6-4

o11

o12

Feedback Input (Pulse count factor 1)

Feedback Input (Pulse count factor 2)

These function codes specify pulse count factors 1 and 2.

Use these function codes when the motor shaft speed differs from the encoder (PG) shaft

speed depending upon a transmission reduction ratio.

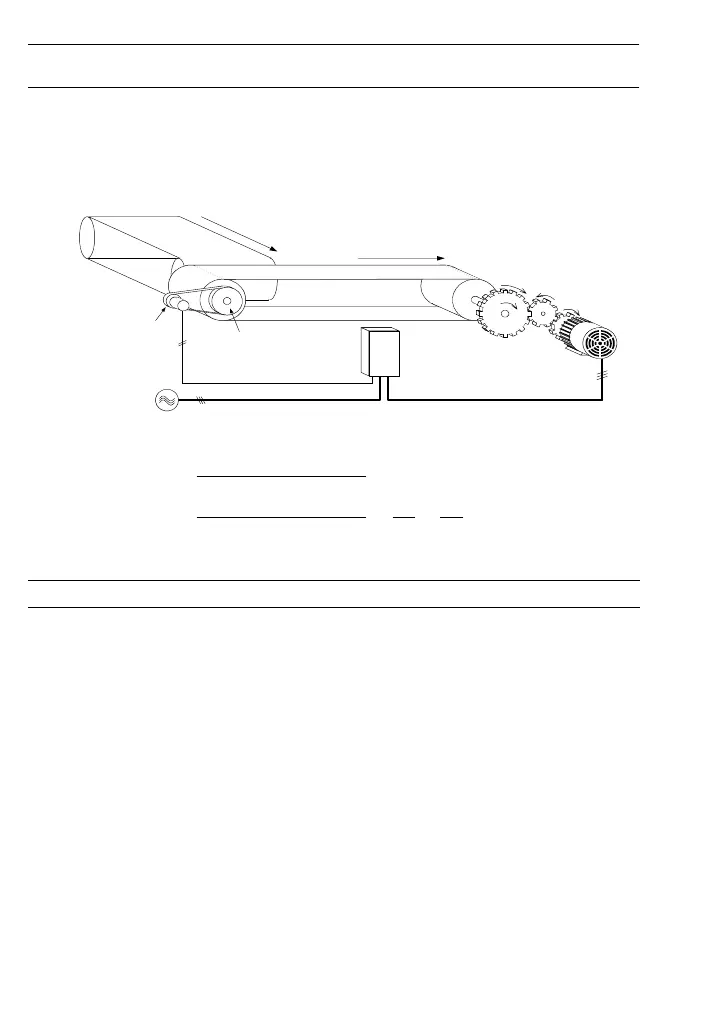

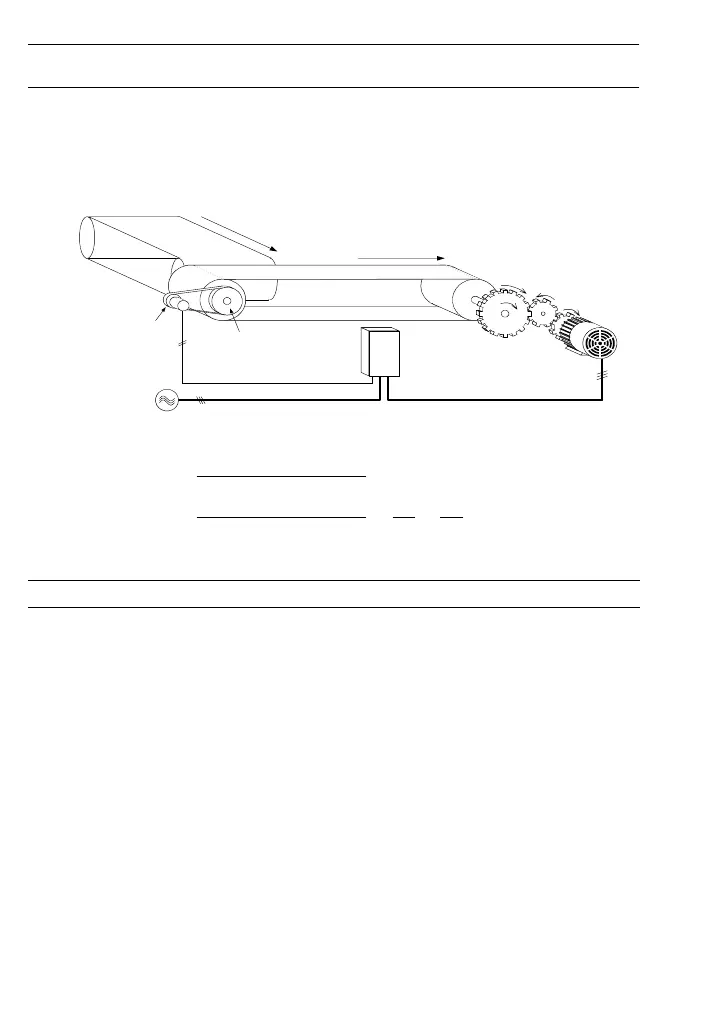

Refer to Figure 6.1 and the expressions below for calculation of the count factors.

[YA],[YB]

Conveyer

Motor

Gear train

(Transmission

ratio: a/b)

Power

supply

L1/R, L2/S, L3/T

Pulley

(Transmission

ratio: c/d)

No. of teeth: b

No. of teeth: a

No. of teeth: a

Radius: c

Radius: d

Inverter

FRN-E1S

PG

U, V, W

Figure 6.1 Speed Control Model Using a PG

Pulse count factor 2 (o12)

Motor shaft speed =

Pulse count factor 1 (o11)

× Encoder shaft speed

Pulse count factor 2 (o12) b d

Pulse count factor 1 (o11)

=

a

×

c

o13 Speed Control (Output limiter)

This function code specifies the output limit percentage for the speed controller (PI controller).

Specification of 100.00% is equivalent to the maximum speed (maximum frequency).

To suppress the frequency control amount (PI controller output) to the extent of the motor's

slip frequency in the speed control mode, use this function.

Loading...

Loading...