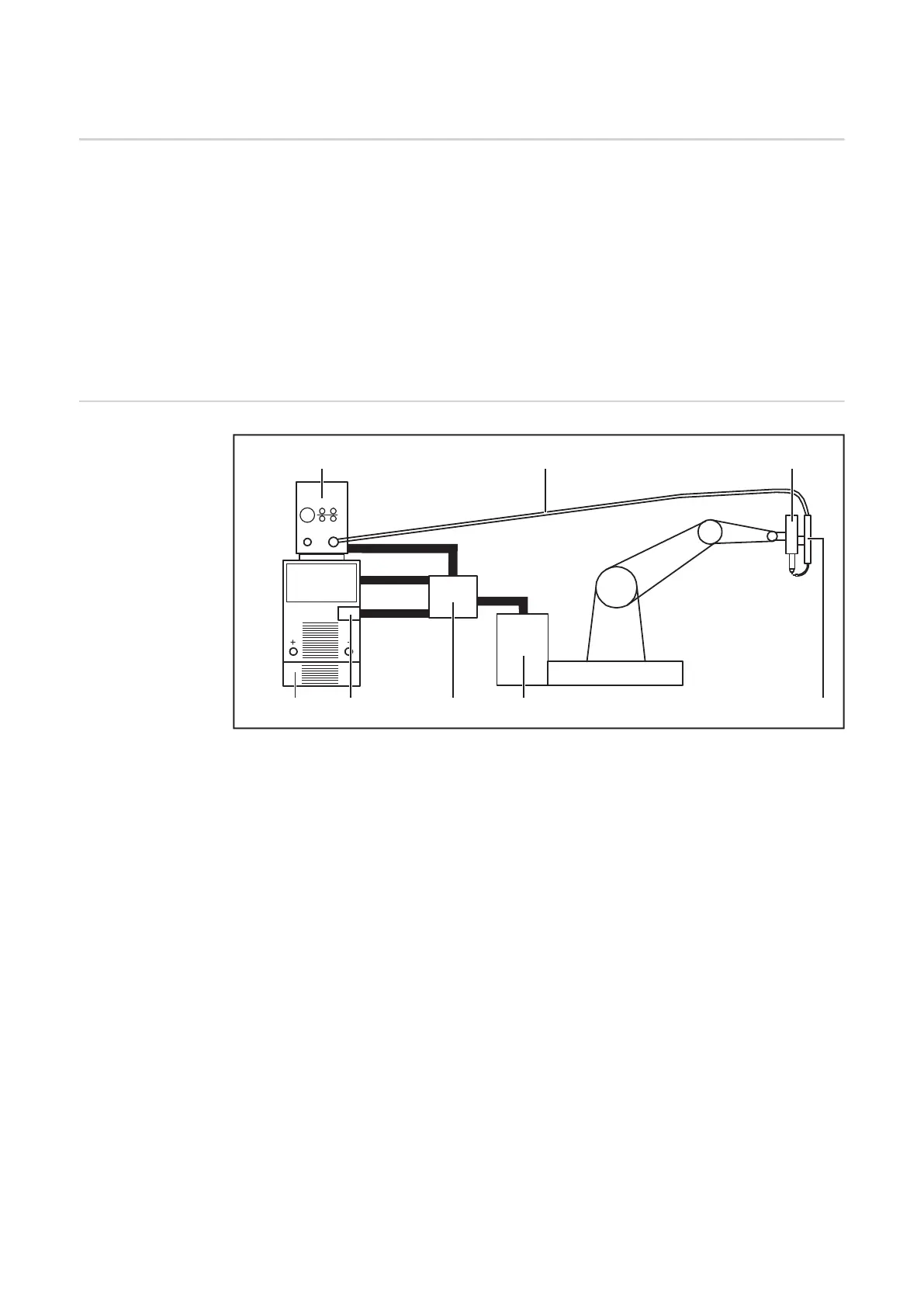

General IMPORTANT! The figures below show configuration examples for the KD 7000 with an in-

dustrial robot and a Fronius TIG power source. The configuration examples shown apply

by analogy to welding machines and cold wire TIG welding applications with laser welding

systems.

Figures 1 and 2 apply by analogy to manual TIG welding with cold-wire feed.

Recommended for welding machines

- Wirespool and 4 roller drive integrated in KD 7000

- Wire pushed by integrated 4 roller drive

- Length of the wirefeed hosepack: up to 3.5 m

Configuration 1:

unalloyed/high-

alloy steels

(Push/Internal)

Configuration 1 - Wirespool and wire drive on KD 7000, wire pushed

(1) KD 7000 with wirespool holder and 4 roller drive

(2) Wirefeed hosepack

(3) Welding torch

(4) Wirefeed

(5) Robot control

(6) TIG-KD connection box

(7) Power source robot interface

(8) Power source

Limitation in the case of aluminium:

- Length of hosepack may not exceed 1 m

(1) (2) (3)

(4)(5)(6)(7)(8)

Loading...

Loading...