Chap. 6 — page 35

L.GEISMAR Company – Prohibited Reproduction©

HYDRAULIC RAIL THREADER H90461 / NO 10055

TYPE MPR – M

This advice is not restrictive. Permanent monitoring of the device as well

as preventive maintenance can only extend its operating life.

6 – 2 – 1 Daily maintenance

PUMP UNIT

For motor servicing, see the HATZ service brochure included in the appendix

Grease used: IMPERATOR LC 3002 Multifunction Grease

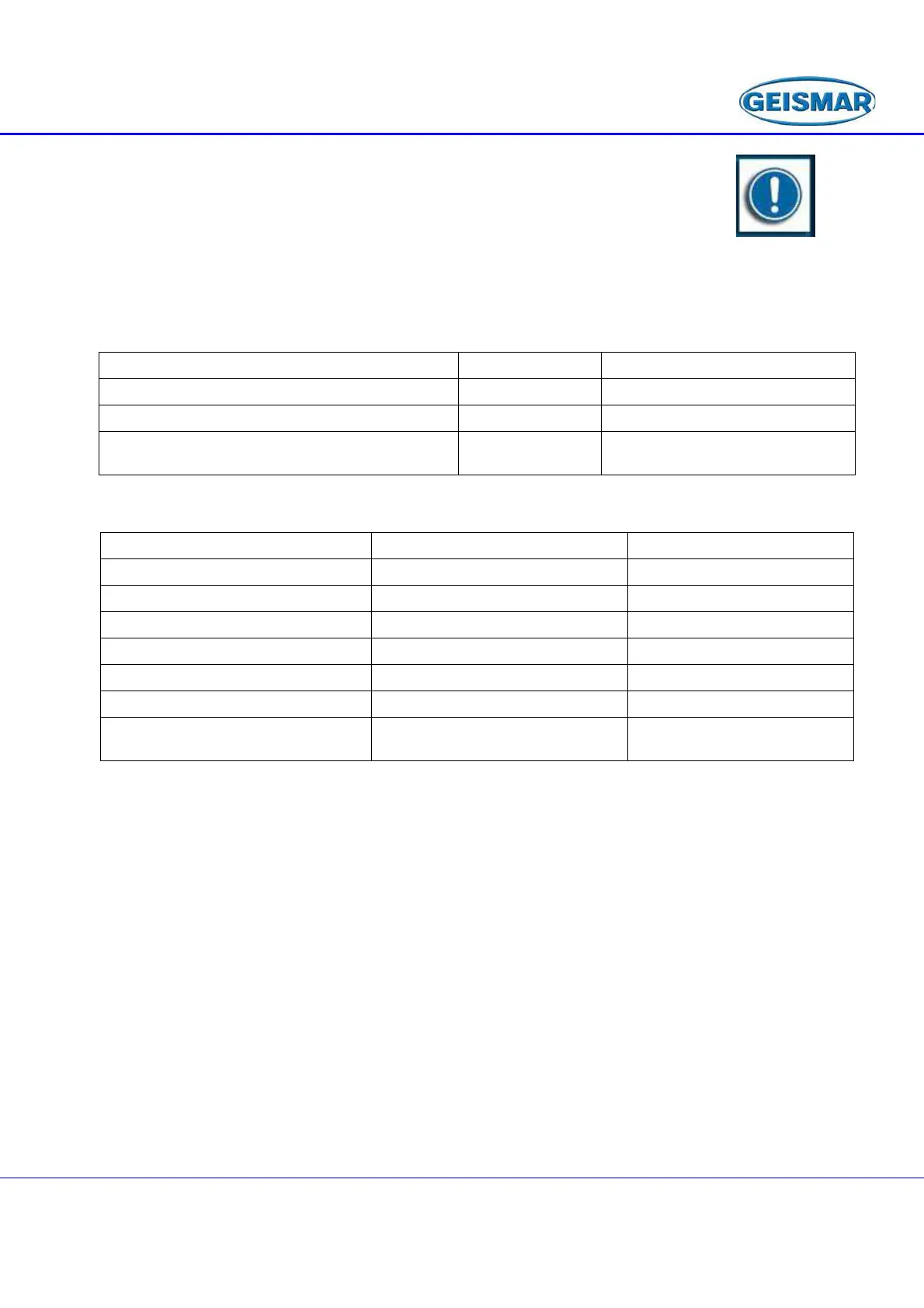

T

ABLE OF FILLING SPECIFICATIONS

CORRESPONDENCE TABLE OF OILS AND GREASES

6 – 3 Interventions after commissioning

AFTER THE FIRST 10 OPERATING HOURS

Make sure all the bolts are tight

Check the hydraulic oil level (fig. 6.1.1.a), and top up if necessary.

A

FTER THE FIRST 25 OPERATING HOURS

Drain the motor oil with the motor hot to facilitate flow, and change the oil filter.

(see brochure provided in the appendix)

A

FTER THE FIRST 50 OPERATING HOURS

Replace the cartridge in the hydraulic circuit.

