CHAPTER 1: OVERVIEW INTRODUCTION

PQM POWER QUALITY METER – INSTRUCTION MANUAL 1–3

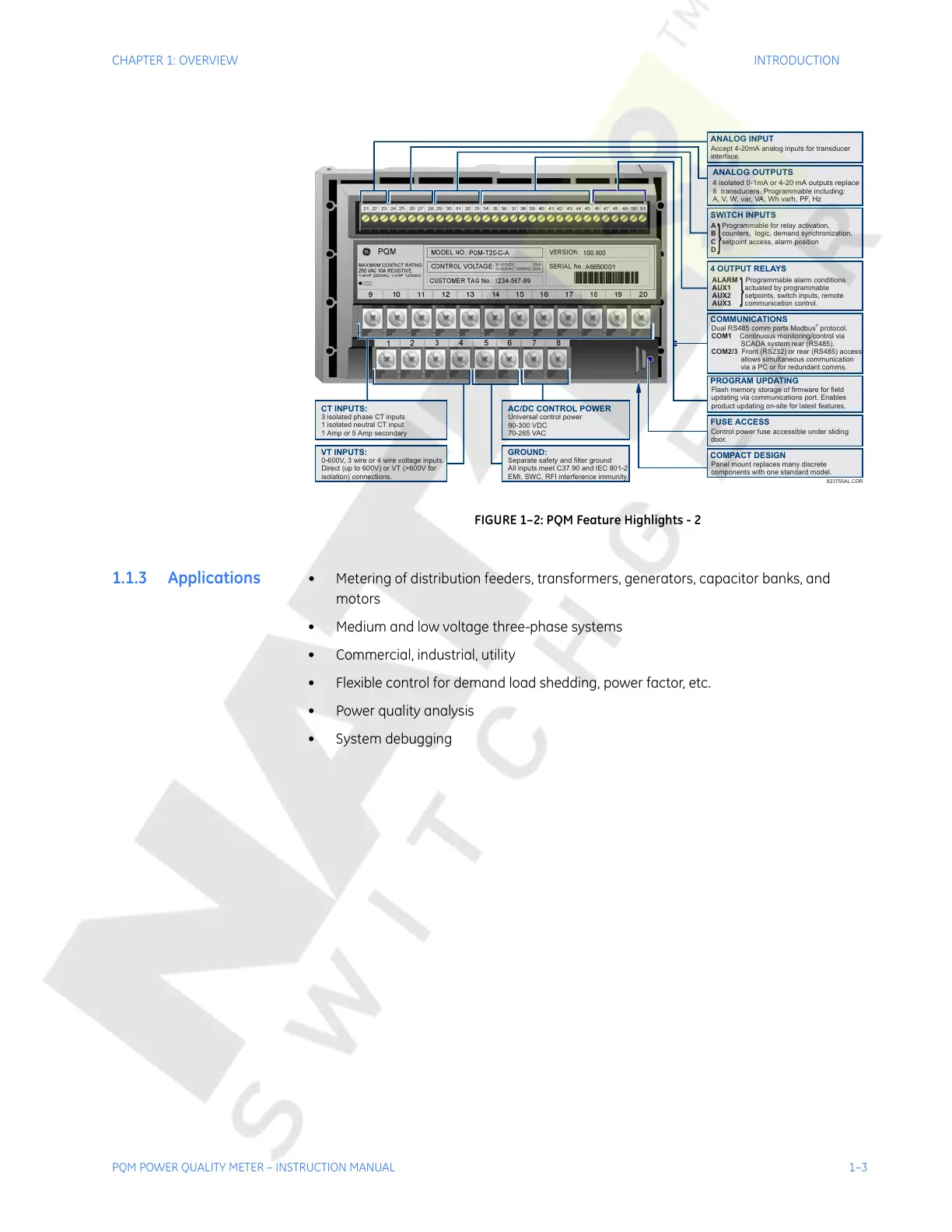

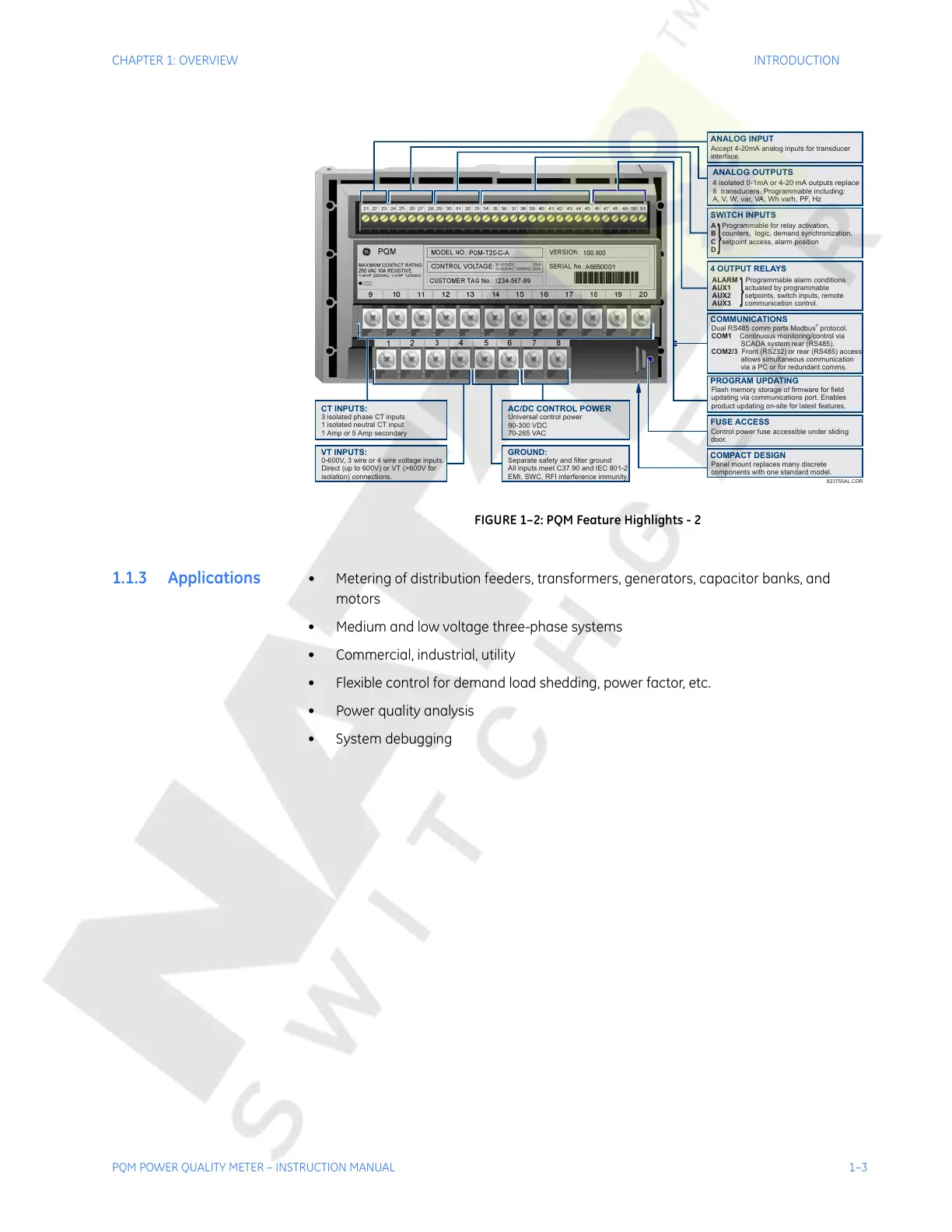

FIGURE 1–2: PQM Feature Highlights - 2

1.1.3 Applications • Metering of distribution feeders, transformers, generators, capacitor banks, and

motors

• Medium and low voltage three-phase systems

• Commercial, industrial, utility

• Flexible control for demand load shedding, power factor, etc.

• Power quality analysis

• System debugging

823755AL.CDR

FUSE ACCESS

ANALOG INPUT

Control power fuse accessible under sliding

door.

Accept 4-20mA analog inputs for transducer

interface.

VT INPUTS:

0-600V,3wire or 4 wire voltage inputs.

Direct (up to 600V) or VT (>600V for

isolation) connections.

CT INPUTS:

GROUND:

3 isolated phase CT inputs

1 isolated neutral CT input

1 Amp or 5 Amp secondary

Separate safety and filter ground

All inputs meet C37.90 and IEC 801-2

EMI,SWC, RFI interference immunity.

AC/DC CONTROL POWER

Universal control power

90-300 VDC

70-265 VAC

COMPACT DESIGN

Panel mount replaces many discrete

components with one standard model.

PROGRAM UPDATING

Flash memory storage of firmware for field

updating via communications port.Enables

product updating on-site for latest features.

COMMUNICATIONS

Dual RS485 comm ports Modbus protocol.

Continuous monitoring/control via

SCADA system rear (RS485).

Front (RS232) or rear (RS485) access

allows simultaneous communication

via a PC or for redundant comms.

®

COM1

COM2/3

ANALOG OUTPUTS

4isolated 0-1mA or 4-20 mA outputs replace

8 transducers. Programmable including:

A, V, W, var, VA, Wh varh, PF, Hz

SWITCHINPUTS

A

B

C

D

Programmable for relay activation,

counters, logic, demand synchronization,

setpoint access, alarm position

4 OUTPUT RELAYS

ALARM

AUX1

AUX2

AUX3

Programmablealarm conditions

actuated by programmable

setpoints, switch inputs, remote

communication control.

}

}

Courtesy of NationalSwitchgear.com

Loading...

Loading...