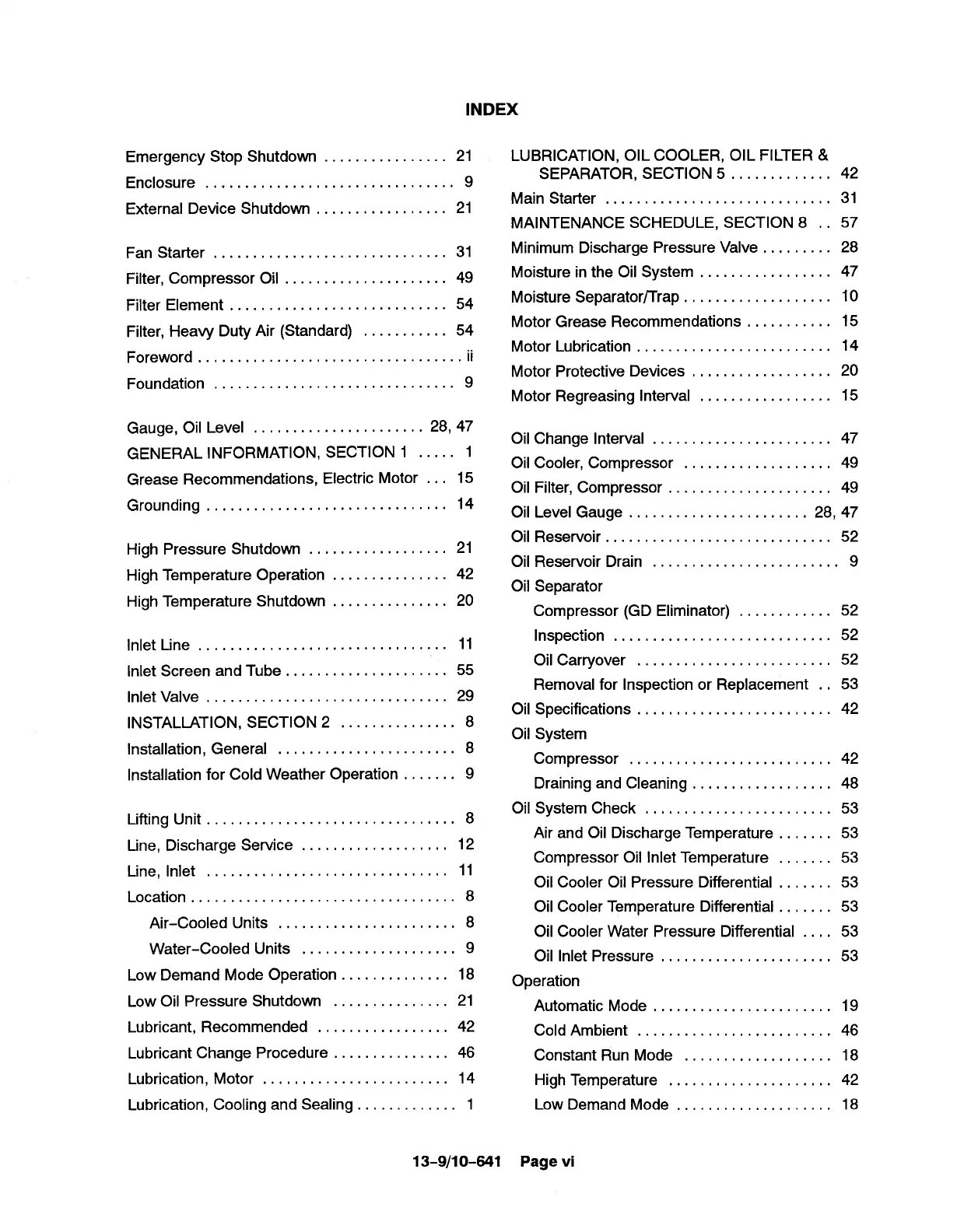

Emergency Stop Shutdown . . . . . . . . . . . . . . . . 21

Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9

External Device Shutdown . . . . . . . . . . . . . . . . . 21

Fan Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . ...31

Filter, Compressor Oil . . . . . . . . . . . . . . . . . . ...49

Filter Element . . . . . . . . . . . . . . . . . . . . . . . . . ...54

Filter, Heavy DutyAir (Standard) . . . . . . . . . . . 54

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..ii

Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9

Gauge, Oil Level . . . . . . . . . . . . . . . . . . . ...28.47

GENERAL INFORMATION, SECTION 1 . . . . . 1

Grease Recommendations, Electric Motor . . . 15

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

High Pressure Shutdown . . . . . . . . . . . . . . . . . . 21

High Temperature Operation . . . . . . . . . . . . . . . 42

High Temperature Shutdown . . . . . . . . . . . . . . . 20

Inlet Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

inlet Screen and Tube . . . . . . . . . . . . . . . . . . ...55

Inlet Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...29

INSTALLATION, SECTION2 . . . . . . . . . . . . . . . 8

installation, General . . . . . . . . . . . . . . . . . . . . . . . 8

installation for Cold Weather Operation . . . . . . . 9

Lifting Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Line, Discharge Service . . . . . . . . . . . . . . . . . . . 12

Line, inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Air-Cooled Units . . . . . . . . . . . . . . . . . . . . ...8