Start the pump unit supplying the hydraulic circuit.

Run it for 10 minutes and make sure there are no oil leaks in the hydraulic circuit:

connectors, pipes, hoses, hydraulic components, pumps and wheel motors.

Switch off the hydraulic power unit.

Remove the cartridge from the hydraulic circuit return filter

T

ANK VOLUME QUALITY TYPE

MOTOR FUEL HATZ 1-D41C 15 L DIESEL

MOTOR GREASING HATZ 1-D41C 1.2 L SEE SPECIFIC MANUAL

HYDRAULIC OIL 50 L

SEE TABLE OF OILS AND

LUBRICANTS

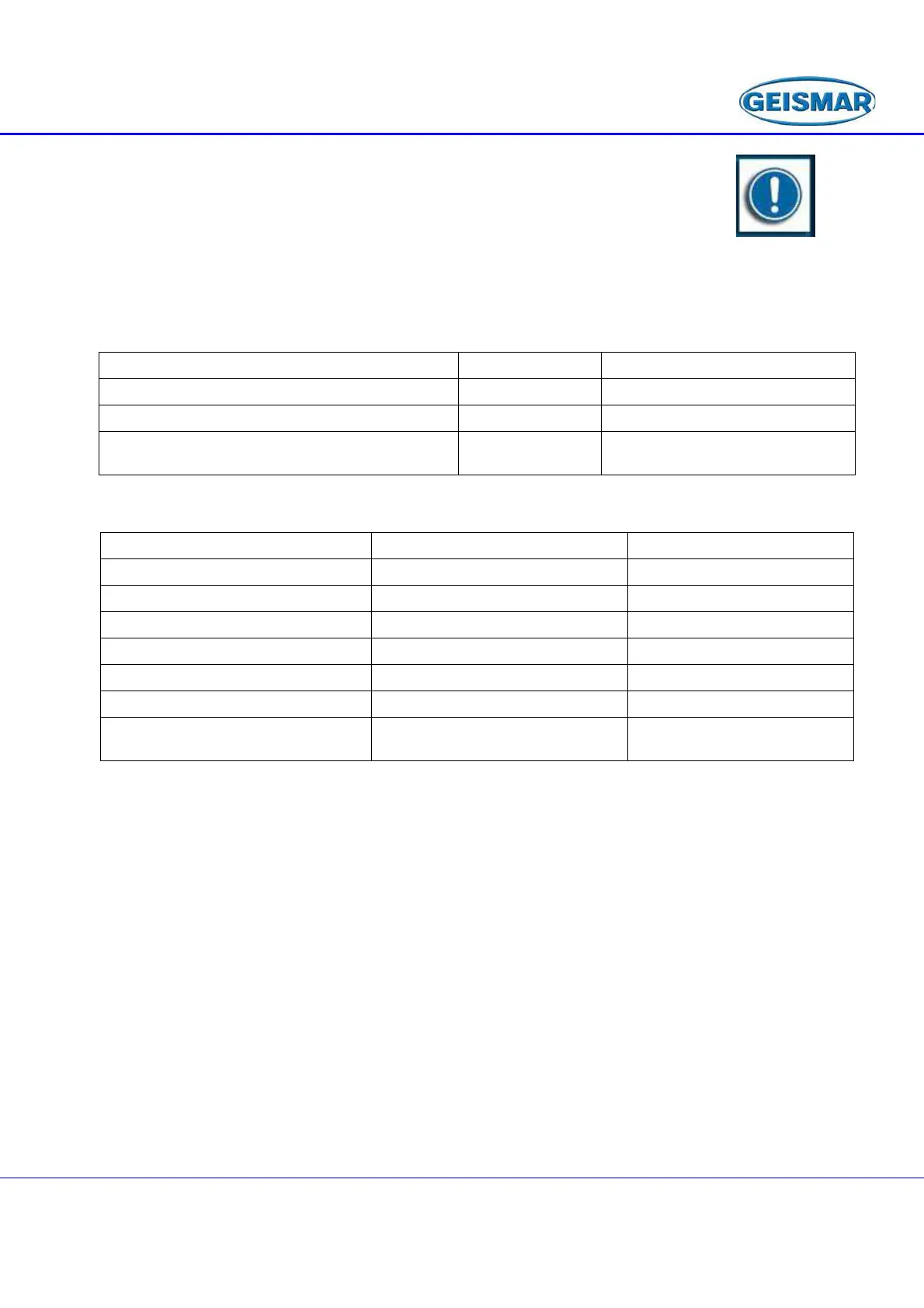

BRAND HYDRAULIC OIL GREASING

MOBIL DTE 13M

BP BARTRAN HV32 ENERGREASE LC 2

CASTROL HYSPIN AWH M32 LM GREASE

SHELL TELLUS T 32 ALBIDA HD 2

TEXACO RANDO OIL HD Z-36 HYTEX EP 2

ELF VISGA 36 MULTIPLEX

TOTAL EQUIVIS ZS 32

MULTI COMPLEX EP

2

Loading...

Loading...