2-3

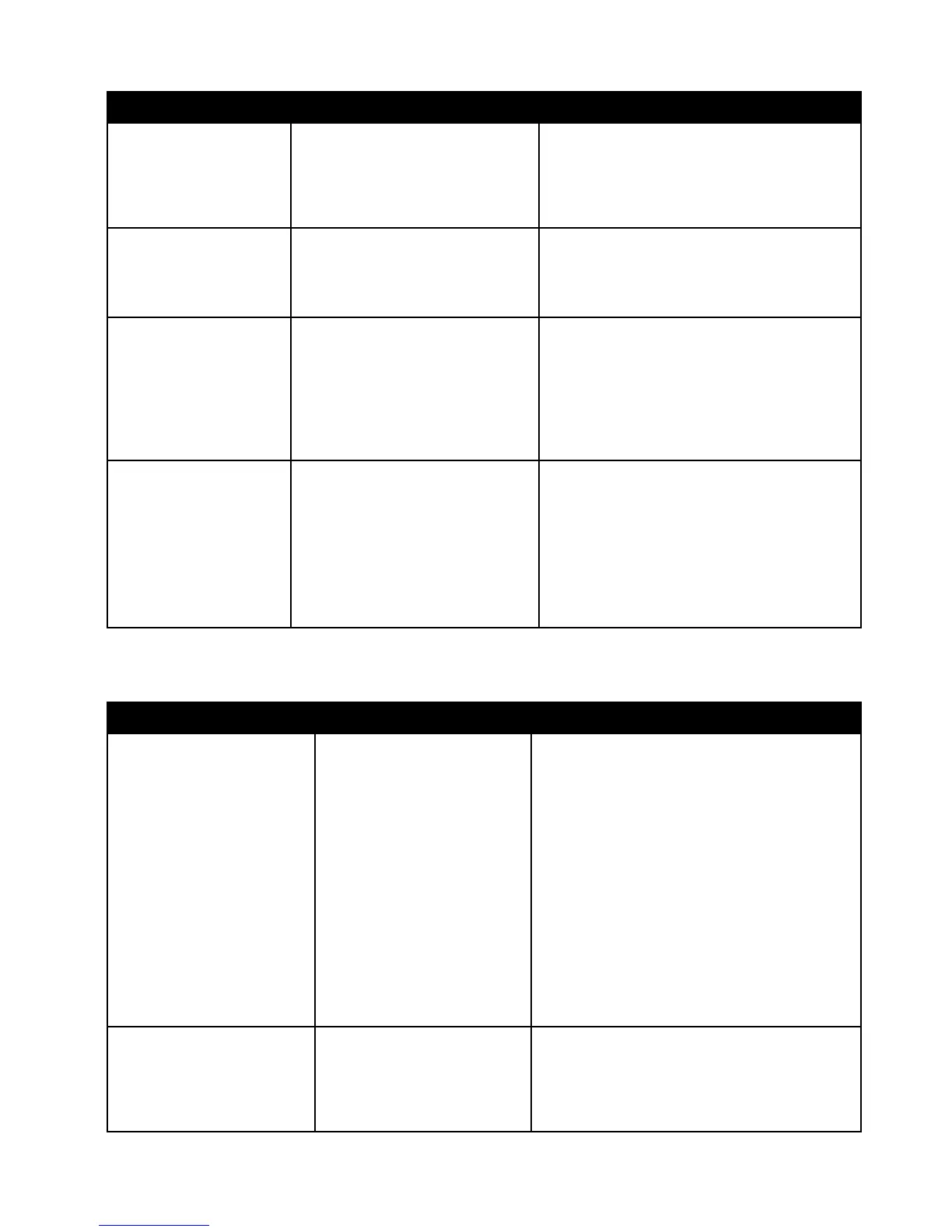

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

Controller displays

HEATING

FAILURE.

Contactor issue, gas valve off,

failed controller, failed

transformer, open high-limit

thermostat.

It is normal for this message to appear during

startup if a gas fryer’s lines have air in them.

Check that the gas valve is on. If it continues,

shut the fryer down and call your FAS for

assistance.

Controller displays

SERVICE

REQUIRED followed

by an error message.

An error has occurred which

requires a service technician.

Press

(NO) to continue cooking and call

your FAS for assistance. In some cases,

cooking may not be allowed.

Controller displays

IS VAT FULL?

YES NO during a

cook or in idle mode

with an audible

alarm.

A. An error has occurred due to

carbon buildup on oil level

sensor.

B. CAN communication issues,

component failure issues.

C. OIB relay ground issue.

A. If answering yes directs to IS OIL

SENSOR CLEAN? CONFIRM, clean the

oil level sensor with a scratch pad and

power cycle the controller.

B. If the issue persists contact your FAS for

assistance.

C. Contact your FAS for assistance.

Controller displays

IS OIL

SENSOR

CLEAM?

CONFIRM during

a cook or in idle

mode with an

audible alarm.

A. The oil level sensor may be

coated with caramelized oil.

B. CAN communication issues,

component failure issues.

