30

(4) AC/DC Drive object (Class 2A hex.)

This object monitors the current speed command settings and the current speed of the inverter, and configures

their related settings. It also monitors the output data issued from the inverter.

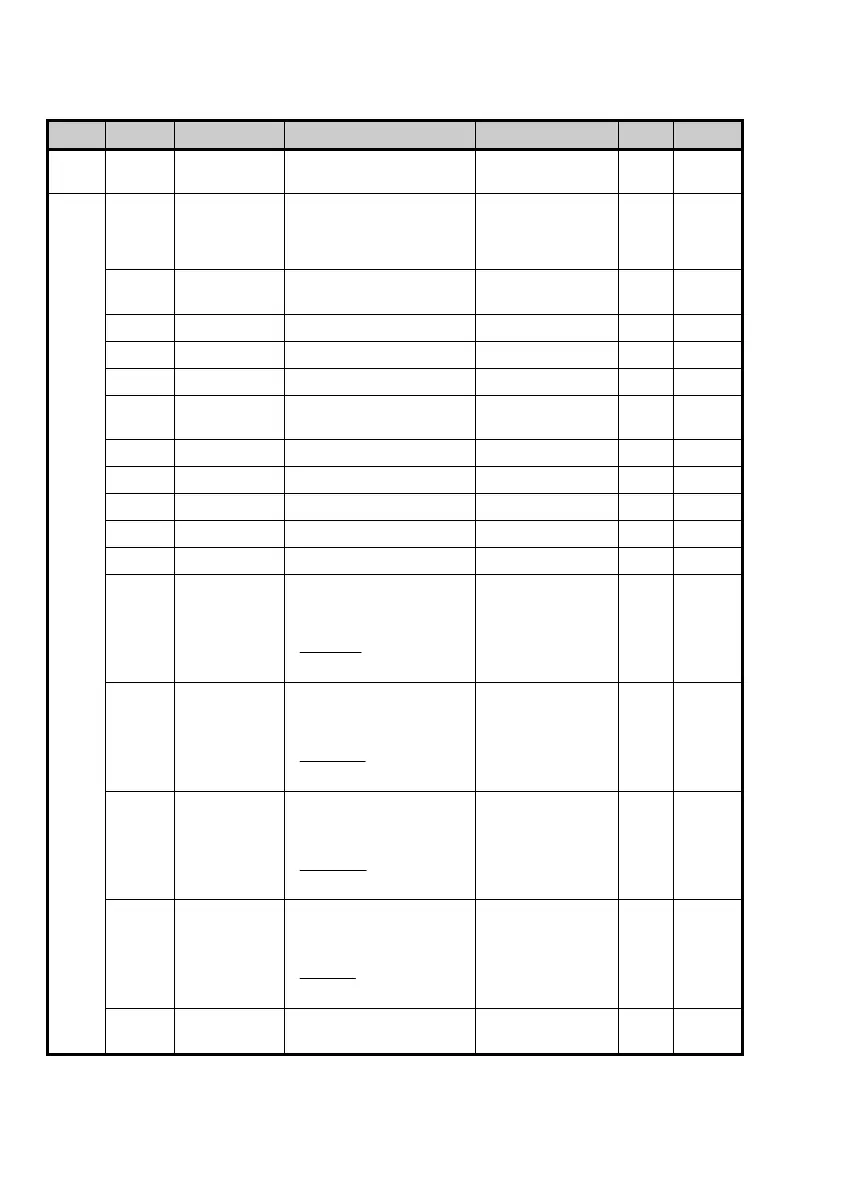

Instance Attribute Name Description Value (hex.) R/W Data size

0 01 hex Revision Revision number of AC/DC

Drive object

0001 R Word

1 03 hex AtReference Speed arrival 00: Stopped/

Accelerating or

decelerating

01: Speed arrival

R Byte

04 hex NetRef Switching speed command

source

00: Inverter

01: DeviceNet

R/W Byte

06 hex DriveMode Run mode. Fixed at 0. 00: Unique to vendor R Byte

07 hex SpeedActual Speed monitor (r/min) Actual speed R Word

08 hex SpeedRef Speed command (r/min) -32768 to 32767 r/min R/W Word

09 hex CurrentActual Output current

(in units of 0.1 A)

Output current R Word

11 hex OutputVoltage Output voltage (V) Output voltage R Word

12 hex AccelTime Acceleration time (ms) 0 to 65535 ms R/W Word

13 hex DeccelTime Deceleration time (ms) 0 to 65535 ms R/W Word

14 hex LowSpdLimit Lower limit speed (r/min) 0 to 32767 r/min R/W Word

15 hex HighSpdLimit Maximum speed (r/min) 0 to 32767 r/min R/W*

1

Word

16 hex SpeedScale Change the speed scale

(r/min) all at once, as

calculated below.

SpeedScale

2

r/min

-15 to 15

(Factory default: 0)

R/W Byte

17 hex CurrentScale Change the current scale

(0.1 A) all at once, as

calculated below.

leCurrentSca

2

A0.1

-15 to 15

(Factory default: 0)

R/W Byte

1B hex VoltageScale Change the voltage scale (V)

all at once, as calculated

below.

leVoltageSca

2

V

-15 to 15

(Factory default: 0)

R/W Byte

1C hex TimeScale Change the time scale (ms)

all at once, as calculated

below.

TimeScale

2

ms

-15 to 15

(Factory default: 0)

R/W Byte

1D hex RefFromNet Current speed command

source

00: Inverter

01: DeviceNet

R Byte

*

1

"Read-only" while the inverter is running.

Loading...

Loading...