6. SYSTEM DESIGN

SELECTION OF PIPE HEAT INSULATING MATERIAL2-4.

Always insulate the refrigerant pipe to prevent condensation and water droplets by the refrigerant

pipe.

Decide the thickness of the heat insulating material by referring to the recommended minimum

thicness in abe . or instaation condition huidit huidit

huidit huidit

When the outdoor unit is installed in a higher position than the indoor unit, fill the connecting part

gap with putty, etc. to prevent the dew condensation water of the valve of the outdoor unit from

flowing to the indoors from the gap between the pipe and the heat insulating material.

Liquid pipe and gas pipe should be completely insulated with same specification.

In case not to insulate and not to seal refrigerant pipe completely, it will become the cause of

water leak.

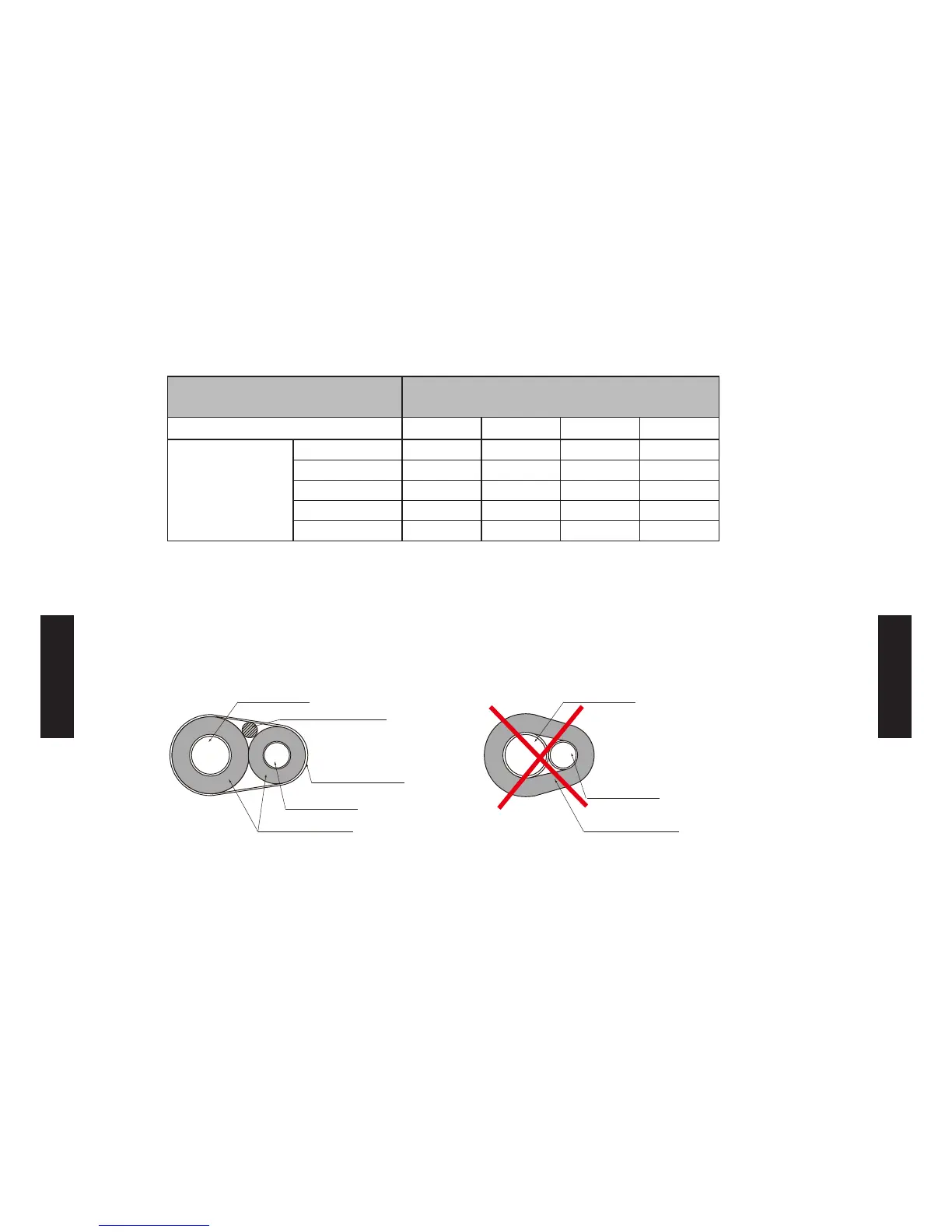

Table1 Size of refrigerant pipe and recommended minimum thickness of heat insulating

material

(In case a heat insulating material which thermal conductivity is equal to or less than 0.040 W/(m·k) is

used. )

Recommended minimum thickness for heat

insulating material (mm)

Relative humidity

Refrigerant pipe

Outside diameter

mm (in.)

