M

OUNTING THE

M

AGNET AND

S

ENSOR

M

OUNTING THE

M

AGNET AND

S

ENSOR

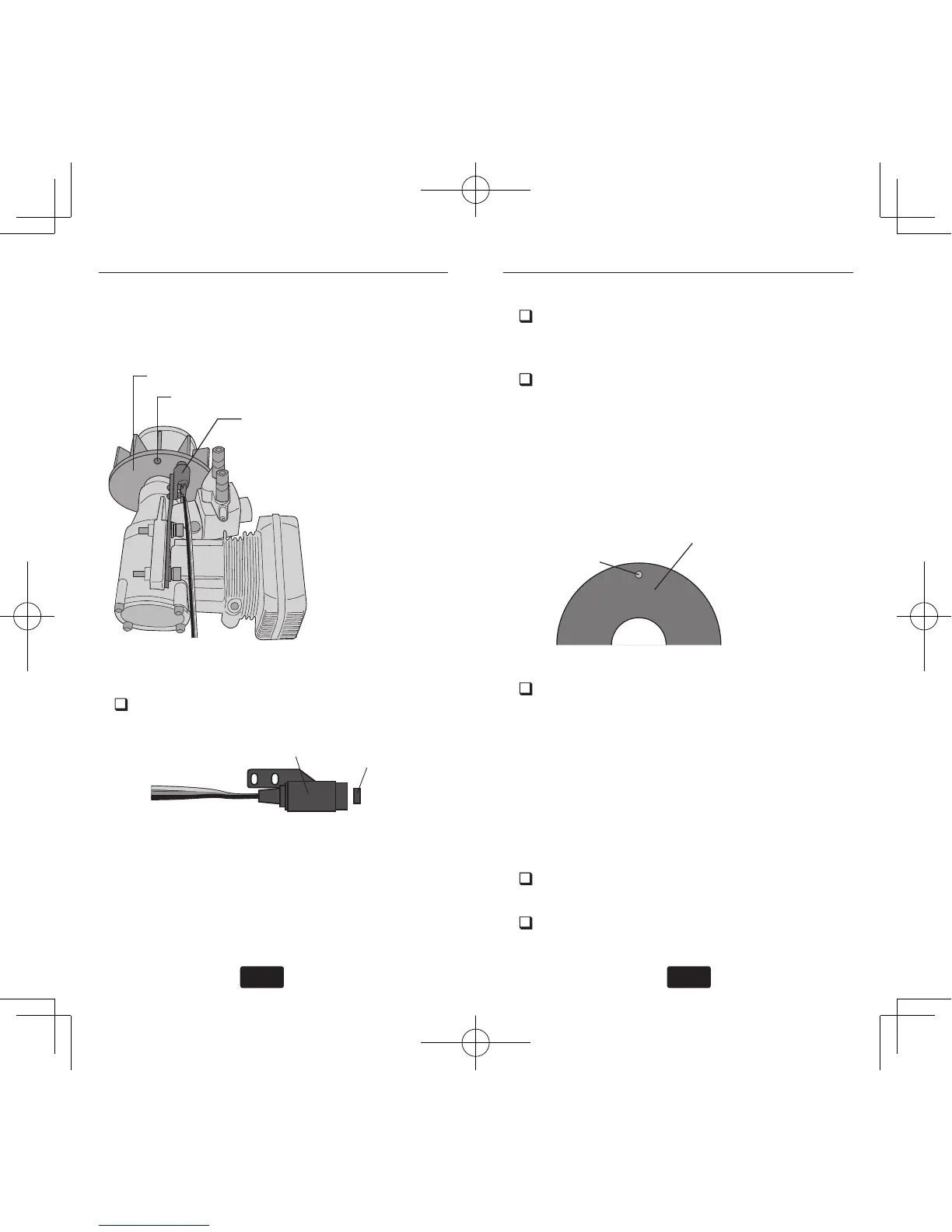

Modify the cooling fan and install the accessory

magnet and attach the magnetic sensor to the en-

gine at the position shown below.

Cooling fan

Magnet (Embedded in cooling fan.)

Sensor (Attached to engine flange

through a stay.)

When installing the sensor mag-

net to the mufer side, also refer

to the needle side mounting.

Cooling fan modication

Drill a hole in the fan at the magnet mount-

ing position. Make the hole about 4.1mm in

diameter and 1.5 to 1.7mm deep.

Embed the magnet in this hole in the direc-

tion in which an output is obtained. Use

epoxy adhesive that cures in 30 minutes or

longer. Do not use epoxies that contain metal

such as JB Weld.

