16.AUXILIARY FUNCTIONS

The RCK-862 plus allows configuring some complementary functions to control the Rack system. The Pump Down and Compressor protection

thermostat logic apply to suctions. The logic of adiabatic condensation and floating condensation apply to discharges and aims to adjust the Rack to

work with less energy consumption. The individual pressure switch logics allow to control up to 3 pressure switches independently from the main control

of the Rack.

The individual thermostat logic allows controlling the temperature individually or linked with a suction pressure switch, as well as perform defrost logics

based on time.

The logic of rotating outputs allows you to cycle the actuation of outputs based on time. And the Control Status Logic allows to link a digital output to

indicate the activate of the control.

16.1 Pump down:

Pump Down allows the cooling groups to be turned off with refrigerant collection. When Pump Down is activated, the control switches off the last

compressor of each suction at a lower pressure setpoint than the operating pressure setpoint, thus reducing the amount of refrigerant stores in the

suction lines. The control output used for the Pump Down process is optional and has the opposite behavior - during normal operation it remains active,

and when the Pump Down is activated, the output is turned off. In this casem a normally closed solenoid valve can be used to control the passage of the

refrigerant. To configure Pump Dow, access menu 1.7.1. The allows shutdown with Pump Down to be done manually or RCK-862 plus

automatically.

Manual shutdown is done via the Control Menu - Pump Down. The moment the command to perform the recoil is sent, the outlet is turned off and the

refrigerant flow is blocked. The last compressor of each suction line remains operating until the suction pressure reaches the value set in ‘’Pump Down

Setpoint’’ (1.7.1.x.2) or until the time configured in ‘’Maximum Pump Down Time’’ (1.7.1.x.3). The output remains off until a new command

is sent to exit the Pump Down condition.

The automatic shut-off is done on each suction line through a link with one or more thermostats. The thermostats are responsible for commanding the

start of the shutdown by Pump Down and the return of the state of Pump Down releasing to actuate the compressors.

A link between an external thermostat and a suction line is made by configuring an auxiliary input with the Pump Down function in menu 1.6. To create

a link between an internal thermostat ‘’Individual Thermostat (1.7.6)’’ and a suction line, simply select the suction line in menu 1.7.6.x.7 if

none of the linked thermostats has a demand for cooling, the Pump Down output is turned on and the system returns to normal operation. During the

recoil process, low pressure and critical overheat, low and high alarms remain off.