Water-Cooled Units . . . . . . . . . . . . . . . . . . . . 9

Low Demand Mode Operation.. . . . . . . . . . . . . 18

Low Oil Pressure Shutdown . . . . . . . . . . . . . . . 21

Lubricant, Recommended . . . . . . . . . . . . . . . . . 42

Lubricant Change Procedure.. . . . . . . . . . . . . . 46

Lubrication, Motor . . . . . . . . . . . . . . . . . . . . . . . . 14

Lubrication, Cooling and Sealing. . . . . . . . . . . . . 1

LUBRICATION, OIL COOLER, OIL FILTER &

SEPARATOR, SECTION 5 . . . . . . . . . . . . . 42

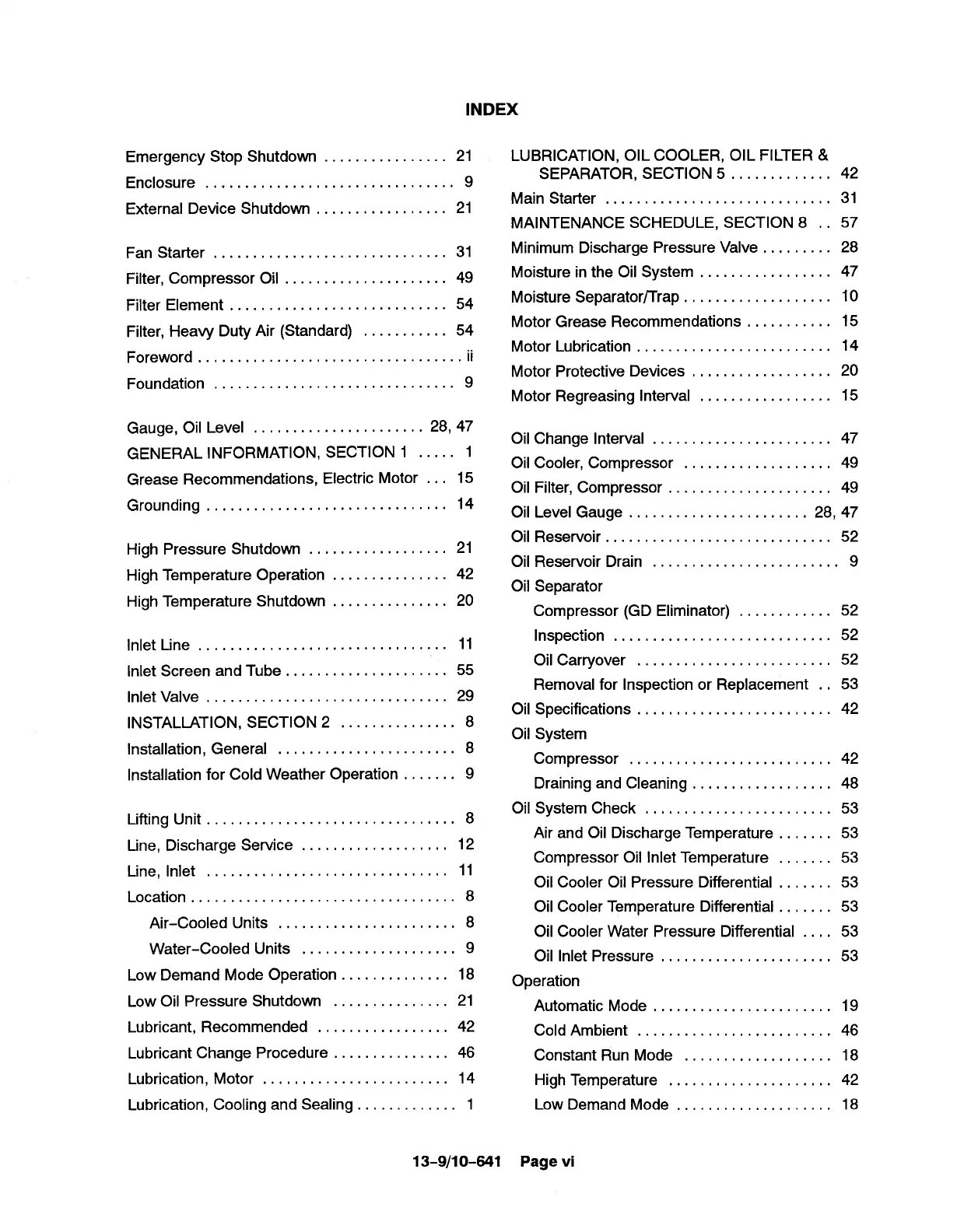

Main Starter . . . . . . . . . . . . . . . . . . . . . . . . . . ...31

MAINTENANCE SCHEDULE,SECTION 8 . . 57

Minimum Discharge Pressure Valve . . . . . . . . . 28

Moisture in the Oil System . . . . . . . . . . . . . . . . . 47

MoistureSeparator/Trap . . . . . . . . . . . . . . . . . . . 10

Motor Grease Recommendations . . . . . . . . . . . 15

Motor Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . 14

Motor Protective Devices . . . . . . . . . . . . . . . . . . 20

Motor Regreasinglnterval . . . . . . . . . . . . . . . . . 15

Oil Change Interval . . . . . . . . . . . . . . . . . . . . . . . 47

Oil Cooler, Compressor . . . . . . . . . . . . . . . . ...49

Oil Filter, Compressor . . . . . . . . . . . . . . . . . . . . . 49

Oil Level Gauge . . . . . . . . . . . . . . . . . . . . ...28.47