6.35 (1/4") 8 10 13 17

9.52 (3/8") 9 11 14 18

12.70 (1/2") 10 12 15 19

15.88 (5/8") 10 12 16 20

19.05 (3/4") 10 13 16 21

When an ambient temperature and relative humidity exceed 32°C DB and 85% respectively,

please strengthen heat insulation of refrigerant pipe. If necessary put a heat insulation on indoor

unit casing. When not strengthening heat insulation of refrigerant pipe, the surface of the heat

insulation may be dewed.

Since gas pipe becomes high temperature at heating operation for heatpump type, please select

the heat insulating material which heat-resistant temperature is 120°C or more.

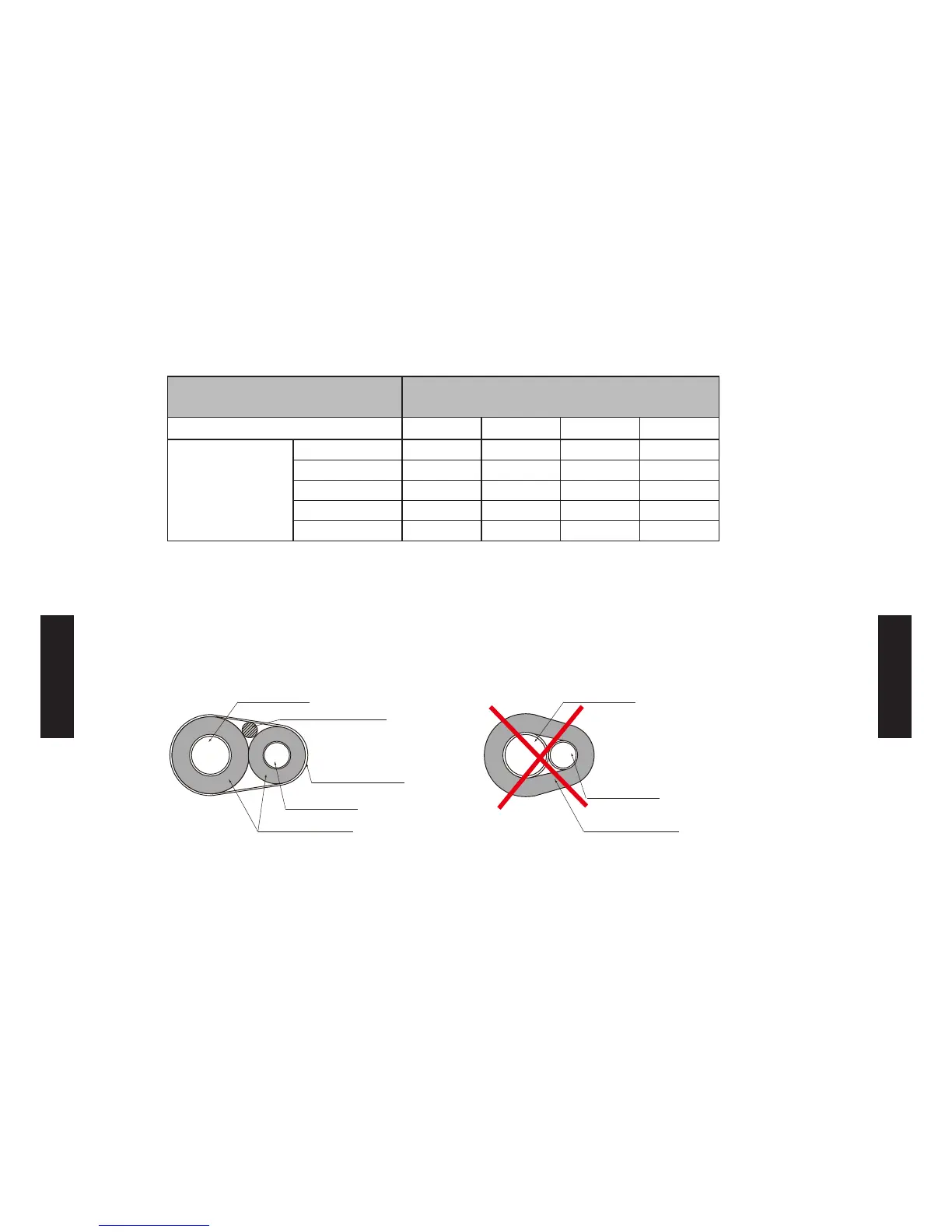

Gas pipe Gas pipe

Connection cable

Finishing tape

Heat insulation Heat insulation

Liquid pipe

Liquid pipe

Make sure that pipe is covered completely by the heat insulation,not exposing to air. Inadequate

heat insulation may cause condensation.

Do not cover heat insulation gas and liquid pipes together as above figure. It may cause

condensation and capacity drop by heat loss.

- (06 - 17) -

SYSTEM

DESIGN

SYSTEM

DESIGN

Loading...

Loading...