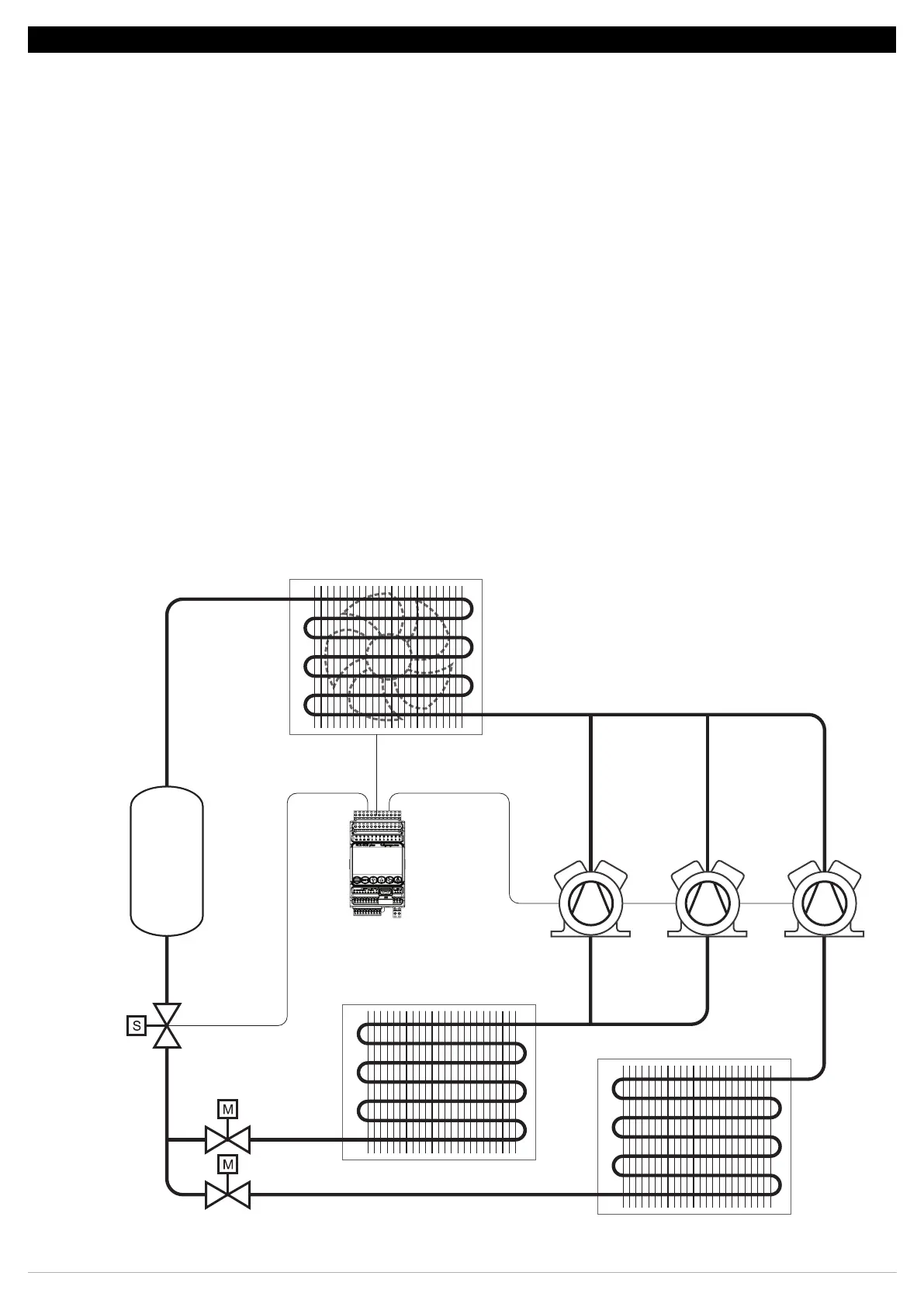

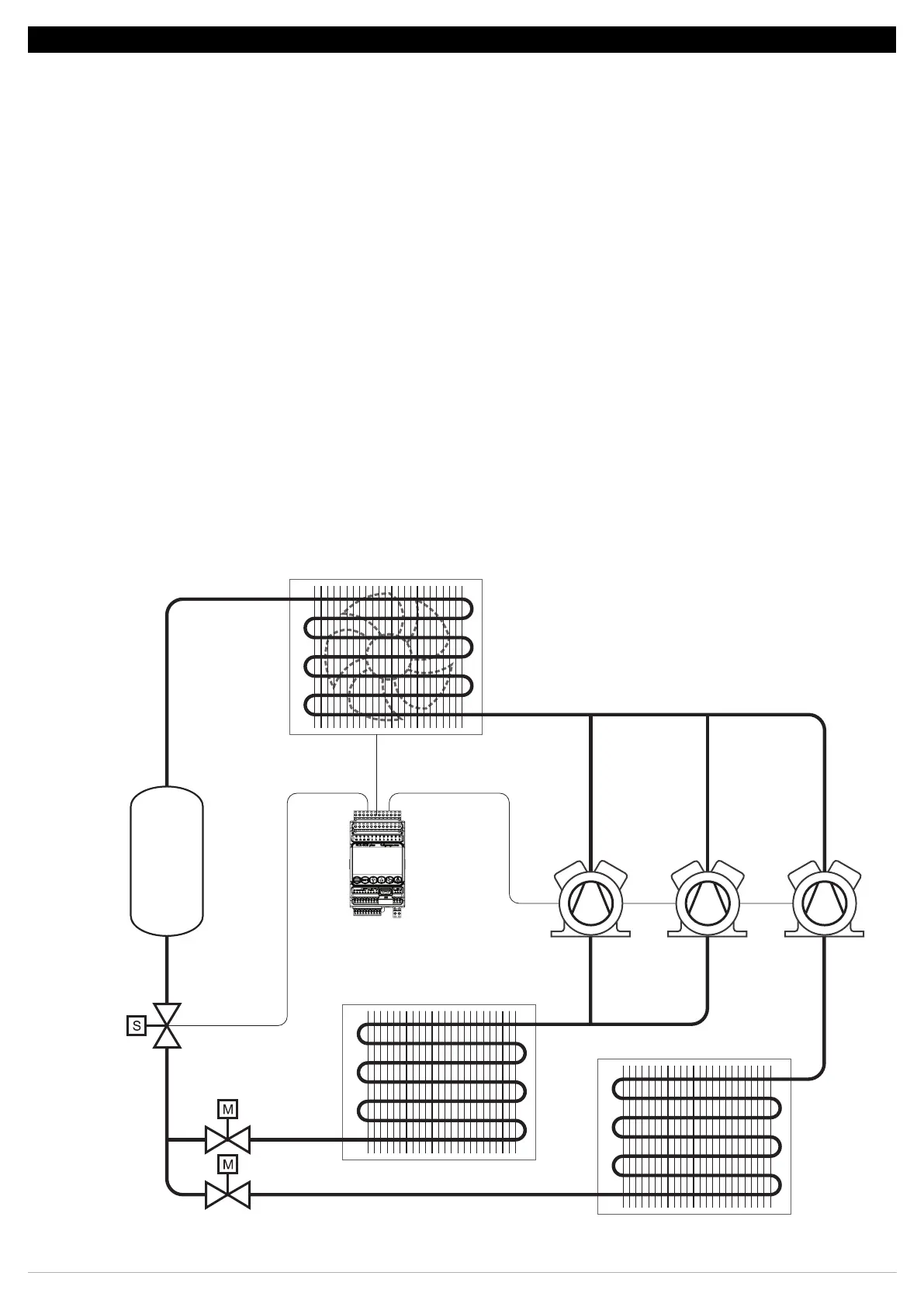

Condenser

Compressors

Liquid

tank

Solenoid

valve

Expansion

valve

Evaporators

31

Loading...

Loading...