Oil Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Oil Reservoir Drain . . . . . . . . . . . . . . . . . . . . . ...9

Oil Separator

Compressor (GD Eliminator) . . . . . . . . . . . . 52

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . ...52

Oil Carryover . . . . . . . . . . . . . . . . . . . . . . ...52

Removal for inspection or Replacement . . 53

Oil Specifications . . . . . . . . . . . . . . . . . . . . .

Oil System

Compressor . . . . . . . . . . . . . . . . . . . . . .

Draining and Cleaning . . . . . . . . . . . . . .

Oil System Check . . . . . . . . . . . . . . . . . . . .

Air and Oil Discharge Temperature ...

Compressor Oil lnletTemperature . . .

Oil Cooler Oil Pressure Differential . . .

Oil CoolerTemperature Differential ...

Oil Cooler Water Pressure Differential

Oil inlet Pressure, . . . . . . . . . . . . . . . . .

Operation

Automatic Mode . . . . . . . . . . . . . . . . . . .

Cold Ambient.............,.. . . . . .

Constant Run Mode . . . . . . . . . . . . . . .

High Temperature . . . . . . . . . . . . . . . . .

Low Demand Mode....,,,,,. . . . . . .

. . . .

42

..,.

42

..,. 48

. . . . 53

. . . .

53

.s.. 53

. . . .

53

..,. 53

. . . . 53

. . . . 53

. . . . 19

. . . . 46

. . . . 18

.,..

42

. . . . 18

13-9/10-641 Pagevi

Loading...

Loading...