C. OIB relay ground issue.

A. Clean sensor with scratch pad.

B. If the issue persists contact your FAS for

assistance.

C. Contact your FAS for assistance.

2.2.2 Filtration Problems

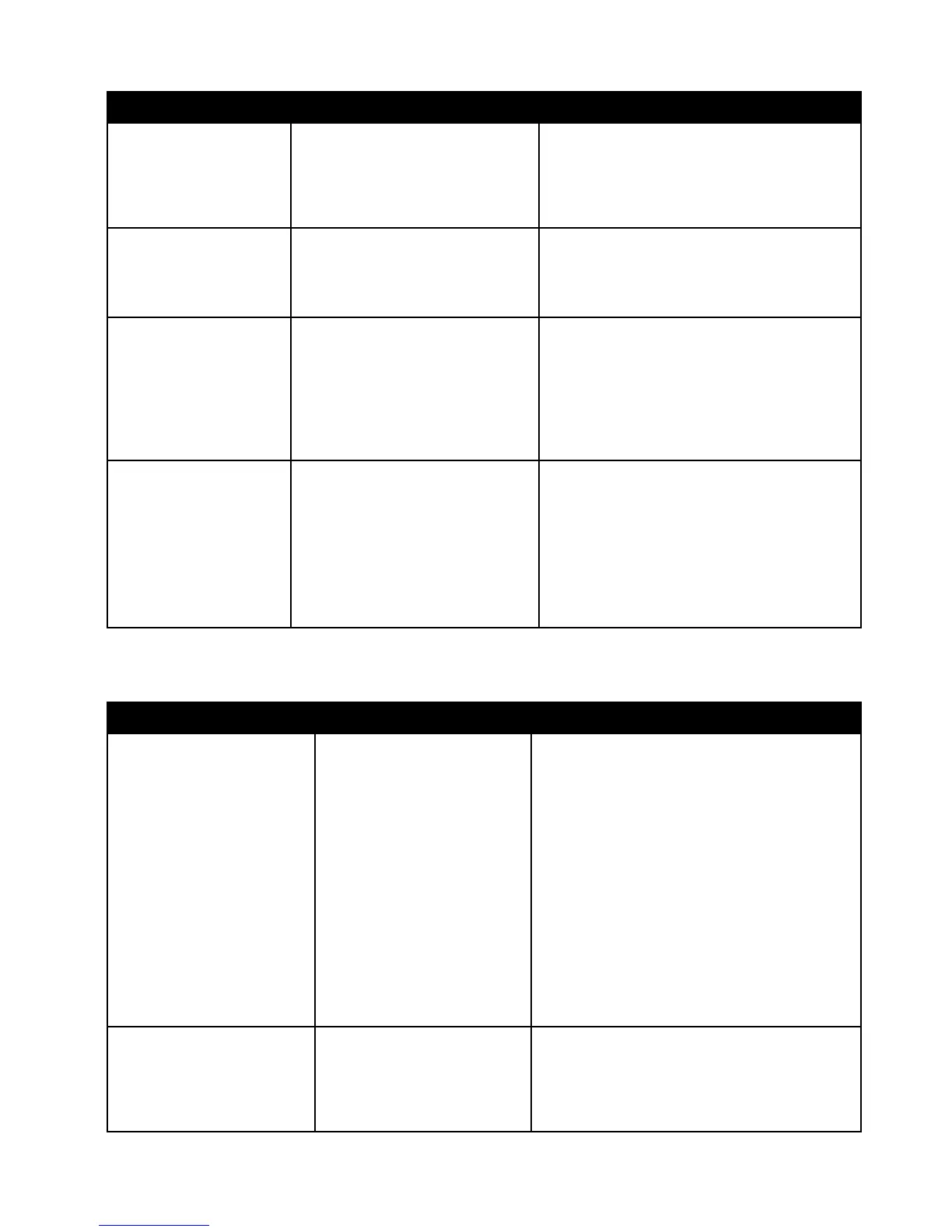

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

Controller displays IS

VAT FULL? YES

NO after a filter

function.

A. An error has occurred due

to carbon buildup on oil

level sensor. Normal after

some filter menu functions

when filling.

B. All the oil may not have

returned during a filter

function due to dirty or

clogged filter paper,

clogged filter pump, filter

pump thermal overload,

improperly installed filter

pan components, worn or

missing O-rings, cold oil or

an actuator problem.

A. If answering yes directs to clean oil sensor,

clean oil level sensor with a scratch pad and

retry. Otherwise press (YES) if the vat is

full, otherwise press (NO) and follow

prompts.

B. Check to ensure that the probable causes

are remedied. Follow the prompts to refill

the vat.

CLEAN, POLISH,

FILTER OR DISPOSE

won’t start.

A. Temperature too low or

controller displays OFF.

B. Messages or errors on

other controllers.

C. Filter pan not fully

A. Ensure fryer is at 250°F (121°C) or setpoint

before starting; ensure the controller is ON.

B. Clear messages and errors on other

controllers.

C. Ensure the filter pan is in position and fully

Loading...

Loading...