How to resolve Temperature Input Supply issues in GE Transport PT878 Measuring Instruments?

- MMorgan OnealSep 12, 2025

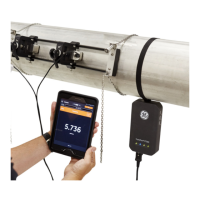

If you are experiencing issues with the Temperature Input Supply on your GE Measuring Instruments, which indicates that the supply temperature input is out of range, check the cable and transmitter for any faults.