CHAPTER 6: SETPOINTS S2 SYSTEM SETUP

345 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL 6–25

Thus, for any load, the Winding 2 CT secondary current is higher (per unit) than the

Winding 1 CT secondary current. The mismatch factor is 1658.6 / 1500 = 1.1057.

The 345 relay calculates the magnitude correction factor for Winding 2 as follows:

Eq. 2

The 345 calculates and automatically corrects the CT mismatch to a maximum mismatch

factor of 16.

Hence, the measured currents from winding 2 will be automatically compensated by the

relay applying the correction factor of 0.904. The currents from winding 1 are not

multiplied by any correction factor, as they are always used by the relay as a magnitude

reference.

Based on 100% transformer loading (5MVA), the measured winding currents are:

Winding 1 CT: measured

Eq. 3

- winding 1 nominal current

Winding 2 CT: measured

Eq. 4

- winding 2 nominal current

Based on 100% transformer loading, the compensated currents expressed in times CT (w1)

as a reference and used by the percent differential protection will be as shown:

Eq. 5

Eq. 6

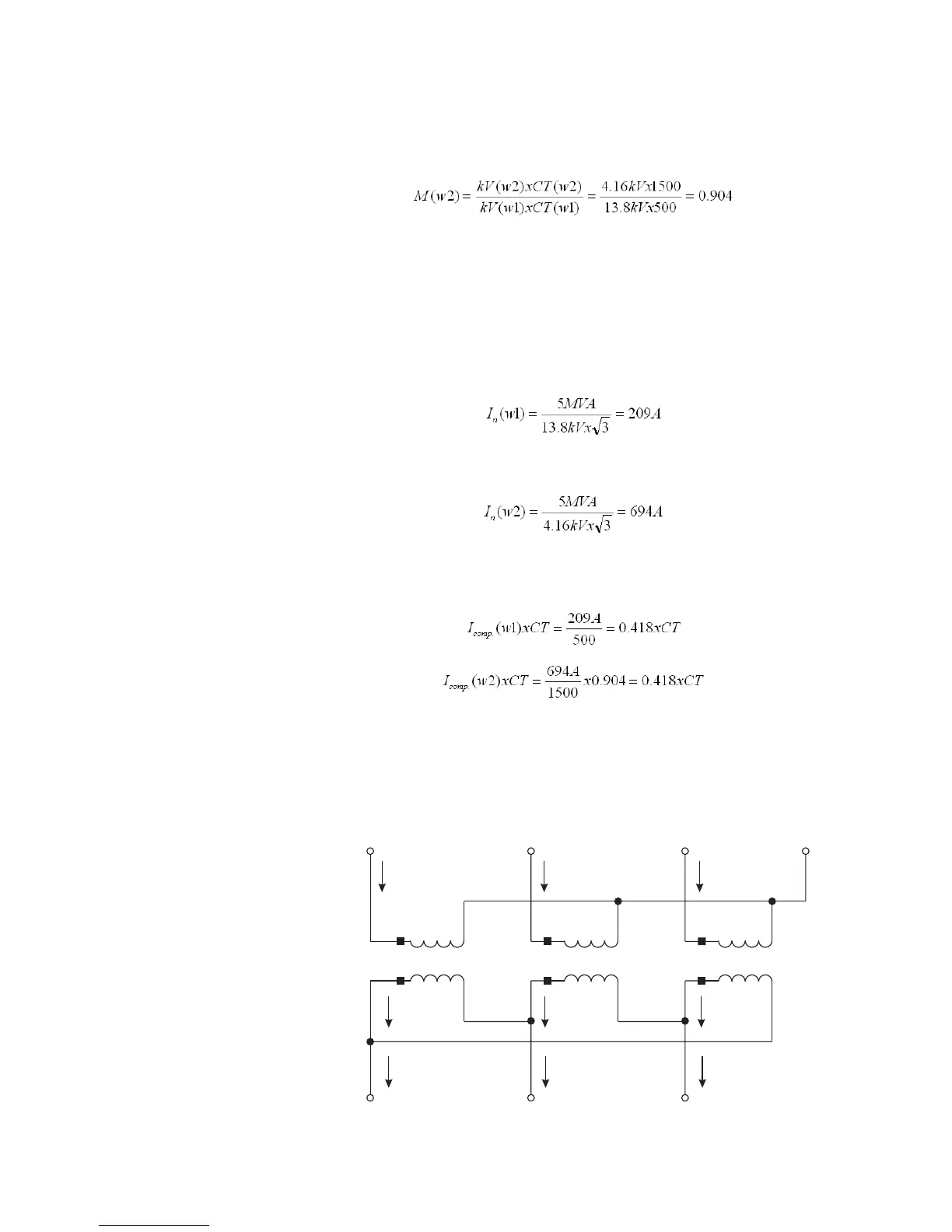

PHASE SHIFT COMPENSATION

The source phase sequence must be stated when describing the winding phase

relationships since these relationships change when the phase sequence changes. The

example below shows why this happens, using a transformer described in IEC

nomenclature as “Yd1” or in GE Multilin nomenclature as “Y/d30.”

Figure 6-12: Example transformer

897716A1.CDR

A

I

A

I'

a

BCN

abc

I

B

I

C

I'

b

I'

c

I=

a

I '–I'

ac

I=

b

I '–I '

ba

I=

c

I'–I '

cb

Loading...

Loading...