30

If you wish to save your changes as a new profile (recommended), you can click “Save as New” instead. This will

prompt you to name the new profile and will add a new entry to the drop-down list.

7.3.4 Commonly Adjusted Parameters

Most of our profiles do not have different quality levels specified. So in order to print at different layer heights,

speeds, etc you will need to make those changes yourself. Some of the commonly adjusted parameters are:

Layer height; how tall each layer of plastic will be. Smaller layers look better (smaller stair-steps) but will

take longer

Infill; how dense the internal lattice inside the part is. Denser is stronger but will take longer.

Speed; how fast the print head moves. Faster will take less time, but at the loss of some surface finish.

This does not have as big an impact on print time as you might think – start with using taller layers if you

want to save time.

Support material settings (see section 7.5)

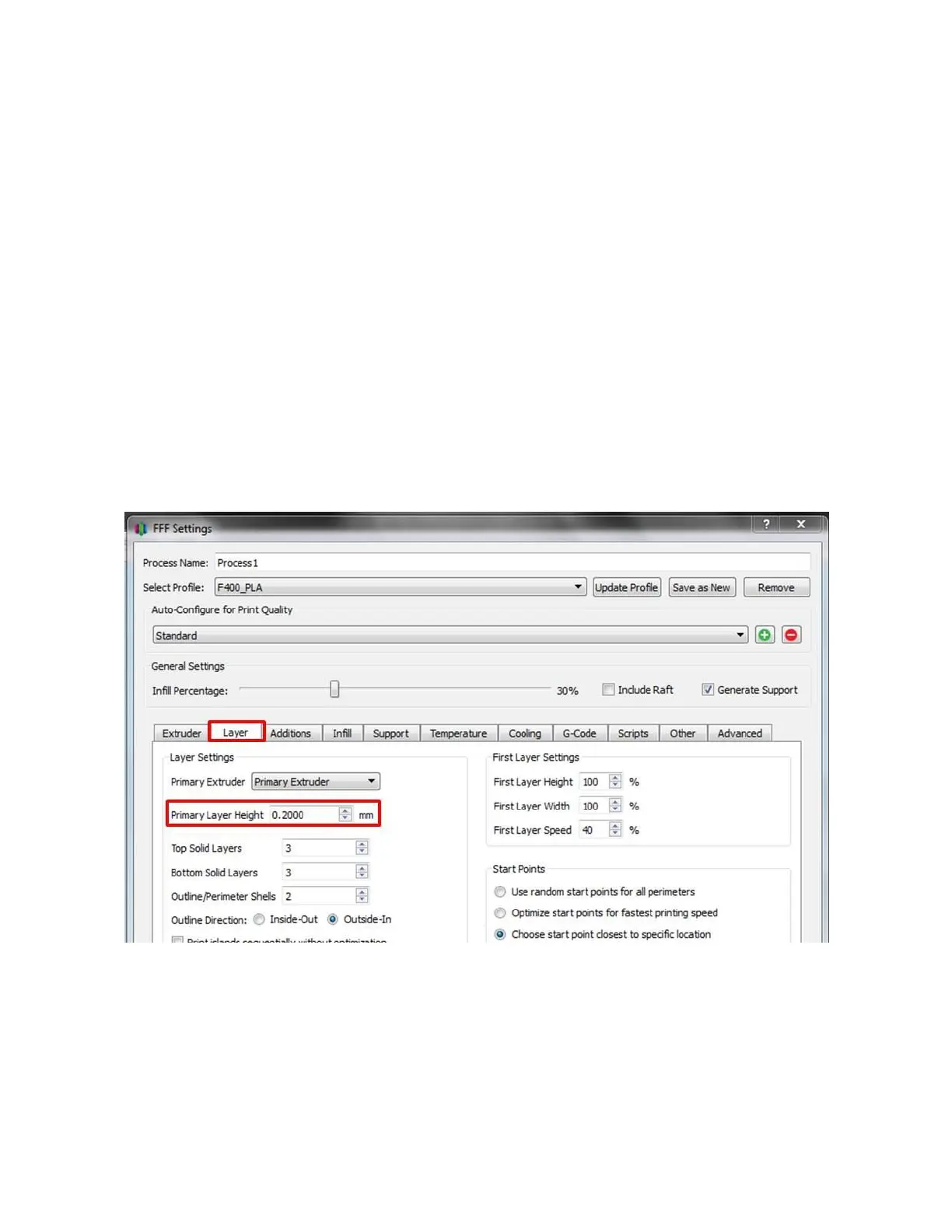

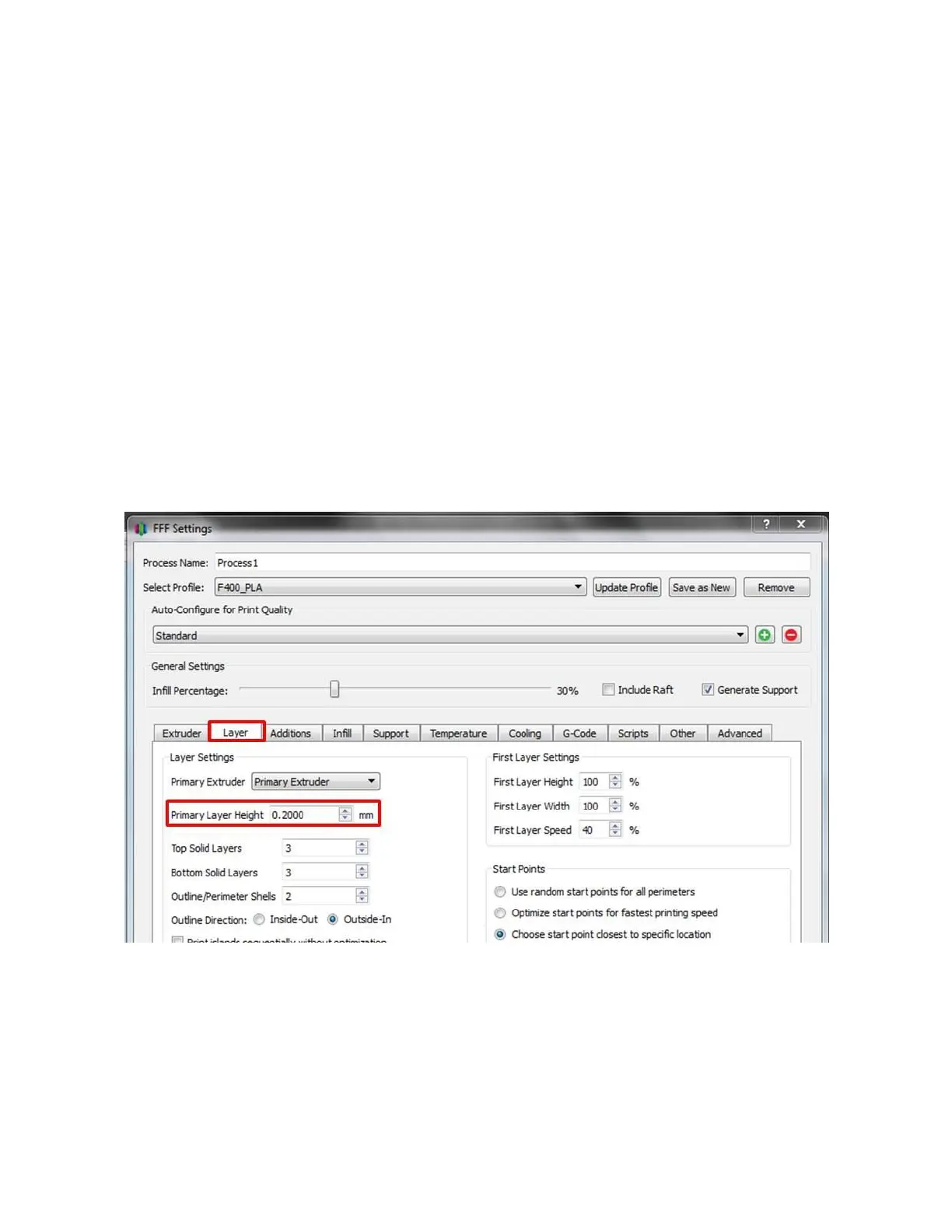

Layer Height

This is adjusted on the “Layer” tab. Values between 0.1 and 0.3 should work for most materials. If you use small

values such as 0.05 please be prepared to adjust other parameters such as speed in order to achieve good results.

Infill

Infill amount can be adjusted via the slider at the top. More detailed settings are found on the “Infill” tab. On this

tab you can also change the infill type. Certain types of infill, such as full hexagonal and grid, can be stronger than

rectilinear but also have downsides. Hex is slow, and grid will overfill small cross sections.

Loading...

Loading...