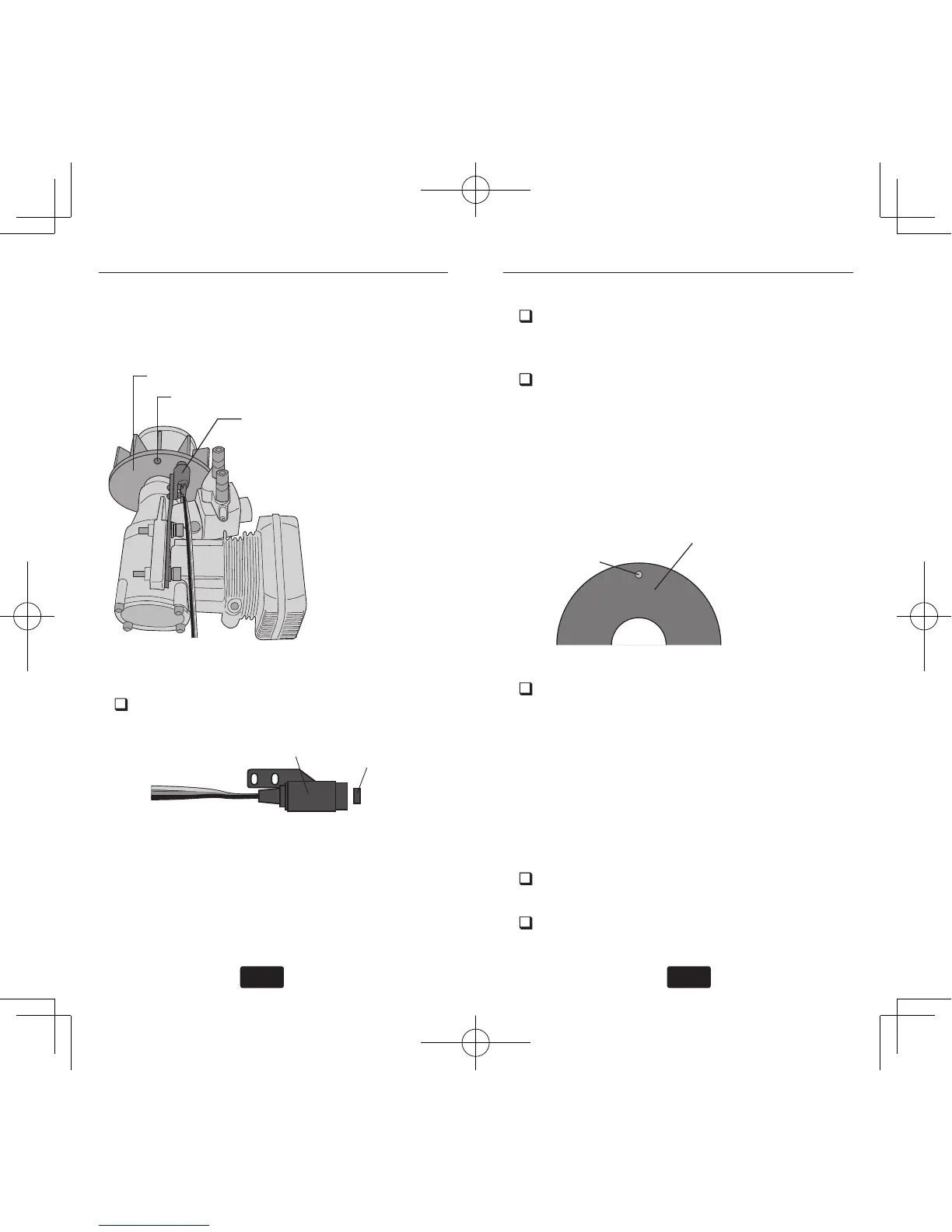

Magnet

Cement the magnet to the cooling

fan so that the magnet is level

with this side of the cooling fan.

If the cooling fan is unbalanced and vibrates,

etc., balance it by mounting the spare magnet

to the opposite side of the cooling fan in the

opposite polarity (so that it does not output a

signal).

Sensor mounting

The sensor mounting method depends on the heli-

copter and engine.

Mount the sensor to the sensor stay. (Tempo-

rary assembly)

Drill a hole in the fan cover at the part cor-

responding to the sensor so that the distance

Magnet operating side check

Bring the magnet near the end of the sensor

and check the operating side.

This is the side at which the displayed value

increases in the “Revolution sensor testing”

menu within the “Governor Basic Setting”

section earlier in this manual. Install the mag-

net with this side facing the sensor. Mark this

side of the magnet with a felt tip pen.

Loading...

Loading...