5–50 745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL

S4 ELEMENTS CHAPTER 5: SETPOINTS

The basic percent differential operating principle for three-winding transformers is

illustrated by the following equations:

(EQ 5.4)

The basic percent differential operating principle for two-winding transformers is

illustrated by the following equations:

(EQ 5.5)

where I

restraint

= per-phase maximum of the currents after phase, ratio, and zero-

sequence correction;

I

differential

= per-phase vector sum of currents after phase, ratio, and zero-

sequence correction

Note

In the above equations, the 180° phase shift due to the wiring connections is taken into

account, hence the + sign to obtain the differential current.

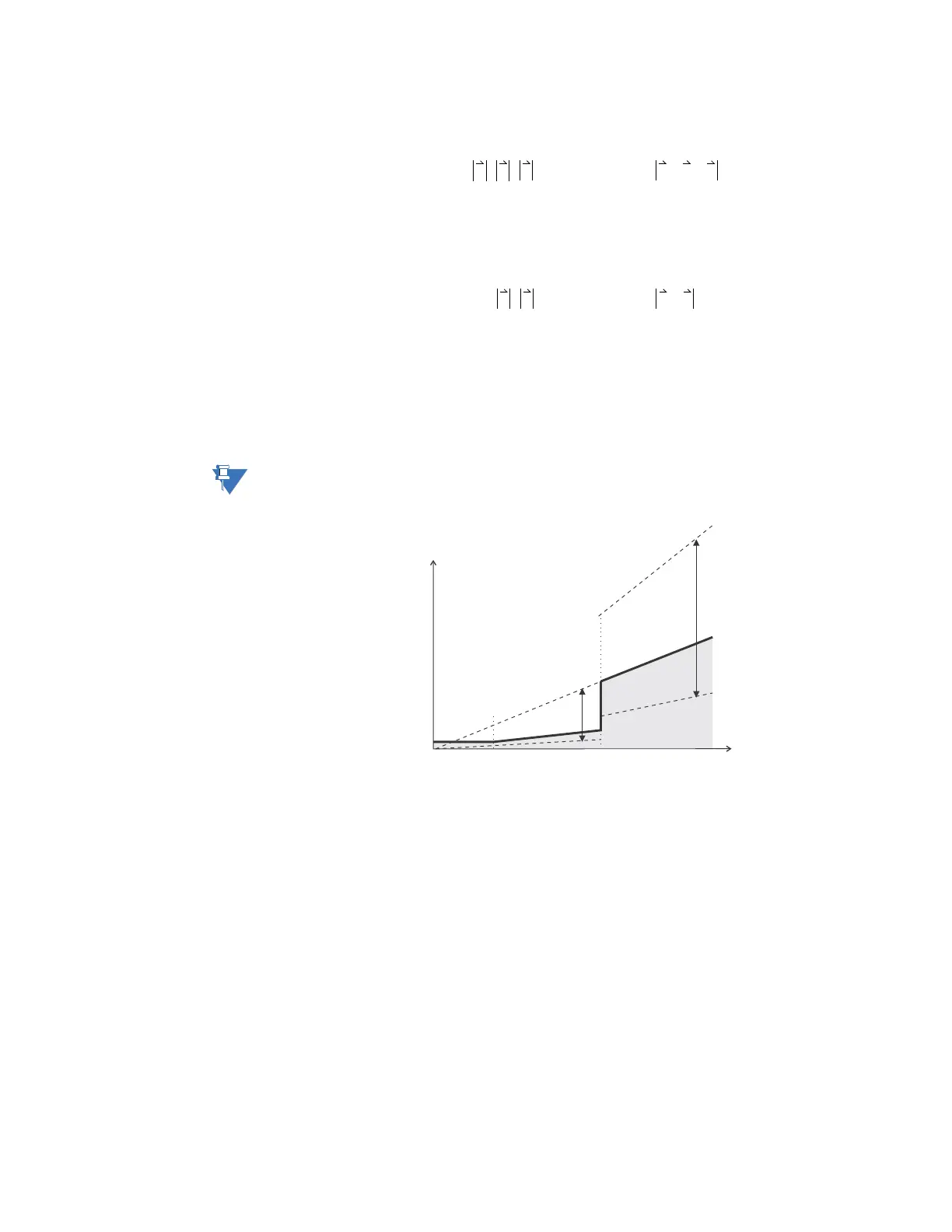

FIGURE 5–8: Percent differential dual-slope characteristic

The base for the percent differential setpoints is the S2 SYSTEM SETUP WINDING 1

WINDING 1 PHASE CT PRIMARY

setpoint value. The percent differential setpoints are

explained below.

• PERCENT DIFFERENTIAL PICKUP: Enter the minimum differential current required for

operation. This setting is chosen based on the amount of differential current that

might be seen under normal operating conditions.

• PERCENT DIFFERENTIAL SLOPE 1: Enter the slope 1 percentage (of differential current

to restraint current) for the dual-slope percent differential element. The slope 1 setting

is applicable for restraint currents of zero to the kneepoint, and defines the ratio of

differential to restraint current above which the element will operate. This slope is set

to ensure sensitivity to internal faults at normal operating current levels. The criteria

for setting this slope are:

I

r

I

restraint

max I

1

I

2

I

3

,,()== ; I

d

I

differential

I

1

I

2

I

3

++==

%slope

I

d

I

r

----

100%×=

I

r

I

restraint

max I

1

I

2

,()== ; I

d

I

differential

I

1

I

2

+==

%slope

I

d

I

r

----

100%×=

100%

OPERATE

REGION

RESTRAINT

REGION

SLOPE 1

25%

SLOPE 2

100%

200%

50%

I (x CT)

restraint

I (x CT)

differential

15%

0.05

1.00

PICKUP 0.30

2.0

KNEEPOINT

Loading...

Loading...